-

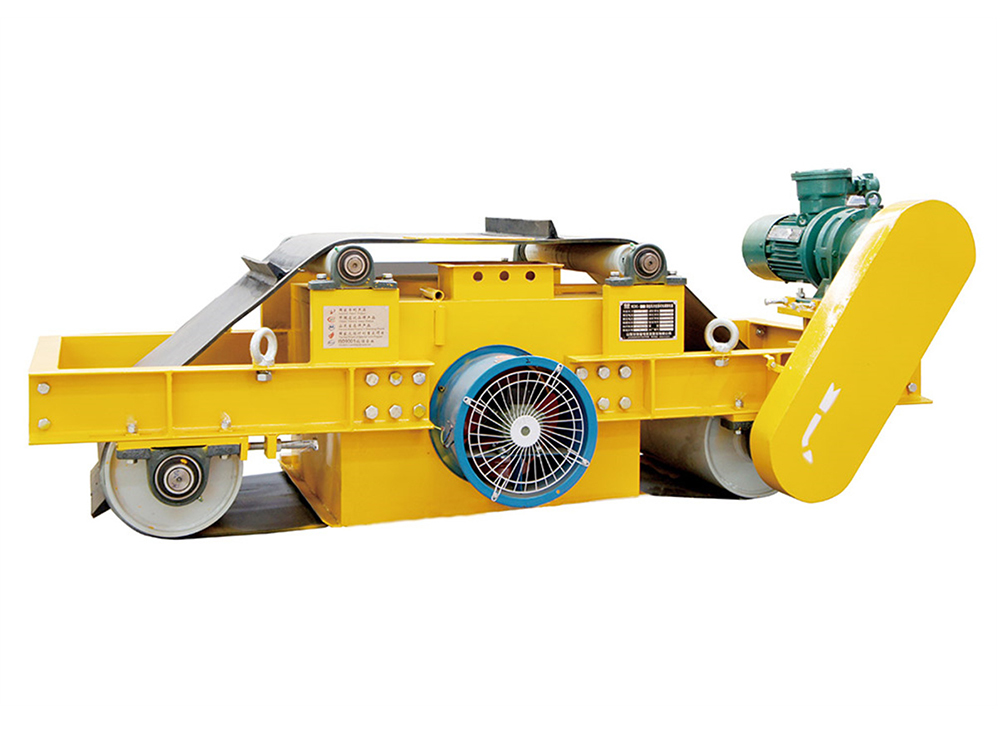

Series RCDC air-cooling self-cleaning electromagnetic separator

For the steel mill,cement plant,power plant and some other department,used for removing iron from slag and protecting the roller ,vertical miller and crusher.It is used in good environment.

-

RCDZ2 Super Evaporative Cooling Self-Cleaning Electromagnetic Separator

For large thermal power plants, coal transportation ports, coal mines, mines, building materials and other places that require high iron removal, and can work normally in harsh environments such as dust, humidity, and severe salt spray corrosion.

-

Series CTY Wet Permanent Magnetic

Series CTY wet permanent magnetic preseparator is designed for the magnetic ore before grinding to preseparating and discarding tailings

-

Series RCDE oil self-cooling electromagnetic separator

For large thermal power plants, coal transportation ports, coal mines, mines, building materials and other places that require high iron removal, and can work normally in harsh environments such as dust, humidity, and severe salt spray corrosion.It is the most common cooling method for electromagnetic field in the world.

-

Series RCSC Superconducting Iron Separator

R C C series low-temperature superconducting magnetic separator uses superconducting magnets to generate a strong magnetic field required for iron removal.

-

Series RCDE oil self-cooling electromagnetic separator

For remove the iron tramp from the various materials on the belt conveyor before crushing and used in harsh environment.

-

Series HSW Pneumatic Mill

HSW series micronizer air jet mill, with cyclone separator, dust collector and draft fan to constitute a grinding system. Compressed air after being dried is injected into grinding chamber quickly by the injection of valves. At connection points of big amount of high-pressure air currents, feed materials are collided, rubbed and sheared repeatedly to powders.

-

Series YCBG Movable Magnetic Separator for Dry Sand

Series YCBG movable magnetic separator for dry sand is medium intensity magnetic separation equipment and can be used to rich magnetic minerals from the powdery ore, marine sand or other lean ore or to eliminate magnetic impurity from powdery materials.

-

RCYA-5Conduit permanent magnetic separator

For remove pollutants such as weak magnetic oxides and rusty scales in liquid and slurry streams, and purify materials in industries such as medicine, chemical papermaking, non-metallic ore, and refractory materials.

-

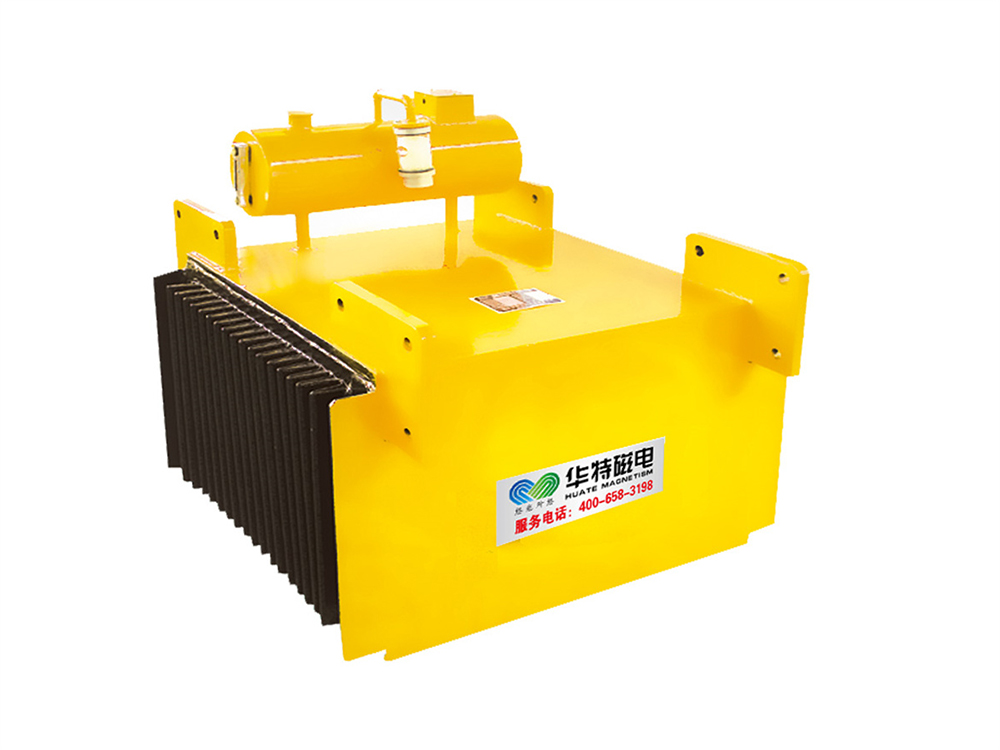

Series RCYB Suspension Permanent Magnetic Iron Separator

Brand: Huate

Product orign: China

Categories: Permanent Magnets

Application: For belt conveyor, vibrating conveyor and feeding chute to eliminate the waste iron.

- 1. High-performance NdFeB magnet for superior iron elimination.

- 2. Easy installation and reliable operation, ideal for harsh environments.

- 3. Zero power consumption.

-

Energy-Saving And Environmental Protection Permanent Magnetic Stirrer(side-installed)

With the unique magnetic circuit design and special treated alnico,it features with robust performance,hightemperature resistance and long service life.

-

Dry Powder Electro Magnetic Iron Remover

It is mainly used to remove magnetic substances in battery materials, ceramics, carbon black, graphite, flame retardants, food, rare earth polishing powder, photovoltaic materials, pigments and other materials.