TCXJ Electromagnetic Elutriation Separator

TCXJ electromagnetic elutriation and selection machine is a new generation of electromagnetic selection equipment developed by Shandong Huate Company based on the current domestic selection products. The product has undergone major innovation and improvement, solving some shortcomings of ordinary elutriation machines, and has greatly improved comprehensive indi- cators such as improving concentrate grade, controlling magnetic iron grade of tailings, and increasing concentrate recovery rate . This product has applied for domestic invention patents and international invention patents, and passed the provincial and ministerial prod- uct appraisal on May 30, 2015. It is the first domestic and foreign invention and is at the leading international level.

Patent No:ZL201920331098.7 Patent No:ZL201920331079.4 Patent No:ZL201920331116.1 Patent No:ZL201920331119.5 Patent No:ZL201920331865.4

Application

This product is specially designed to purify strong magnetic minerals with a specific magnetization coef- ficient greater than 3000×10-6c m3/g, or to increase the coarse grinding size while ensuring the grade of the original concentrate to improve production efficiency. The concentrate grade can be increased by 2 to 9 %. It can also be used as a concentrator in concentrate concentration operations, and the concentration can reach more than 65%.

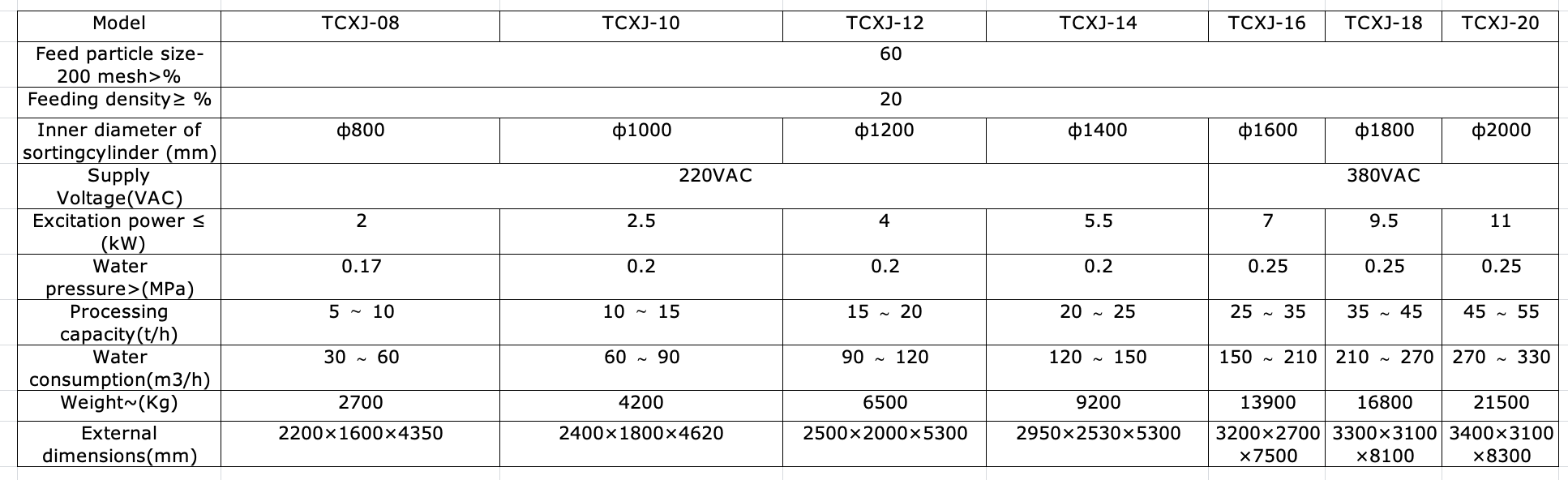

Main Technical Parameters

Note: 1. The on-site water supply pressure when using the equipment shall not be less than the water pressure value required in the technical parameters;

2.Ore samples can be provided when selecting the equipment so that the optimal separation parameters can be determined through magnetic separation experiments.

Main Technical Features

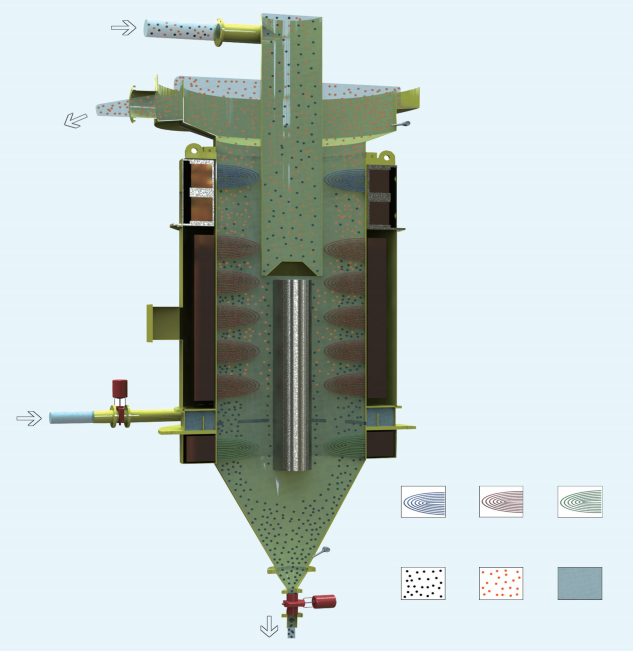

◆ Mineral grades have been greatly improved

The special design of the magnetic circuit and the use of computer finite element analysis make the magnetic field more suitable for the sorting of minerals, release the gangue and poor aggregate mixed in the magnetic chain, and obtain high-grade concentrates.

◆ Low tailings grade and high recovery rate of concentrate

The multi-pole design of the excitation coil for controlling the tailings and the new mode control significantly reduce the total iron and magnetic iron grades of the tailings and significantly increase the concentrate recovery rate.

◆ Even feeding and thorough sorting

Feeding by scattering, combined with the rising water flow, the slurry is quickly and effectively dispersed, scattering evenly, and the elutriation is very thorough.

◆ Isolate non-magnetic and weak magnetic areas, suitable for ultra-fine mineral sorting

The large diameter feeder is used to isolate the non-magnetic and weak magnetic areas, which is suitable for further magnetic separation of higher-grade concentrates to improve the grade or to select finer-grained concentrates, which solves the problem of difficulty in raise the grade of ordinary elutriation machines and The high grade of tailings is diffi- cult to control.

◆ Stable sorting indicators

Adopt isolation transformer plus silicon rectification mode to effectively isolate the impact of the sharp (interference) pulse of the grid power supply on the rectifier module;

the constant current module is adopted, and in the case of fluctuations in the power supply voltage, the output exci- tation current is stable,ensuring the stability of the magnetic field of the elutriation and concentration machine and the stability of the beneficiation indicators.

◆ High level of automation

The Siemens PLC control module is used to detect parameters such as concentrate and tailings concentration, and automatically adjust the water supply valve, concentrate valve and magnetic field strength accurately and quickly to stabilize the working state of the equipment.

◆ Remote control

Siemens PLC programmable controller is adopted to provide intelligent control box data remote transmission and centralized control.

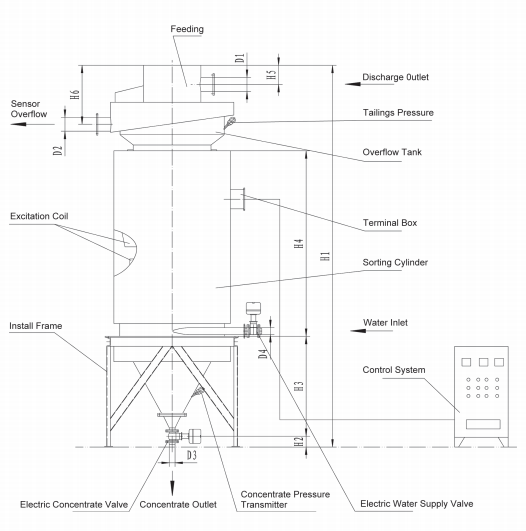

Structural Diagram And Installation Requirements

Structural diagram and installation requirements

1. The inclination angle of the feeding pipe is ≥ 12°; 2. The horizontality deviation of the overflow surface is ≤ 2mm; 3. The water supply pressure is not less than the water pressure value required in the technical parameters.

| No. | Model | Installation dimensions | |||||||||

| H1 | H2 | H3 | H4 | H5 | H6 | D1 | D2 | D3 | D4 | ||

| 1 | TCXJ-08 | 4350 | 580 | 1050 | 1900 | 260 | 750 | Φ219 | Φ219 | Φ89 | Φ108 |

| 2 | TCXJ-10 | 4620 | 580 | 1168 | 2050 | 300 | 880 | Φ219 | Φ219 | Φ89 | Φ108 |

| 3 | TCXJ-12 | 5300 | 430 | 1420 | 2115 | 300 | 925 | Φ219 | Φ219 | Φ89 | Φ108 |

| 4 | TCXJ-14 | 6936 | 570 | 1865 | 2780 | 390 | 1080 | Φ219 | Φ325 | Φ114 | Φ159 |

| 5 | TCXJ-16 | 7535 | 435 | 2105 | 3200 | 463 | 1226 | Φ219 | Φ325 | Φ114 | Φ159 |

| 6 | TCXJ-18 | 8035 | 535 | 2200 | 3530 | 445 | 1135 | Φ219 | Φ410 | Φ140 | Φ159 |

| 7 | TCXJ-20 | 9085 | 535 | 2430 | 4150 | 500 | 1300 | Φ325 | Φ410 | Φ140 | Φ219 |

Schematic Diagram Of The Separation Process

Equipment Using Site