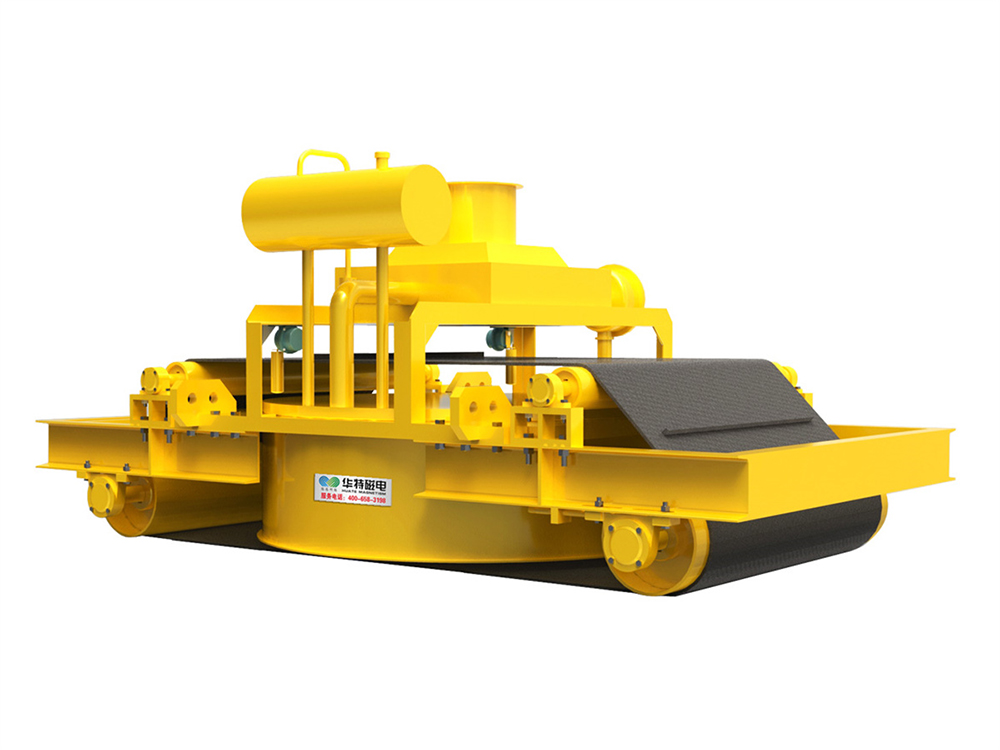

The Global Fifth Generation 1.7T Evaporative Cooling Vertical Ring High Gradient Magnetic Separator

Application:

This product can be used for impurity removal and purification of non-metallic minerals such as quartz、feldspar、nepheline ore and kaolin.

Technical Characteristics:

◆Huate carries out computer simulation magnetic field calculations,reasonable design of magnetic circuit , small loss of magnetic energy, and the magnetic field strength can reach 1.7T。

◆The excitation coil adopts a layered stereo winding structure, which can fully contact the evaporative cooling medium with each part of the coil, greatly improving the heat dissipation capacity of the coil。The structure is advanced and the operation is reliable.

◆Adopting cooling medium of high insulation and appropriate boiling point, which improves the electrical insulation performance of the coil.

◆The coil adopts the thermodynamic phase transition principle for cooling, with high heat dissipation efficiency.Working temperature is not exceeded 48 ℃, and uniform temperature distribution without local hot spots.

◆The evaporative cooling self circulation system has good self-adaptation and self-regulation ability, with small differences in magnetic fields between cold and hot states, and the coil working temperature is not affected by the external environment.

◆The coil works for a long time under low temperature rise, which greatly slows down the aging speed of the coil and prolongs the service life of the magnetic separator. The operation is safe and reliable.

◆The coil adopts a fully sealed structure,,which can adapt to various harsh working environments.。

◆High separating efficiency.It has a wide adaptability to the fluctuations in feed particle size, feed concentration, and feed grade.

◆The rich ore ratio is large and the recovery rate is high.

Technical parameters and main performance indicators:

Model selection method:In principle,the model selection of equipment is subject to the amount of mineral slurry.when separating minerals using this kind of equipment, the slurry concentration has certain influence on the mineral processing index.To get better mineral processing index,please reduce the slurry concentration properly. If the ratio of the magnetic materials in the mineral feed is slightly high, the processing capacity will be limited to the total catching amount of magnetic minerals by magnetic matrix, in the case, the feed concentration should be reduced appropriately.

|

Model

|

LHGC-1500Z |

LHGC-1750Z |

LHGC-2000Z |

LHGC-2500Z |

LHGC-3000Z |

LHGC-3500Z |

| Rated Background Filed (T)

(T) |

≤ 1.7 |

|||||

|

Rated exciting ≤(kW) |

102 |

110 |

120 |

140 |

180 |

200 |

|

Capacity(t/h) |

10 ~ 15 |

15 ~ 25 |

25 ~ 40 |

40 ~ 75 |

75 ~ 125 |

125 ~ 200 |

|

Pulp capacity(m3/h)

|

50 ~ 100 |

70 ~ 150 |

100 ~ 200 |

200 ~ 400 |

350 ~ 650 |

550 ~ 1000 |

|

Exciting current (A) |

0 ~ 380 |

|||||

|

Feed density( %)

|

10 ~ 35 |

|||||

|

Feed size(mm)

|

-1.2 |

|||||

|

Rings rotary speed (r/min)

|

2~4 |

|||||

|

Outer diameter of ringφ (mm)

|

1500 |

1750 |

2000 |

2500 |

3000 |

3500 |

|

Motor power of Ring(kW) |

4 |

7.5 |

11 |

15 |

18.5 |

30 |

|

Exciting voltage(DCV) |

0 ~ 514( Change with current ) |

|||||

|

Water pressure(Mpa) |

0.2 ~ 0.4 |

|||||

|

Water consumption (m3/h) |

20 ~ 30 |

30 ~ 50 |

50 ~ 100 |

100 ~ 150 |

150 ~ 250 |

250 ~ 350 |

|

Weight of largest Part(t) |

16 |

20 |

25 |

28 |

32 |

35 |

|

Outline dimension L× W× H(mm) |

3800×3500×3600 |

4200×3800×4000 |

4942×4686×4728 |

6200×5400×5800 |

7900×7000×7800 |

8500×7600×8500 |

Cooling method of this model can also adopt oil water composite cooling method 。 Remark: Just for reference