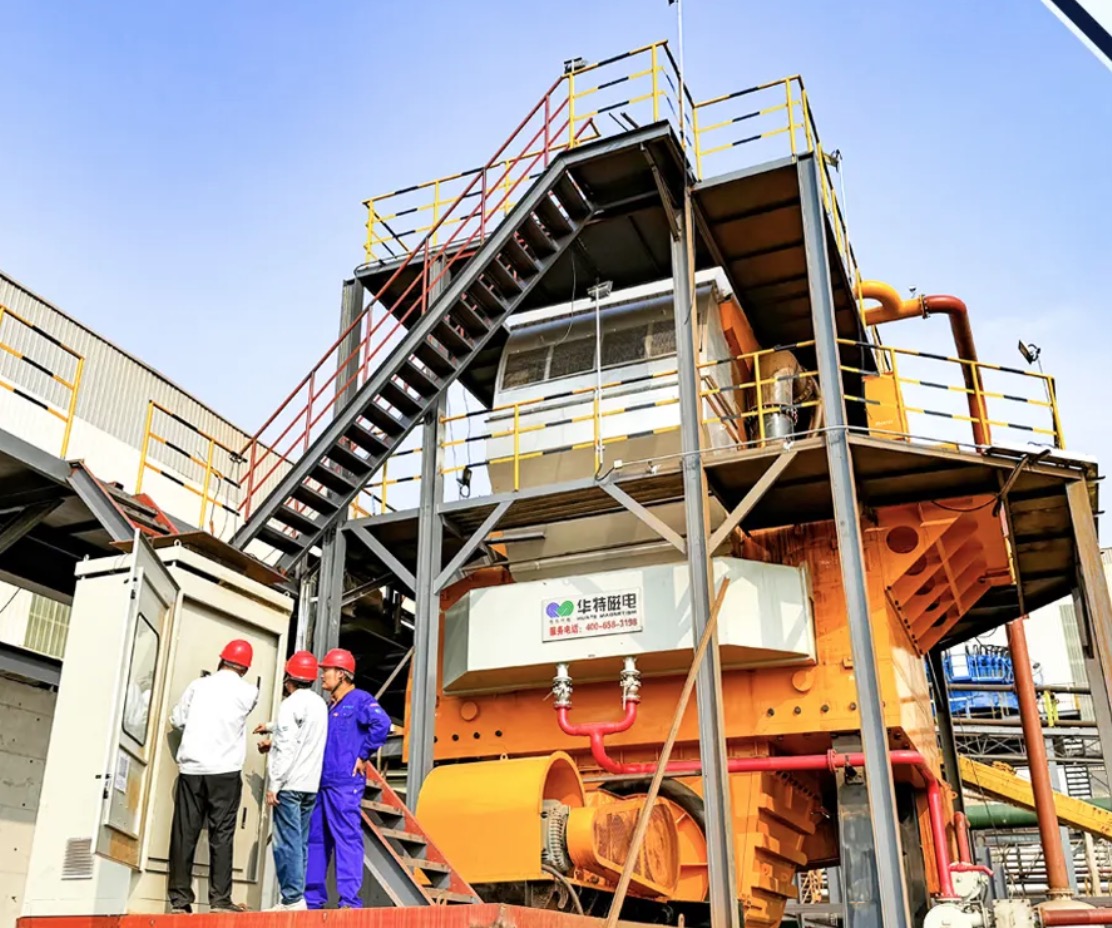

The World’s First and Largest 6-meter Intelligent Vertical Ring High Gradient Magnetic Separator (LHGC-WHIMS) Puts Into Operation in Hebei and Shandong.

This breakthrough marks a significant advancement in both China’s and the global high-end magnetic separation technology for mineral processing.

Giant Equipment, Exceptional Efficiency

The LHGC-6000 intelligent vertical ring WHIMS has a 6m diameter of its core ring component, 11.8 m equipment height and with a background field strength of <=1.8T (Tesla).Taking Anshan low-grade hematite as an example, the dry ore processing capacity reaches 1300 tons per hour, while non-metallic minerals like quartz sand can be processed at a rate of 800 tons per hour—eight times the processing capacity of a 3-meter high-gradient magnetic separator.

Energy Conservation, Cost Optimization

The energy consumption per ton of ore processed by the giant 6-meter intelligent high-gradient magnetic separator has been reduced by over 60%, greatly lowering operating costs. Additionally, due to its compact footprint and simplified process layout, compared to traditional equipment, it can save more than 30% in engineering investments, perfectly meeting the needs of large-scale mining enterprises with annual outputs in the tens of millions of tons.

Intelligent Control, Leading the Future

The 6-meter intelligent high-gradient magnetic separator integrates advanced multi-point automation control technologies, including automatic adjustment of the sorting chamber’s liquid level, temperature control for the cooling system, real-time monitoring and adjustment of discharge water pressure, and automatic lubrication. This enables intelligent operation of the equipment, which not only enhances production efficiency but also ensures long-term stable operation.

Technological Breakthroughs and Patent Achievements

During the technological innovation for the “Vertical Ring High Gradient Magnetic Separator”, Huate achieved breakthroughs in modular combination techniques for oversized components, such as the set-type magnetic poles and staged-section rotating rings. The coils adopt a three-dimensional winding structure, with fully enclosed large-flow external cooling, demonstrating strong R&D capabilities. To date, Huate has applied for and been granted 36 domestic and international patents, including both invention patents and utility model patents.

Brand Journey, Global Leadership

For years, Huate has adhered to the entrepreneurial philosophy of “innovation without boundaries,” closely following global cutting-edge magnetic and electrical technology. Huate has made breakthroughs in a number of key core technologies with independent intellectual property rights, as well as “bottleneck” technologies. As of now, our high-gradient magnetic separators have been widely used in over 2,200 units worldwide, generating a total social benefit exceeding 70 billion RMB. Huate has thus paved the way for the brand development of China’s high-tech magnetic and electrical enterprises, securing its place at the forefront of global magnetic technology.

The successful production and application of the 6-meter Intelligent Vertical Ring High Gradient Magnetic Separator (LHGC-WHIMS) not only serves as further proof of Huate’s technological innovation capabilities but also marks a significant step in the global mining industry’s move towards smart and efficient development.

In the future, Huate will fully leverage its technological advantages in mineral processing, continue to break through bottleneck technologies, and lead the development of humanized, compact, intelligent, and green low-carbon mining equipment. Huate aims to enhance Chinese manufacturing influence and leadership in the global market, providing reliable key technologies and equipment for the development and utilization of the country’s strategic mineral resources.

Post time: Dec-10-2024