Testing of common elements in iron ore

With the continuous development of the economy and the continuous improvement of social status, steel materials have become an indispensable resource for national development. The smelting of steel materials in the steel industry is the main stage of rational utilization of materials. All aspects of people's lives require attention to structural materials and some functional materials. The development of various industries in our country, such as transportation, electricity and many other industries, are paying attention to steel materials. With the continuous development of our country's economy, the demand for steel materials in the domestic market continues to increase. However, the content of some elements in steel has exceeded the national standard content in the programmer. Therefore, in international trade, the demand for iron ore The detection of various elements has become a very important link. Therefore, using a fast and safe inspection method is a common goal for iron ore inspection personnel.

Current status of testing of common elements in iron ore in my country

The most common iron ore testing laboratories in my country use the reduction method of titanium trichloride to detect the elemental iron content in iron ore. This detection method is called chemical method. This chemical method not only detects elements in iron ore but also uses wavelength dispersive X-ray fluorescence spectroscopy to determine the content of silicon, calcium, manganese and other elements in iron ore. The detection method for several elements is called X-ray fluorescence spectrometry detection method. While detecting various elements in iron ore, the full iron content can also be detected. The advantage of this is that in each detection, two iron content data will be obtained, and the two data are very different in data values. Small, but there are also a small number of differences that are very different. The testing method used in the laboratory should be selected according to the different iron ores, because my country uses chemical methods as a common method, and it plays a central role. A big reason is that The selection is based on the structural characteristics of iron ore in my country. The inspection method is selected according to the different structural characteristics of iron ore to be reasonable and scientific. The distribution of iron ore in China is relatively scattered and the storage area is relatively small. The quality is unstable in different places. There are many differences from those abroad. Foreign iron ore is distributed very concentratedly, has a relatively large storage area, and is of very stable quality compared to our country.

With the continuous development of our economy, the technological development of testing laboratories and the continuous expansion of their publicity services have greatly increased the business volume of laboratory testing elements, so that they have sufficient resources to conduct testing. Our country's laboratories need to test several Thousands of batches of business have been added to the detection data. With the continuous increase in the detection of iron ore elements in our country, the samples must be dried during chemical testing. Each drying process requires manual operation. During the entire process, on the one hand, operations The staff are fully committed to perfecting every link. If this happens for a long time, the personnel's body will not get a good rest and will be in a state of overload, which is likely to lead to a decline in the quality of the work. In terms of its detection, it is very likely that some periodic problems will occur. On the other hand, during the operation process, the consumption of water, electricity and the use of some chemicals have greatly affected and damaged the environment within a certain range. At the same time, the exhaust gas and waste water cannot be well treated. So It is very important to improve detection efficiency to make detection data more accurate. Our country's laboratories have been testing iron ore for many years, and have mastered a lot of testing experience and a large amount of testing data. These data are based on chemical methods and X-ray fluorescence spectroscopy. By analyzing these data, we can find X-ray fluorescence. Spectroscopy is a new method that can replace chemical methods. The advantage of this is that it can save a lot of manpower and financial resources and reduce environmental pollution.

01

X-fluorescence method inspection principle and inspection steps

The principle of X-ray fluorescence spectroscopy is to first use anhydrous lithium tetraborate as a flux, lithium nitrate as an oxidant, and potassium bromide as a release agent to prepare a sample piece, and then measure the X-ray fluorescence spectrum intensity value in the iron element to make it A quantitative relationship is formed between element content. Calculate the content of iron in iron ore.

The reagents and instruments used in the X-ray fluorescence spectroscopy experiment are distilled water, hydrochloric acid, anhydrous lithium tetraborate, lithium nitrate, potassium bromide and gases. The instrument used is X-ray fluorescence spectrometer.

The main detection steps of X-ray fluorescence detection:

■ Anhydrous lithium tetraborate is used as a flux, lithium carbonate is used as an oxidant, and potassium bromide is used as a release agent. Several solutions are mixed with each other to allow full reaction.

■ Before testing iron ore, iron ore samples need to be weighed, melted, and cast to make standard test pieces.

■ After the iron ore sample is prepared, it is analyzed using X-ray fluorescence spectroscopy.

■ To process the generated data, generally take a standard sample piece and place the sample piece on the X-ray fluorescence spectrometer. Repeat the test multiple times, and then record the data. Making a standard specimen consumes only a certain amount of anhydrous lithium tetraborate, lithium nitrate, and potassium bromide.

02

Chemical testing principles and testing procedures

The principle of chemical detection is that the standard sample is decomposed or acidified with acid, and the iron element is fully reduced with stannous chloride. The last small part of the remaining iron is reduced with titanium trichloride. The remaining reducing agent is fully oxidized with potassium dichromate solution and the reduced iron element is titrated. Finally, the potassium dichromate solution consumed by the standard sample is used. Calculate the total iron content in the sample.

The reagents and materials used in the detection are: reagents, hydrochloric acid, sulfuric acid, phosphoric acid, boric acid, hydrofluoric acid, potassium pyrosulfate, sodium hydroxide, sodium peroxide, etc. Instruments and equipment: Corundum crucible, platinum crucible, burette, balance, etc.

The main detection steps of chemical detection:

■ Use several solutions including stannous chloride solution, titanium trichloride, and potassium dichromate standard solution to blend with each other. Allow the reaction to proceed fully.

■ Use acid or alkali to fully decompose the standard sample.

■ Titrate the decomposed standard sample with potassium dichromate solution.

■ To process the generated data, two standard sample solutions and one blank solution need to be prepared during the experiment.

Conclusion

In many countries, the most commonly used method for detecting elements in iron ore is X-ray fluorescence spectroscopy. The detection of this method mainly focuses on the analysis of the method principle, and continuous improvement of existing methods to meet the requirements of accurate detection results. When conducting evaluation, generally a very small amount of standard solution is used to conduct a reasonable evaluation of the detection method. assessment. Since the iron ore in the experiment is very different from the iron ore in the standard sample in terms of shape, chemical composition, etc., the X-ray fluorescence spectrometry method is not very precise in the inspection process. The accuracy is achieved by sorting out a large amount of data accumulated during the iron ore detection by chemical methods and X-ray fluorescence spectrometry in the experiment, and then statistically analyzing the data, and comparing the differences between the two detection methods through analysis. Finding the correlation between the two can reduce the human and financial resources invested in inspection to a great extent. It can also greatly reduce environmental pollution, make people's lives more comfortable, and generate more economic benefits for my country's steel industry.

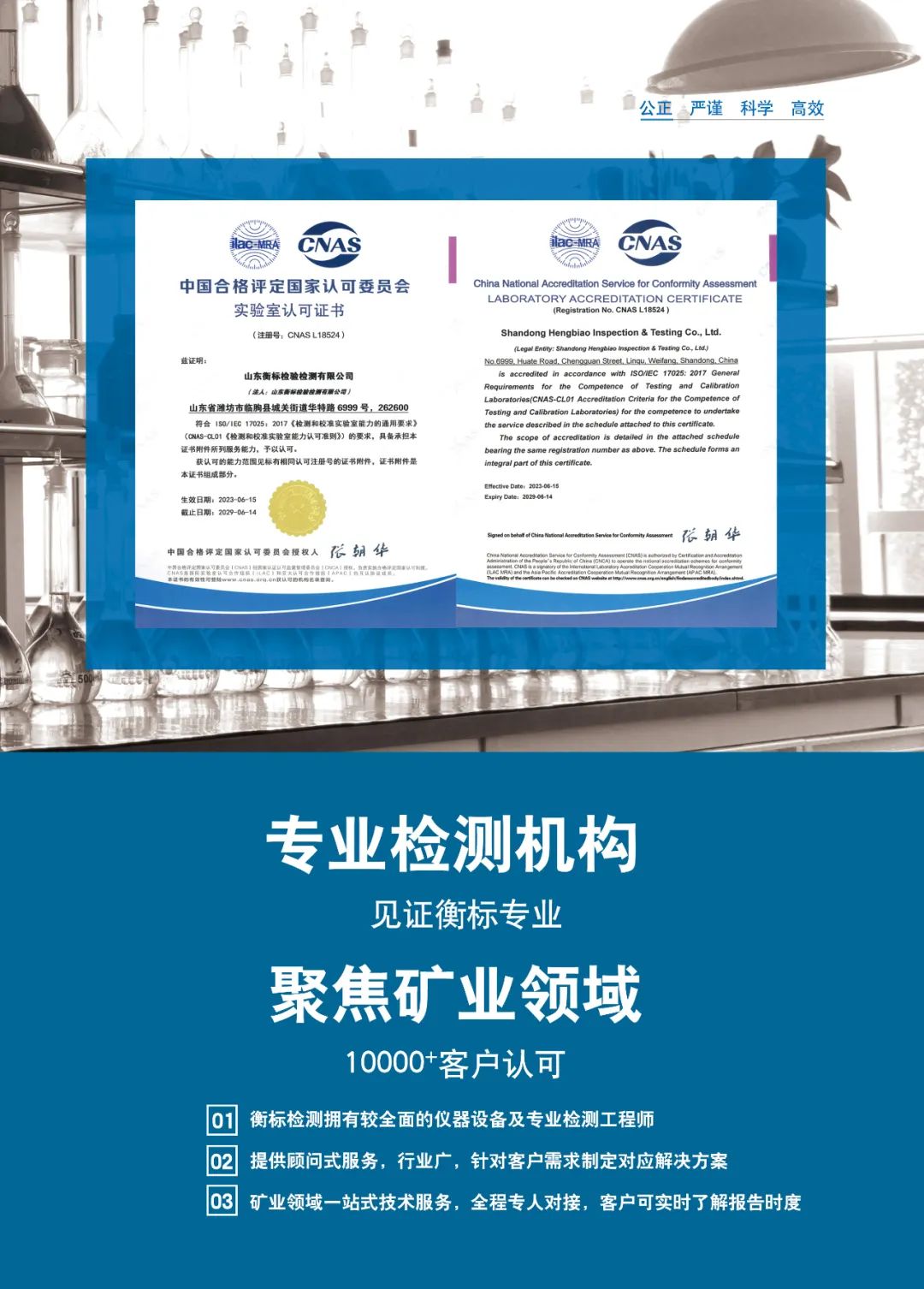

Shandong Hengbiao Inspection and Testing Co., Ltd. is a testing institution with double C qualifications that has passed the qualification accreditation of inspection and testing institutions and the China National Accreditation Service for Conformity Assessment. It has 25 professional inspection and testing personnel, including 10 engineers and laboratory technicians with senior professional titles. A public service platform that provides professional inspection and testing, information technology consulting, education and training and other services for mining and metal materials related industrial chain industries. The institution operates and services in accordance with the (Code for Accreditation of Testing and Calibration Laboratories). The organization consists of chemical analysis room, instrument analysis room, material testing room, physical performance testing room, etc. It has more than 100 major testing instruments and supporting facilities such as X-ray fluorescence spectrometers, atomic absorption spectrometers and ICPs, carbon and sulfur analyzers, spectrophotometers, direct reading spectrometers, impact testing machines, and universal testing machines of the American Thermo Fisher brand.

The detection range includes chemical element analysis of non-metallic minerals (quartz, feldspar, kaolin, mica, fluorite, etc.) and metallic minerals (iron, manganese, chromium, titanium, vanadium, molybdenum, lead, zinc, gold, rare earth, etc.). Composition and physical property testing of stainless steel, carbon steel, copper, aluminum and other metal materials.

The company adheres to the principles of "systematic management, platform-based skills, efficient operation, and professional services", targets the potential needs of customers and society, takes customer satisfaction as its service purpose, and adheres to the philosophy of "fairness, rigor, science, and efficiency". Service policy, committed to providing authoritative and accurate technical services to our customers.

Post time: Apr-23-2024