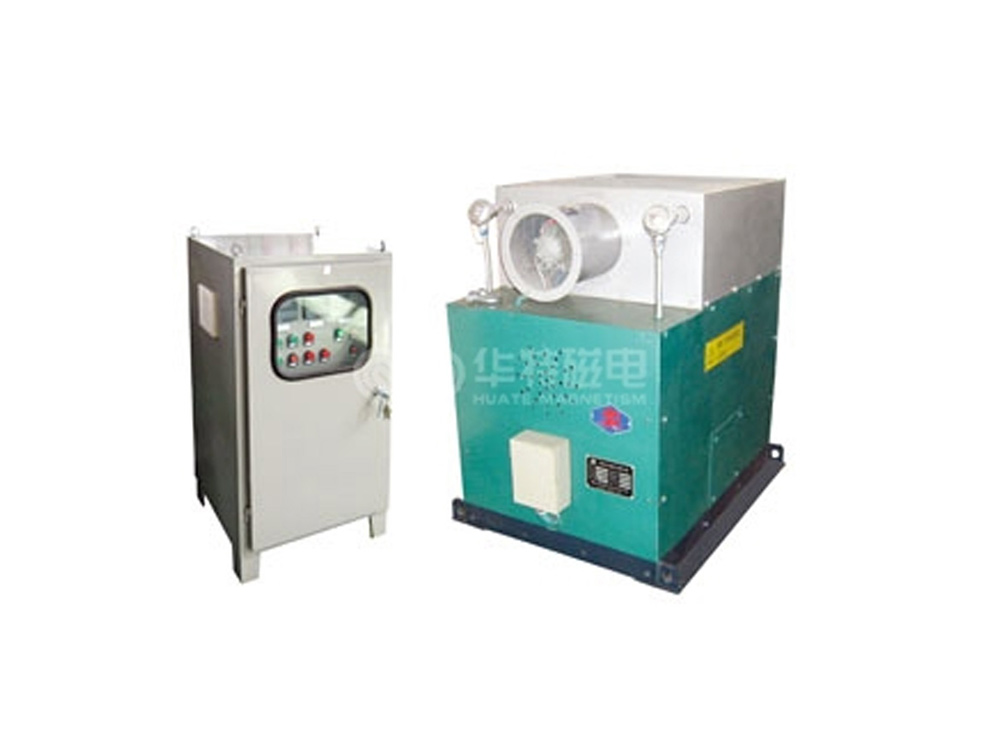

Wholesale ODM China Permanent Magnet Magnetic Material Separator for Processing Various Ore

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for Wholesale ODM China Permanent Magnet Magnetic Material Separator for Processing Various Ore, With advantage of industry management, the business has generally been committed to supporting prospects to become the current market leader in their respective industries.

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for China Wet Magnetic Separator, Overband Magnetic Separator, Our goods have won an excellent reputation at each of the related nations. Because the establishment of our firm. we’ve insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

Features

◆The magnetic system adopts wide and narrow magnetic pole partition arrangement, which is beneficial to improve mineral recovery and concentrate grade.

◆The magnetic package Angle can reach 160°, and the effective sorting line of the drum is 1.2 times of the diameter of the 1.5m drum under the same magnetic package Angle. The inclusion of gangong stone is easier to come out, which improves the sorting effect of the equipment.

◆Tank with overflow outlet, through the replacement of plug-plate throttle valve, adjust the level of ore slurry in the tank, enhance the separation effect.

◆The processing capacity of CTS1840 magnetic separator is over 300 tons per hour.

◆The compound sealing method of multi-groove labyrinth mechanical seal and lip seal ring is used at the end of the roller shaft to avoid the impurities at the end of the shaft from entering and damaging the bearing.

◆The outer part of the aluminum end cover adopts the structure of wide groove and belt hidden stile to avoid the penetration of the ore pulp to the coupling surface of the shaft end parts in production and strengthen the sealing of the equipment.