Series RCSC Superconducting Iron Separator

Uses and Features:

R C C series low-temperature superconducting magnetic separator uses superconducting magnets to generate a strong magnetic field required for iron removal. The advantage is that in the superconducting state (-268.8°C), there is current without resistance, and the current passes through the superconducting coil to generate a super-strong magnetic field. High magnetic field strength, large magnetic field depth, strong iron absorption ability, light weight, low energy consumption, energy saving and environmental protection, etc., the advantages that ordinary electromagnetic separators cannot match. It is mainly used to remove fine iron impurities contained in the coal seam

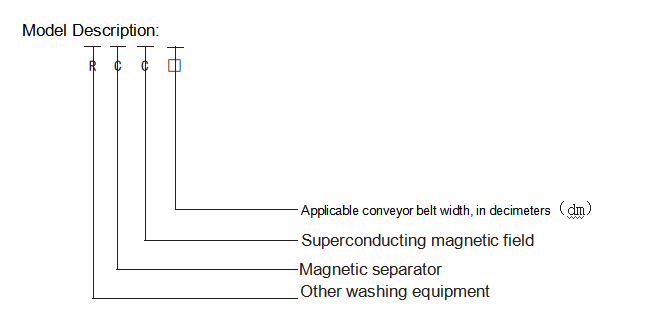

Model Description:

Achievements:

The low-temperature superconducting magnetic separator has passed the provincial and ministerial technical appraisal and product appraisal in November 2008 and June 2010 respectively, and obtained the following three patents:

◆ One invention patent has been confirmed, the patent name is "low temperature superconducting strong magnetic separator"(ZL200710116248.4)。

◆ One utility model patent has been confirmed, and the patent name is "Superconducting Magnetic Separator Suspension Device"(ZL 2007 2 0159191.1)。

◆ One utility model patent has been confirmed, and the patent name is "Flexible protection device for the bottom plate of superconducting Magnetic Separator".(ZL 200820023792.4)。

Equipment structure:

The low-temperature superconducting magnetic separator is mainly composed of the shell and the hanging device, the superconducting magnet part, the refrigeration system and the automatic control system. The superconducting magnet is hung on the shell, and the refrigeration system is used to maintain the temperature of the liquid helium.

The automatic control system can realize remote control and remote fault diagnosis through wireless network. The following figures are the three-dimensional schematic diagram and working pictures of the low-temperature superconducting magnetic separator.

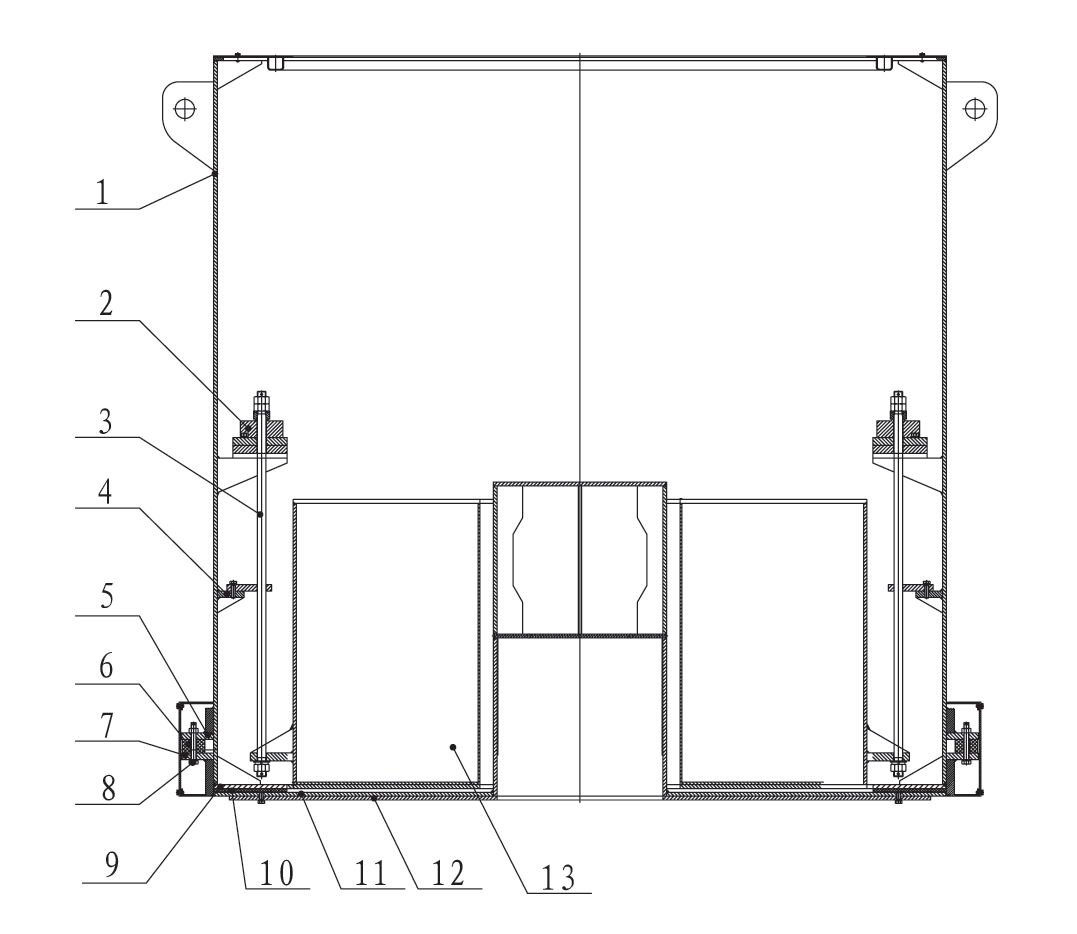

The following figure is a schematic diagram of the shell and hanging device of the low-temperature superconducting magnetic separator

1、shell

2、Pressure Sensor

3、Hanging rod

4、positioning bracket

5、Fixing plate

6、elastomer

7、 movable board

8、connecting bolt

9、Shell bottom plate

10、 flexible rubber

11、 connecting plate

12、High-manganese bottom plate

13、magnet

The magnet 13 of the superconducting magnetic separator is fixed on the shell 1 through the Hanging rod 3, and the upper part of the Hanging rod 3 is equipped with a pressure sensor 2 to detect the force of the superconducting magnetic separator at any time.

When the superconducting magnetic separator is working, the tramp iron impacts on the high-manganese bottom plate 12 of the shell at high speed, forming pressure on the connecting plate 11. At this time, the elastomer 6 is compressed and deformed through the connecting plate 11 to absorb the impact energy. When the impact is large, When the elastomer 6 is compressed to a certain extent, the flexible rubber 10 is compressed to produce deformation and absorb impact energy, effectively ensuring that the shell 1 does not vibrate when the superconducting iron remover is working, thereby ensuring that the superconducting iron remover suspended on the shell 1 the magnet 13 works stably.

working principle :

The following figure is the schematic diagram of the structure of the superconducting magnet. The superconducting coil 6 is immersed in liquid helium 5. The liquid helium provides superconducting low temperature 4.2K when the superconducting coil is working. The liquid helium 5 is encapsulated in the high vacuum 4K Dewar 4. , In order to ensure the lowest heat leakage of the low-temperature Dewar, that is, the 4K Dewar, a 40K heat shield 3 and a 300K Dewar 2 are installed outside it to ensure that the system reaches thermal balance, so that the superconducting iron remover can work reliably and stably. The serial number 1 is a refrigerator .

1、refrigerator

2、300KDewar

3、heat shield

4、4KDewar

5、liquid helium

6、superconducting coil

Due to the extremely high magnetic field intensity generated by the low-temperature superconducting magnetic separator, the huge magnetic field force will cause iron debris to impact the magnet at a very fast speed, which may cause damage to the superconducting magnet. Therefore, the superconducting magnet of the low-temperature superconducting magnetic separator is suspended on the shell through the Suspension Device. The shell is equipped with a national patented product - a flexible hanging device. When iron debris violently impacts the magnet, this device can reliably absorb the impact energy, protect the superconducting magnet from damage, and ensure that the low-temperature superconducting magnetic separator can work well for a long time.

The operation control part of the low-temperature superconducting magnetic separator adopts Chinese and English working interfaces, which is easy to understand, easy to use, easy to maintain, and can realize online transmission of operation records and online monitoring of operation status, realizing remote control and diagnosis,improve the reliability of equipment operation.