Single Spiral Classifier/Double Spiral Classifier for Metal Beneficiation/Mine Washing Operation

Gaining customer satisfaction is our company’s aim forever. We will make great efforts to develop new and top-quality products, meet your special requirements and provide you with pre-sale, on-sale and after-sale services for Single Spiral Classifier/Double Spiral Classifier for Metal Beneficiation/Mine Washing Operation, Adhering for the enterprise philosophy of ‘customer initially, forge ahead’, we sincerely welcome shoppers from in your house and abroad to cooperate with us.

Gaining customer satisfaction is our company’s aim forever. We will make great efforts to develop new and top-quality products, meet your special requirements and provide you with pre-sale, on-sale and after-sale services for China Classifying Equipment, Classification Equipment, We have advanced production technology, and pursuit innovative in products. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you must be willing to become partners with us. Looking forward to your inquiry.

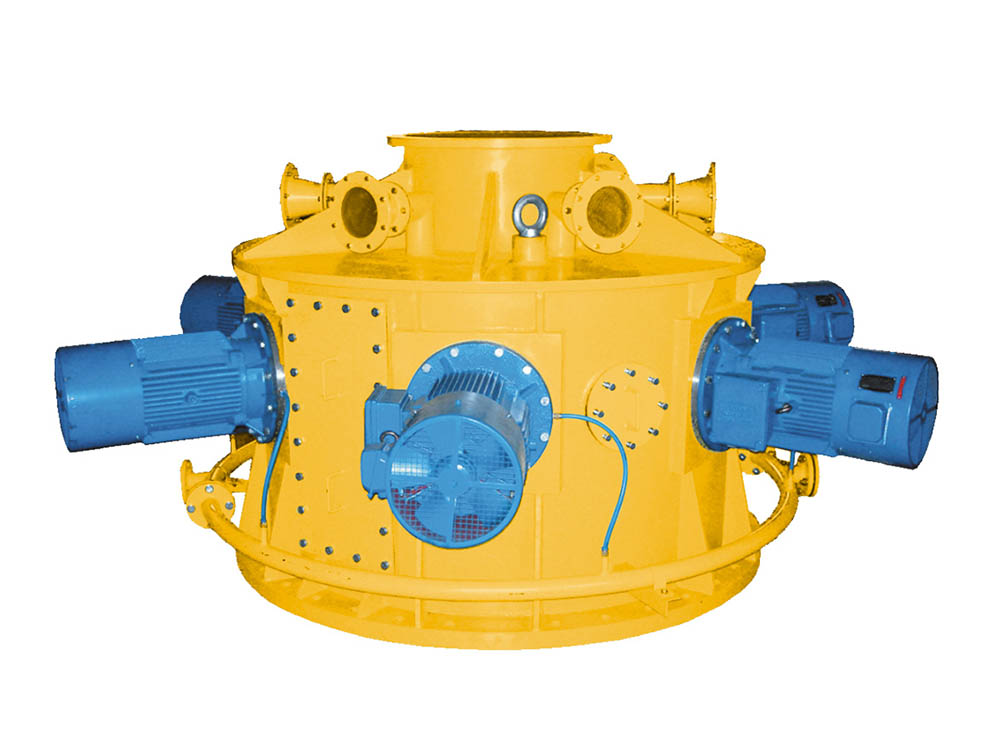

Equipment construction

① Transmission mechanism ② Lifting bucket ③ Spiral ④ Sink ⑤ Nameplate ⑥ Loading port ⑦ Lower support ⑧ Lift

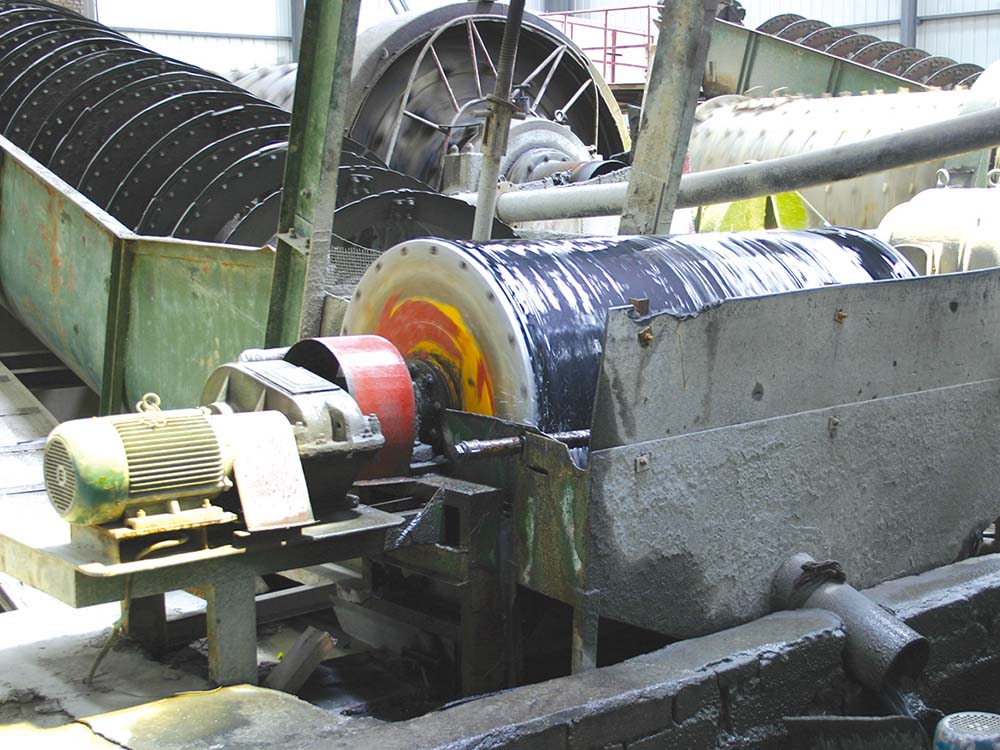

Working principle

The classifier is based on the principle that the size of solid particles is different and the specific gravity is different, so the sedimentation speed in the liquid is different. It is a grading and sedimentation zone of pulp, which rotates at a low spiral speed and stirs the pulp, so that the light and fine particles are suspended above it and left to the overflow side weir to overflow into the next process. The discharge port is used as the sand returning row. Generally, the spiral classifier and the mill form a closed circuit, and the coarse sand is returned to the mill for grinding.

overflow

Overflow weir

Pulp

Inlet

spiral

sink

Sand return

Working principle of spiral classifier

Product technical characteristics

1. The driving methods

(1) Transmission drive: motor + reducer + large gear + small gear

(2) Lifting drive: motor + small gear + large gear

2. Support method

The hollow shaft is welded after being rolled into a seamless steel pipe or a long steel plate. The upper and lower ends of the hollow shaft are welded with journals. The upper end is supported in a rotatable cross-shaped shaft head and the lower end is supported in the lower support. The shaft heads on both sides of the cross-shaped shaft head support are supported on the transmission frame, so that the spiral shaft can be rotated and lifted. The lower bearing support seat is immersed in the slurry for a long time, so it needs a good sealing device. The combination of labyrinth and high-pressure dry oil is used to improve the sealing performance and extend the service life of the bearing.

Applicable Scope:

It is widely used in ore dressing plants and known as split-flow into the factory for ore dressing, ball closed-loop process or gravity for ore grade and fine clay, or used in gravity concentrators to classify ore and fine mud, and metal ore dressing process for ore slurry Carry out particle size classification, desliming, dehydration and other operations in ore washing operations.

Features:

1.The structure is simple, the work is reliable, and the operation is convenient.

2.The spiral shaft is made of integral thick-walled seamless steel pipe with high strength. The spiral shaft is integrally processed with good coaxiality and stable operation.

3.Using wear-resistant white iron spiral blades, long service life and low replacement cost.