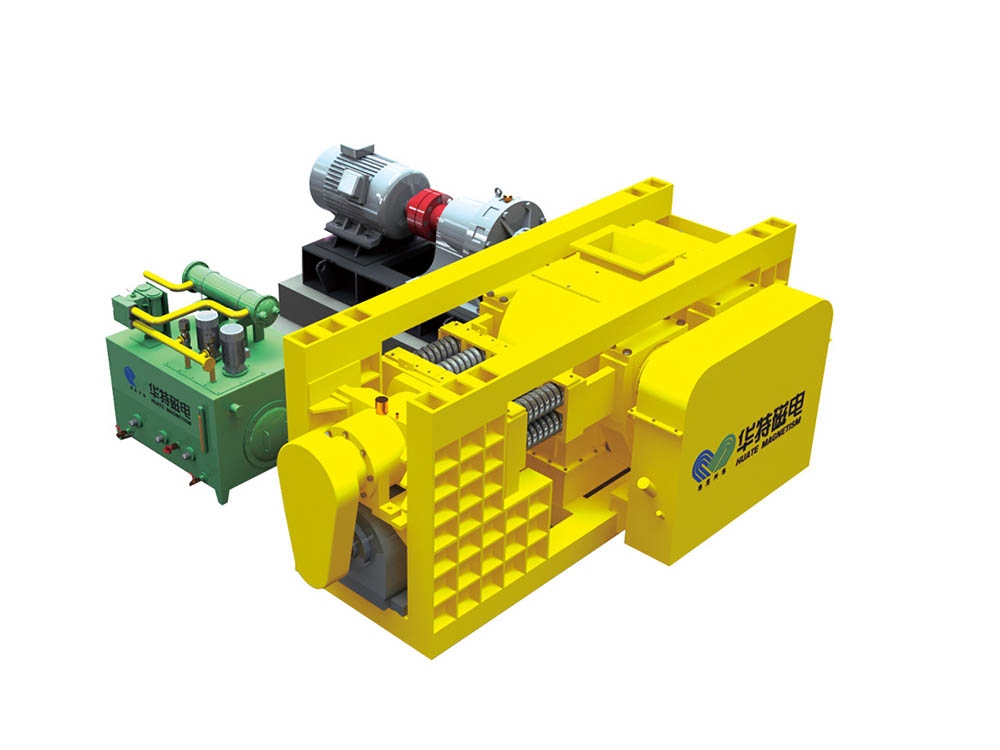

Popular Design for China Auto-Discharge Self Cleaning Belt Type Magnetic Separator

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for Popular Design for China Auto-Discharge Self Cleaning Belt Type Magnetic Separator, Make sure you sense absolutely no cost to speak to us for organization. nd we imagine we’ll share the most effective trading practical experience with all our merchants.

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for China Belt Magnetic Separator, Overband Magnetic Separator, We’ve established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Make sure you feel free to contact us for more details.

Machine features

Thoroughly solve the three major problems of heat dissipation, suction and environmental adaptation in general separator.

Technology features

◆ The excitation coil adopts a layered winding structure, make the evaporative cooling medium fully contact with the coil, and improve the heat dissipation of the coil.

◆ The low rising working temperature, about 40C, slow down the aging speed of the coil and increases the service life of the separator.

◆ The high insulation and suitable boiling point cooling medium,improve the electrical insulation performance of the coil and ensures safe and reliable operation.

◆ Using the principle of thermodynamic phase change to cool the coil to ensure the low temperature and uniform temperature distribution of the electromagnetic separator.

◆ Evaporative cooling self-circulation system has small self-adaptation and self-regulation ability. The difference between suction in cold and hot is small, and the temperature does not change with the change of external environment.

◆Self-cleaning, easy maintenance, drum-shape structure, automatic belt-off-position correct,fully sealed bearing seat, and a labyrinth seal structure, used in large dust applications. It is suitable for coal transportation ports, large thermal power plants, coal mines, mines, building materials and other places with particularly high requirements for iron removal. It can work normally in harsh environments such as dust, humidity, and severe seaside salt spray corrosion.Thoroughly solve the three major problems of heat dissipation, suction and adaptation to the environment of ordinary iron separators.

1.The excitation coil adopts a layered winding structure, which can make the evaporative cooling medium fully compatible with the line.The coil contact greatly improves the heat dissipation level of the coil.

2. The working temperature rise of the coil is low, only about 40ºC, which greatly slows down the aging speed of the coil and improves the service life of the iron remover.

3. The application of a cooling medium with high insulation and suitable boiling point improves the electrical insulation performance of the coil and ensures safe and reliable operation.

4.The coil is cooled by the principle of thermodynamic phase change to ensure that the operating temperature of the electromagnetic separator is low and the temperature distribution is uniform.

5.The evaporative cooling self-circulation system has a small difference in suction between cold and hot due to its good self-adaptation and self-adjustment capabilities, and the temperature does not change with changes in the external environment.

6.Automatic unloading of iron, easy maintenance, drum-shaped structure, automatic belt correction function, special fully sealed bearing seat, labyrinth seal structure, can adapt to dusty applications on site.

Shandong Huate magnet technology co.,ltd is specializing in manufacturing cryogenic superconducting magnetic separation equipment,magnetic iron separator ,magnetic stirrer ,ultra-fine grinding and classifying equipment,mining compete set equipment,etc.medical magnetic resonance imaging (MRI) superconducting magnet.Our service scope involves coal,mine,electricity,building material,metallurgy,non-ferrous metal,environmental protection,medical and so on more than 10 fields.With more than 20,000 customers ,our equipment are exported to USA,Europe,Australia and many other countries.

We are committed to building long-term customer cooperation relationship.