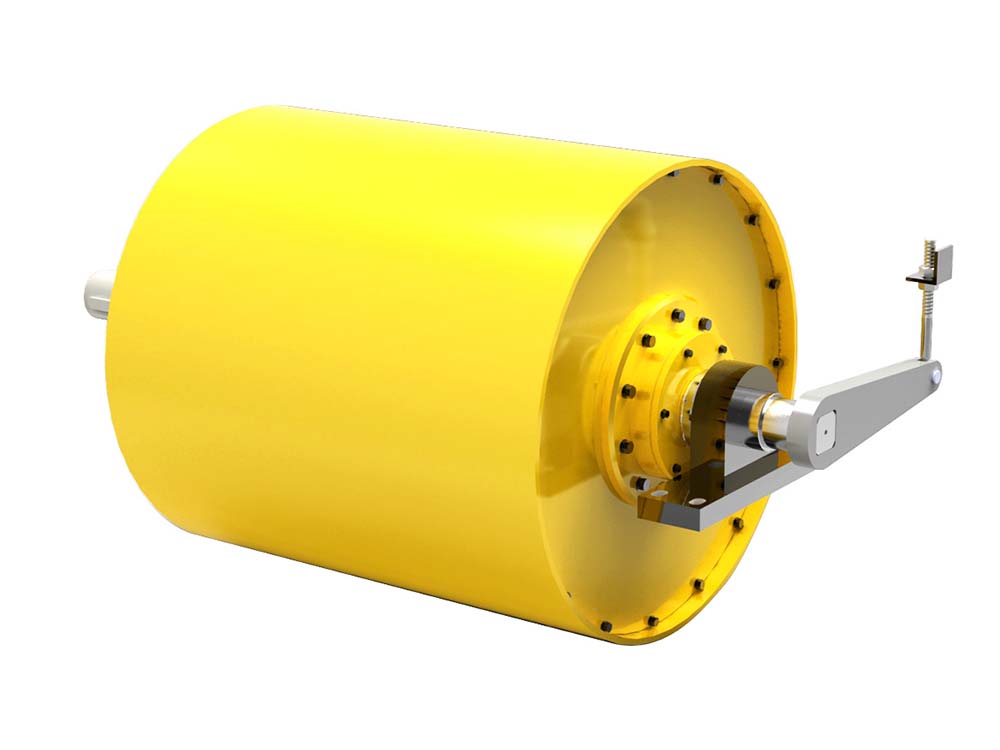

Rare Earth Roller Magnetic Separator

Application:

It can be used to eliminate weakly magnetic oxide from fine particle or coarse power materials and can be widely used for material purification in chemical, refractory material, glass, medical, ceramic and other nonmetallic mineral industries. It can also be used for dry primary separation of hematite and limonite, dry separation of manganese ore.

Features:

Complicate magnetic system, double magnetic pole structure, high magnetic field intensity and large magnetic field gradient.

With the soft magnetic material to induce magnetic force to minimize the loss of magnetic field, and the inducing magnetic force is greatly increased.

Equipped with controllable feeding system.

Automatically wiping off the attracted weakly magnetic oxide and ensure failure-free operation for a long time.

The magnetic induction intensity on the roller surface can reach 2.2T.

Can be designed to single or multi stages according to the customer requirements, easy to disassemble and assemble.

The rotary speed of magnetic roller can be adjusted by frequency converter.

Main Technical Parameters:

|

Model |

Length of magnetic roller mm |

Magnetic field intensity of magnetic roller Gs |

Belt thickness mm |

Processing capacity (t/h) |

Drive motor power (kw) |

|

CFLJ3- Ⅰ |

|

15000-20000 |

0.1-2 |

0.4-1 |

1.5 |

|

CFLJ3- Ⅱ |

|||||

|

CFLJ5- Ⅰ |

500 |

15000-20000 |

0.1-2 |

0.8-2 |

1.5 |

|

CFLJ5- Ⅱ |

|||||

|

CFLJ8- Ⅰ |

800 |

15000-20000 |

0.3-2 |

1.2-3.6 |

2.2 |

|

CFLJ8- Ⅱ |

|||||

|

CFLJ10-Ⅰ |

1000 |

15000-20000 |

0.5-2 |

3-7.2 |

2.2 |

|

CFLJ10-Ⅱ |

|||||

|

CFLJ12-Ⅰ |

1200 |

15000-20000 |

0.5-2 |

4.8-9.6 |

2.2 |

|

CFLJ12-Ⅱ |