Ordinary Discount China Ce Certificated Amino Pop Conc Powder Ball Mill

While using the “Client-Oriented” company philosophy, a demanding high-quality management method, innovative producing products and also a sturdy R&D workforce, we always deliver premium quality merchandise, superb solutions and aggressive selling prices for Ordinary Discount China Ce Certificated Amino Pop Conc Powder Ball Mill, By means of our hard get the job done, we have usually been to the forefront of clean technology products innovation. We’ve been a eco-friendly partner you can rely on. Get in touch with us today for more details!

While using the “Client-Oriented” company philosophy, a demanding high-quality management method, innovative producing products and also a sturdy R&D workforce, we always deliver premium quality merchandise, superb solutions and aggressive selling prices for China Amino Ball Mill, Pulverizer, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

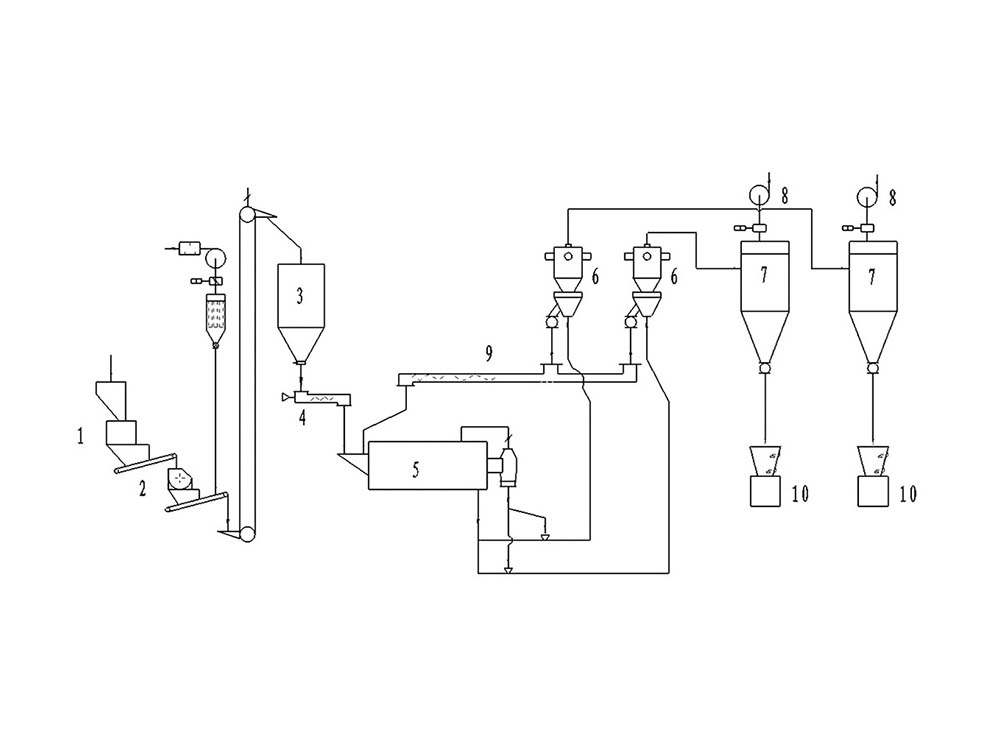

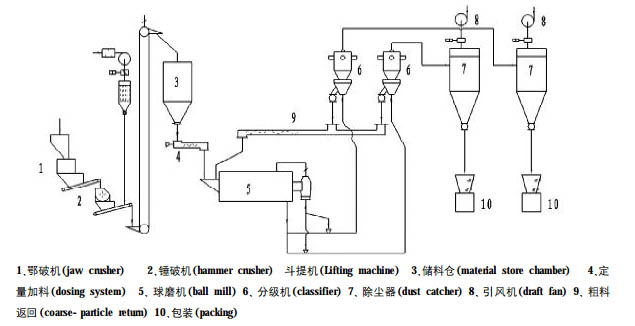

Application

◆Soft material: calcite, marble, limestone, barite, gypsum, slag etc.

◆Hard material: quartz, felspa, carborundum, corundum, fine cement etc.

Characteristics

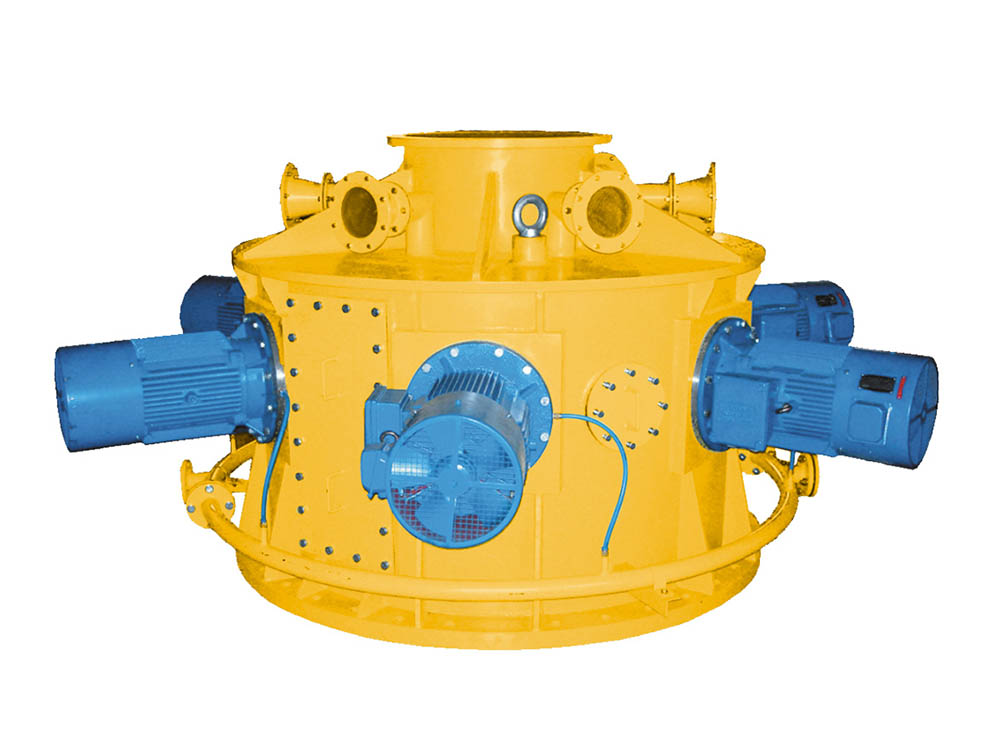

◆Designed to the standards of ultrafine mineral manufacturing.

◆Optimized length-to-diameter factor of ball mill

◆Grid plate at the end of the ball mill discharges powder fluently, no dilating and no necessary to cool the tube

◆Grinding medium chosen according to customers’product, high filling rate and efficiency

◆Perfect match between drive station and energy consumption of grinding, energy saving to the fullest extent possible.

◆Forming a closed system with classifier, with negative pressure transport, without powder pollution.

Note: All of the parameters above are according to 1250 mesh GCC.

As different material from different places, the parameter is just for your reference.

Application Site