WHIMS Vertical Ring High Gradient Magnetic Separator

Application

Upgrades

LHGC Advantages Over Traditional Vertical Ring WHIMS

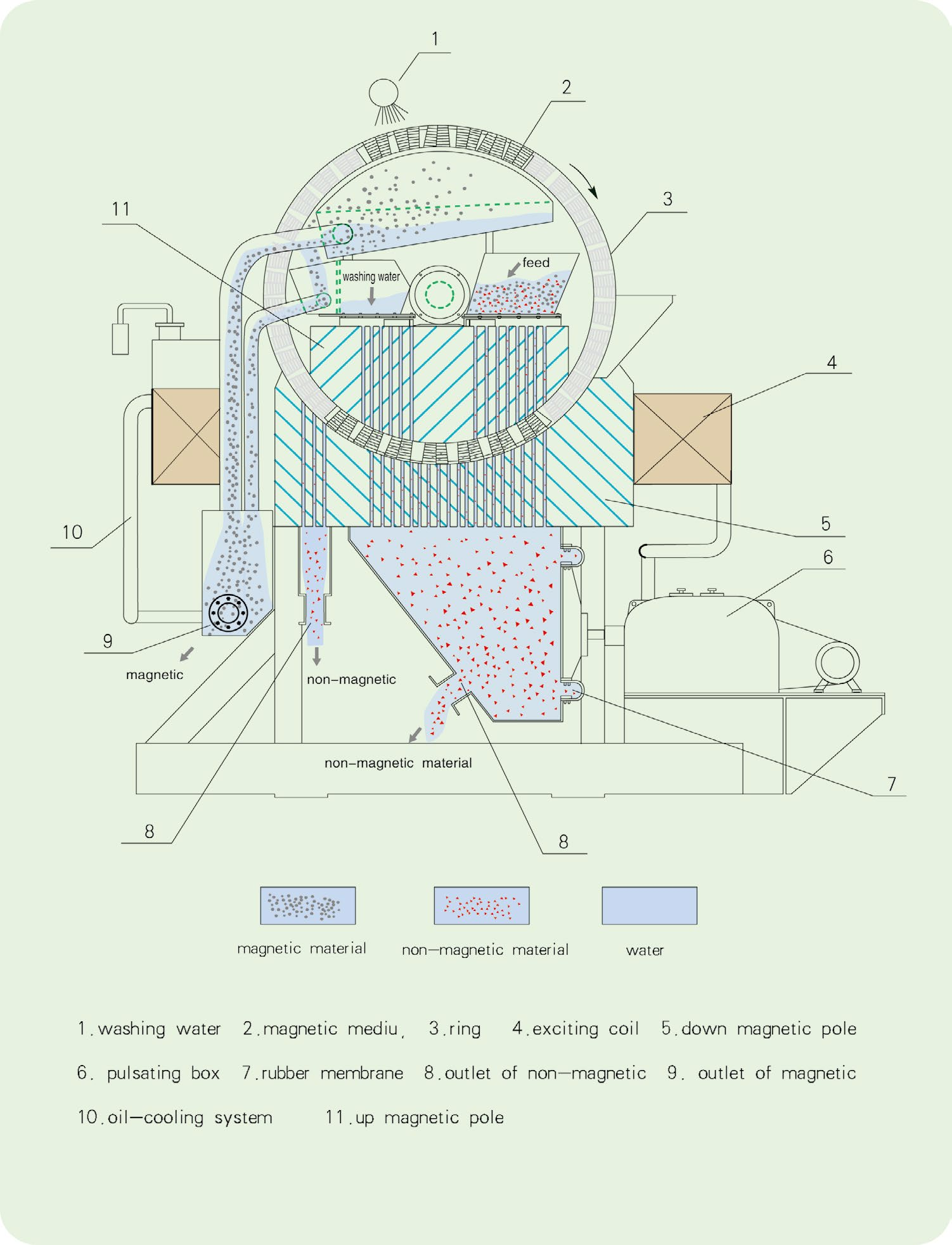

The LHGC oil-water cooling vertical ring high gradient magnetic separator (WHIMS) utilizes the combination of magnetic force, pulsating fluid and gravity to continuously separate magnetic and non magnetic minerals. It possesses the advantages of large processing capacity, high beneficiation

efficiency and recovery rate, small thermal attenuation of magnetic field, thorough discharge, and high degree of intelligence.

The LHGC vertical ring high gradient magnetic separator (WHIMS) is reliable and easy to operate and maintain, and the Internet of Things and Cloud Platform Technology has been applied to realize intelligent automatic operation. To compare with the traditional WHIMS, LHGC adopts a number of new technologies and processes, which effectively improves the operation efficiency, separation accuracy and tailing discard rate, as well as lower maintenance and operating costs.

Technical Features

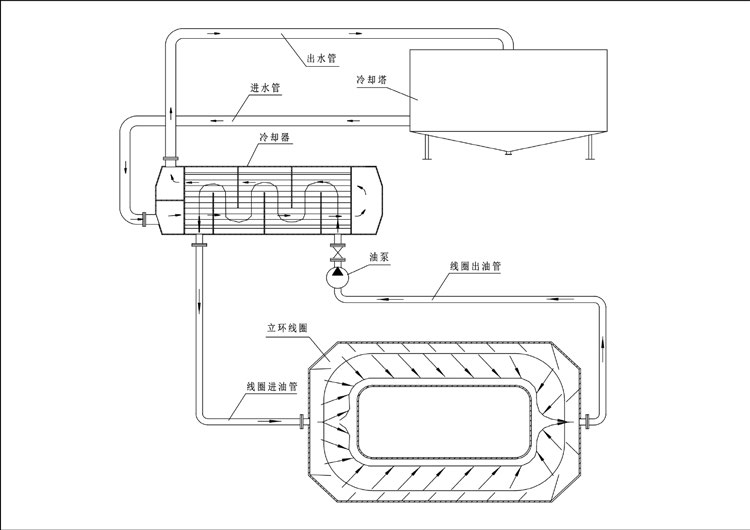

Oil-water Heat Exchange Cooling Technology

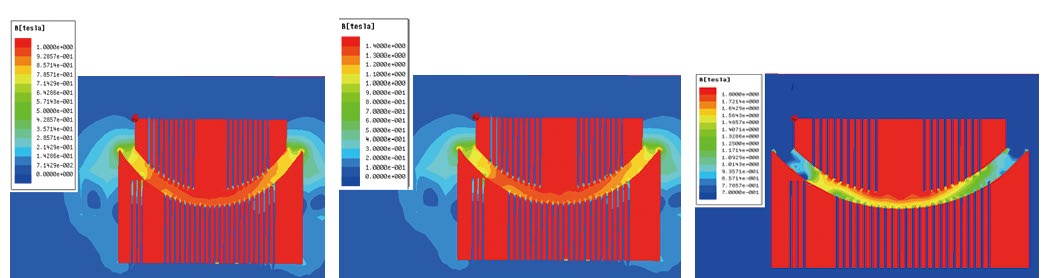

Precise Magnetic Circuit Design

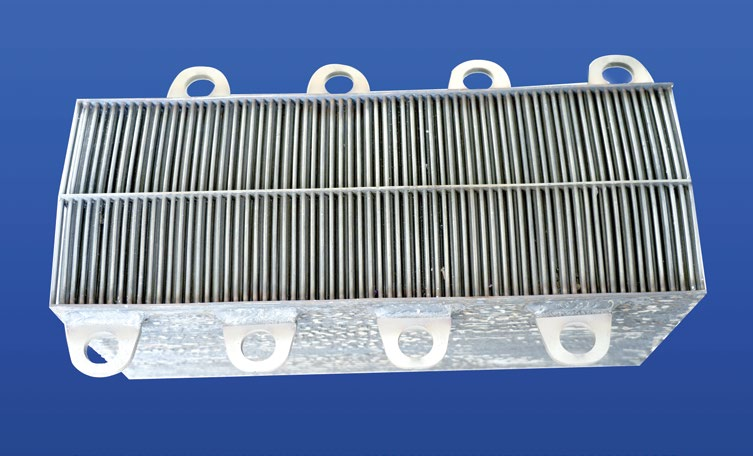

Long-life Integrated Magnetic Matrix

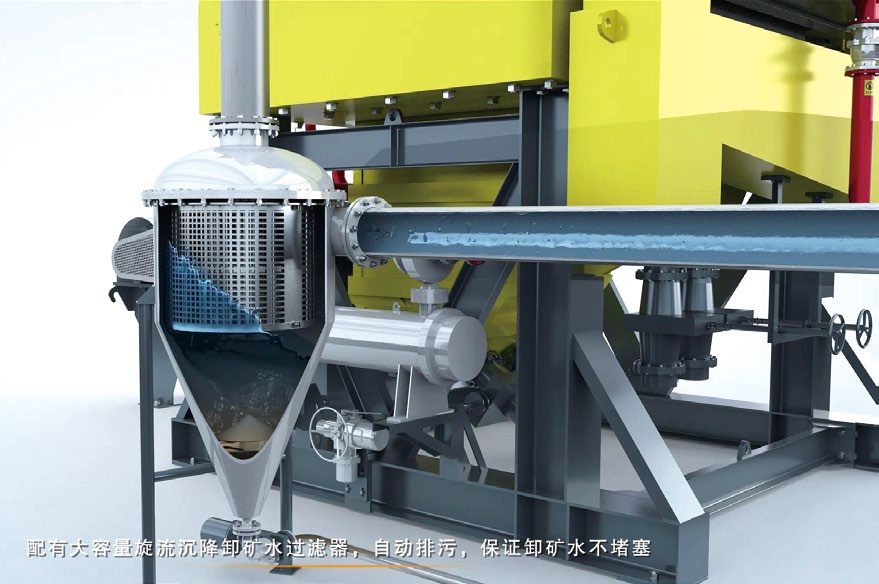

Automatic Cyclone Sedimentation Filtration System

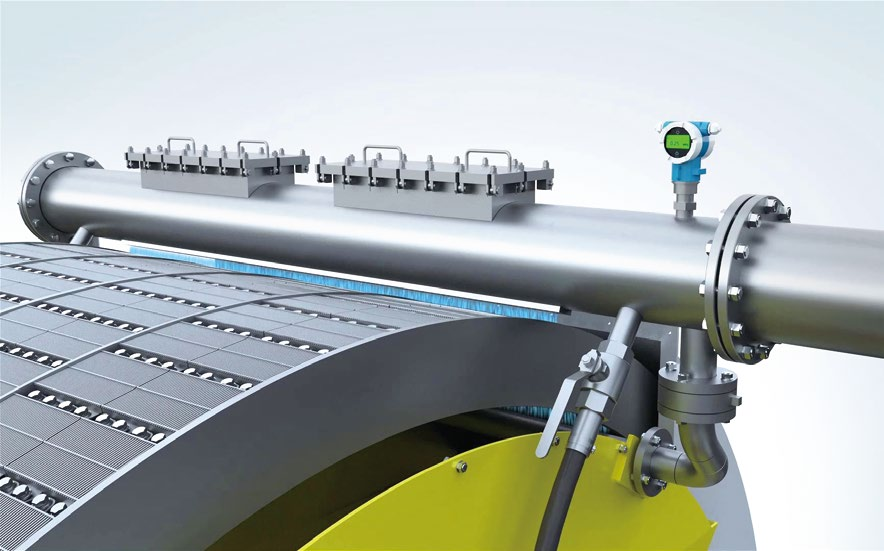

Flushing Water Mineral Discharge System

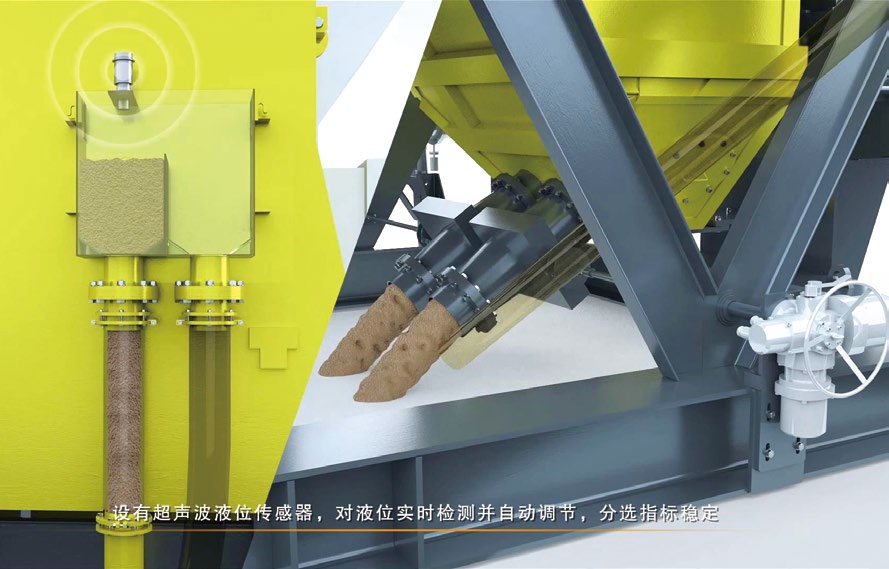

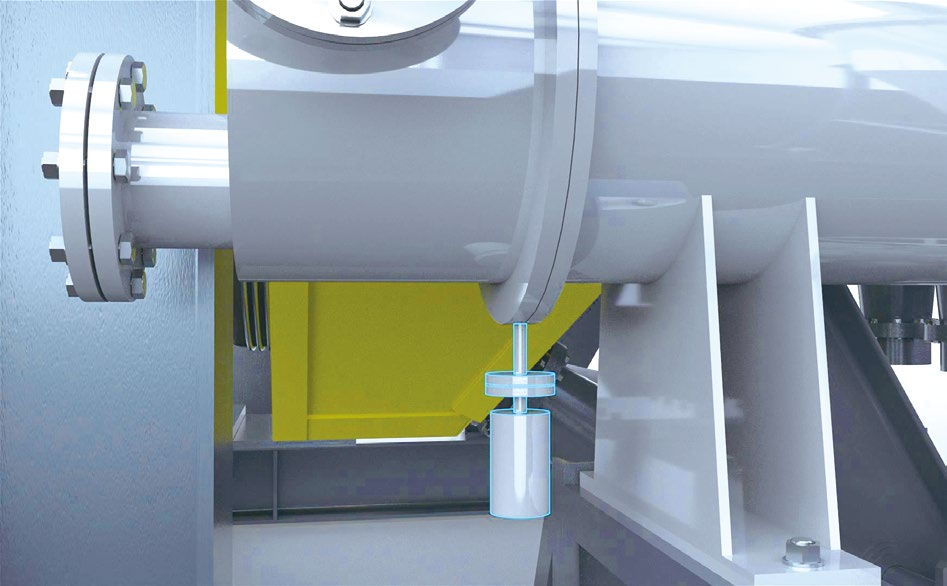

Liquid Level Automatic Control System

The liquid level fluctuation state of the separation chamber is detected in real time by the ultrasonic sensor, and it is linked with the electric actuator,so that the liquid level of the separation chamber always maintains at the best separation state; manual operation is reduced, and the difficulty of manual inspection is lowered; excessive amount of instantaneous slurry is prevented to avoid overflow.

Temperature Alarm Protection System

Coil temperature sensors are provided to detect the working temperature of the coil in real time and feed back the information to the control center. When the coil temperature exceeds the set value, the system will automatically alarm, and the equipment will stop working when the upper limit is reached to ensure the safe operation of the equipment.

Leakage Alarm Device

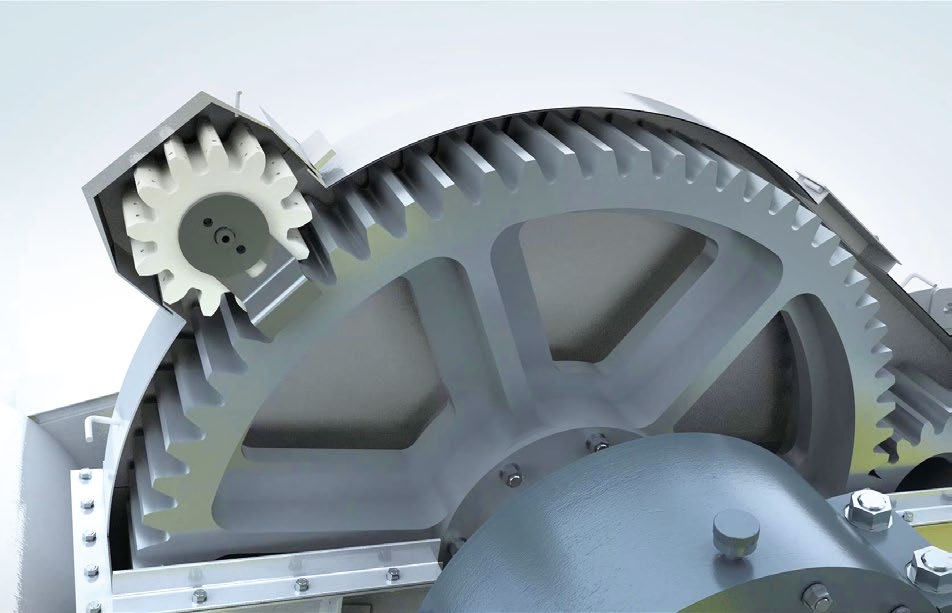

Automatic Lubrication System

The ring drive gear adopts an idle gear automatic lubricating device to ensure that the equipment can realize automatic quantitative lubrication without stopping the operation and improve the operation rate..

Remote Intelligent Service Platform Based on Internet of Things Technology

Operating Principle

Operating Principle

The slurry is introduced to the feeding hopper through the feeding pipe, and enters the magnetic matrix on the rotating ring along the slots in the upper magnetic pole. The magnetic matrix is magnetized, and a high gradient magnetic field is generated on its surface. The magnetic particles

are attracted on the surface of the magnetic matrix, and are brought to the non-magnetic area at the top with the rotation of the ring, and then are flushed into the collection hopper by pressure water flushing. The non-magnetic particles flow into the non-magnetic material collection hopper along the slots in the lower magnetic pole to be discharged.

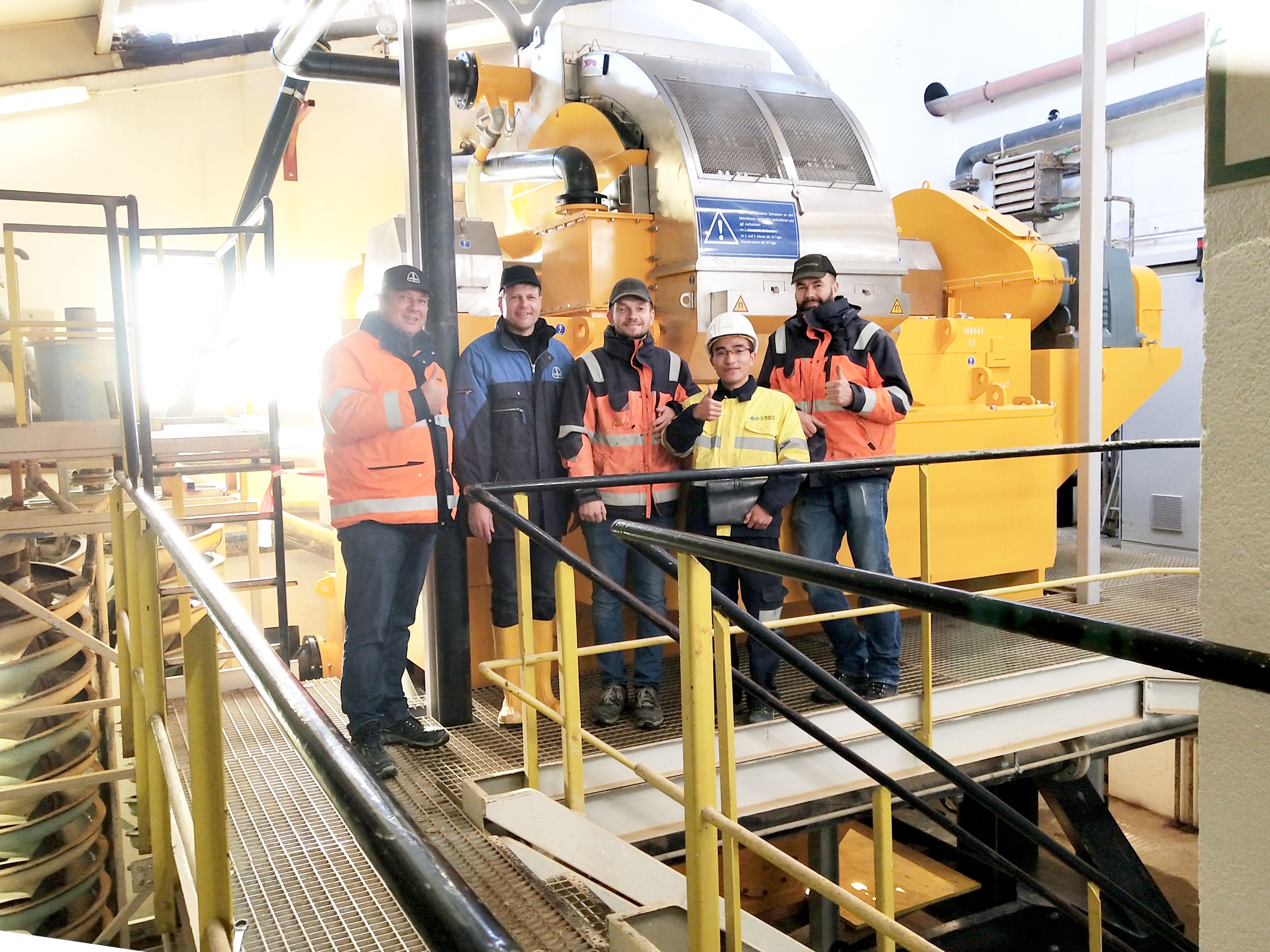

Case Scene