-

HMB Pulse Dust Collector

Brand: Huate

Product orign: China

Categories: Auxiliary Equipment

Application: Used for air purification by removing dust from the air in various industrial processes. It is designed to attract dust onto the surface of filter components and discharge purified gas into the atmosphere.

- 1. Efficient Dust Collection: Uses a reasonable air current combination to reduce the load on the dust catcher and pulse frequency.

- 2. High-Quality Sealing and Assembly: Features filter bags with special material sealing and a smooth frame, enhancing sealing performance and prolonging bag life.

- 3. High Dust Collection Efficiency: Offers different filter bags tailored to the working environment with a dust collecting efficiency of more than 99.9%.

-

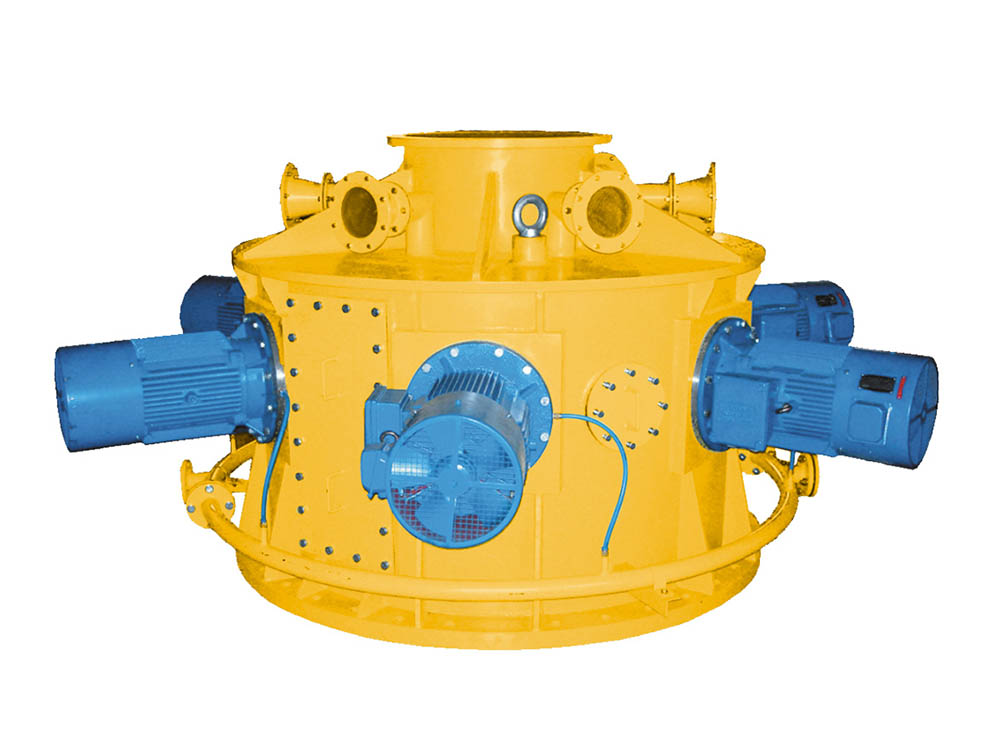

HFW Pneumatic Classifier

Brand: Huate

Product orign: China

Categories: Classification

Application: The classifying device is widely used in chemicals, minerals (non-metallics like calcium carbonate, kaolin, quartz, talc, mica), metallurgy, abrasives, ceramics, fire-proof materials, medicines, pesticides, food, health supplies, and new materials industries.

- 1. Adjustable Granularity: Classifies product sizes to D97: 3~150 micrometers, with easily adjustable granularity levels.

- 2. High Efficiency: Achieves 60%~90% classification efficiency, depending on material and particle consistency.

- 3. User-Friendly and Eco-Friendly: Programmed control system for easy operation, operates under negative pressure with dust emissions below 40mg/m³ and noise levels under 75dB (A).

-

HF Pneumatic Classifier

Brand: Huate

Product orign: China

Categories: Classification

Application: This classifying device is suitable for industrial fields requiring precise particle classification, especially in applications where strict control of particle size is essential.

- 1. High Precision Classification: The specially designed classifying structure and high classification precision can strictly block large particles, ensuring product fineness.

- 2. Adjustability: The rotary speed of the classifying wheel and the air inlet volume can be adjusted to obtain the desired product, providing flexibility to meet different production requirements.

- 3. Efficient and Stable Performance: The single low-speed vertical rotor design ensures a stable flow field, offering high efficiency and robust performance.

-

Dry Quartz-Processing Equipment

Brand: Huate

Product orign: China

Categories: Grinding

Application: Specially designed for the quartz-making field in the glass industry.

- 1. Pollution-Free Production: Silica lining prevents iron contamination during the sand production process.

- 2. Durable and Stable: High-quality alloy steel components ensure wear resistance and minimal deformation.

- 3. High Efficiency: Equipped with multiple grading screens and a high-efficiency Pulse Dust Collector for clean and efficient production.

-

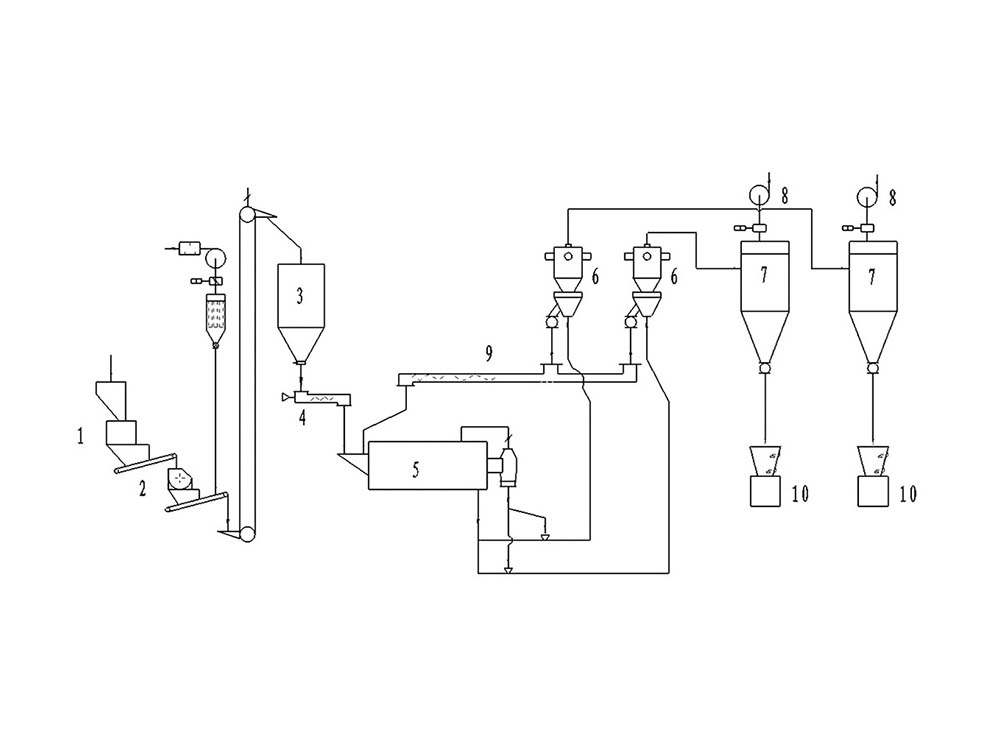

Process flow of Quartz sand Production Line

Process flow of Quartz sand Production Line

-

Processing Line for Battery Material

Application: The processing line is mainly used in the crushing classification of battery positive and negative electrode material. It can also be applied in Mosh’s hardness below 4 material of the chemical, foodstuff, non-mineral industry and so on.

-

Series HSW Horizontal Jet Mill

HSW series micronizer air jet mill, with cyclone separator, dust collector and draft fan to constitute a grinding system. Compressed air after being dried is injected into grinding chamber quickly by the injection of valves. At connection points of big amount of high-pressure air currents, feed materials are collided, rubbed and sheared repeatedly to powders. The grinded materials go into classifying chamber with uprising air flow, under the condition of lashing forces of draught. Under strong centrifugal forces of high-speed rotating turbo wheels, coarse and fine materials are separated. Fine materials in line with size requirements go into cyclone separator and dust collector through classifying wheels, while coarse materials fall down to grinding chamber to be grinded continuously.

-

Series HS Pneumatic Jet Mill

Series HS pneumatic mill is a device adopting high-speed airflow to fine dry material.

-

Series HPD Pneumatic Jet Mill

The materials are brought into crushing chamber by compressed air through material-feed jet. The compressed air distributes in several air jets uniformly to release transonic air current, which forms strong eddy flow in the mill chamber to force the particle in the material to collide and rub.

-

Series HJ Mechanical Super Fine Pulverizer

The equipment is a new-type of grinder. It has a dynamic disc and static disc. The material is grinded with the impact, friction and cutting forces on the static disc by the high rotary speed of the dynamic disc. Under the negative pressure, the qualified powder enters into classifying zone and is gathered by the collector while the coarse material returns for further grinding.

-

Ball Mill &Horizontal Classifier Production Line

The whole process of the technology ensures that the emission of dust is lower than 40 mg / m3 and 20 mg / m3 after production, by adopting the combination of dust collector, draft fan and pneumatic conveying system, the strict control of every dust concentration point, and the use of high-quality filter material. The equipment can prevent dust leak and make the whole technological process negative and clean.

-

Ball Mill & Vertical Classifier Production Line

Application

Soft material: calcite, marble, limestone, barite, gypsum, slag etc.

Hard material: quartz, felspa, carborundum, corundum, fine cement etc.