Shandong Hengbiao Inspection and Testing Co., Ltd. occupies a total area of more than 1,800 square meters, more than 6 million yuan in fixed assets. There are 25 professional inspection and testing personnel, including 10 senior engineers and laboratory technicians. They provide professional inspection and testing, information technology consulting, education and training services for the mining and metal material-related industry chain industries. They are nationally recognized and can independently assume legal responsibilities.Operate and service in accordance with CNAS-CL01:2018 (Criteria for Accreditation of Testing and Calibration Laboratories).There are chemical analysis room, instrument analysis room, material testing room, physical performance testing room and so on.It has more than 200 major instruments and equipment such as Thermo Fisher X-ray fluorescence spectrometer and atomic absorption spectrometer, plasma emission spectrometer, carbon-sulfur analyzer, direct reading spectrometer, impact testing machine, and ** testing machine.

The detection range includes non-metals (quartz, feldspar, kaolin, mica, fluorite, etc.) and metals (iron, manganese, chromium, titanium, vanadium, tungsten, molybdenum, lead, zinc, nickel, gold, silver, rare earth minerals, etc.) Element chemical analysis of minerals, material and physical performance testing of metal materials such as stainless steel, carbon steel, copper, aluminum, etc.

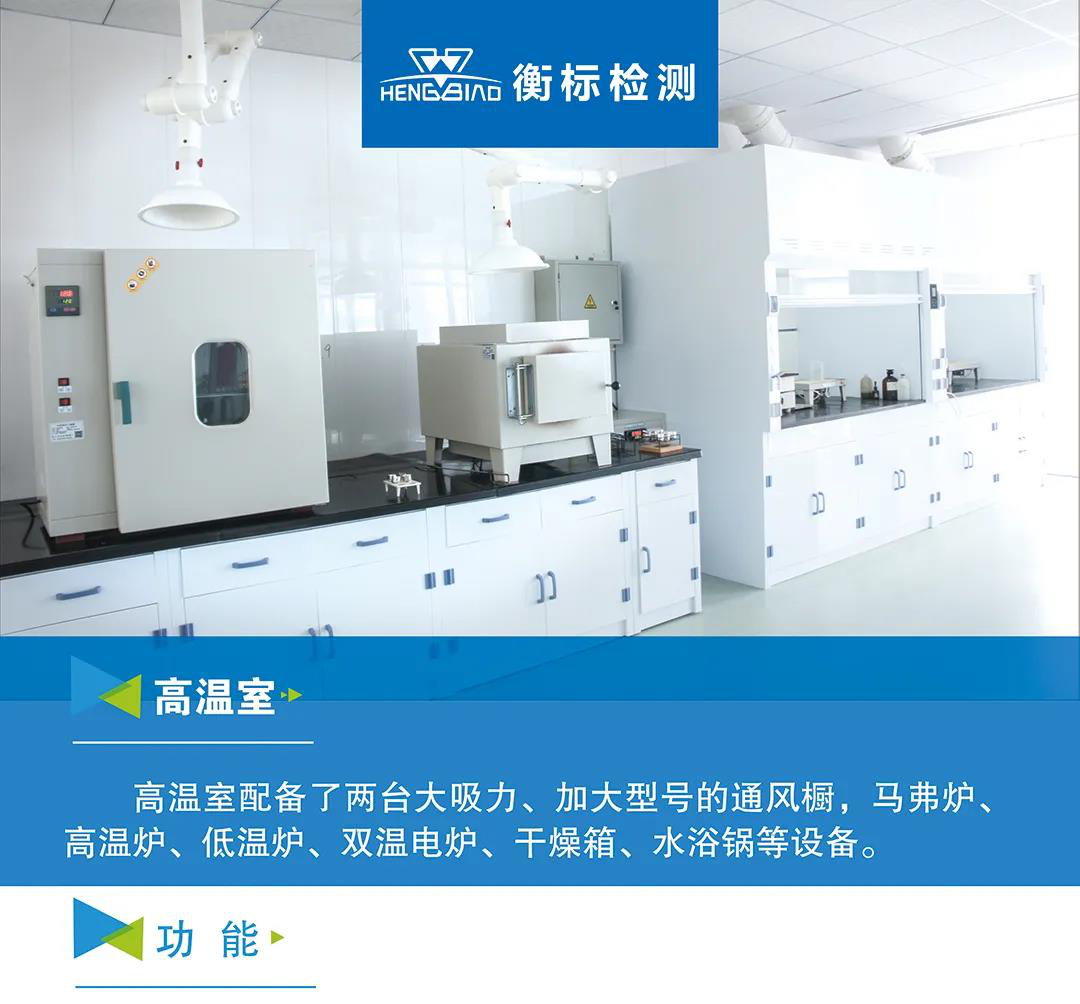

Mainly perform mineral burning, sample drying, heating after sample dissolution, and observation of changes during heating.

Mainly carry out the weighing of mineral sampling and the weighing of medicines.

Mainly perform chemical titration detection of all iron, magnetic iron, titanium, copper, lead, zinc, nickel, chromium, vanadium and other metal elements in iron ore, dissolve various samples, and calibrate solutions.

Atomic absorption spectrometry can generally detect the PPm level (10-6) with a precision of about 1%.The elemental analysis is carried out based on the effect of the atomic vapor in the ground state of the substance on the absorption of characteristic radiation. It can sensitively and reliably determine trace or trace elements.X fluorescence spectroscopy is a fast, non-destructive material measurement method. It can quickly perform qualitative and quantitative analysis of samples.

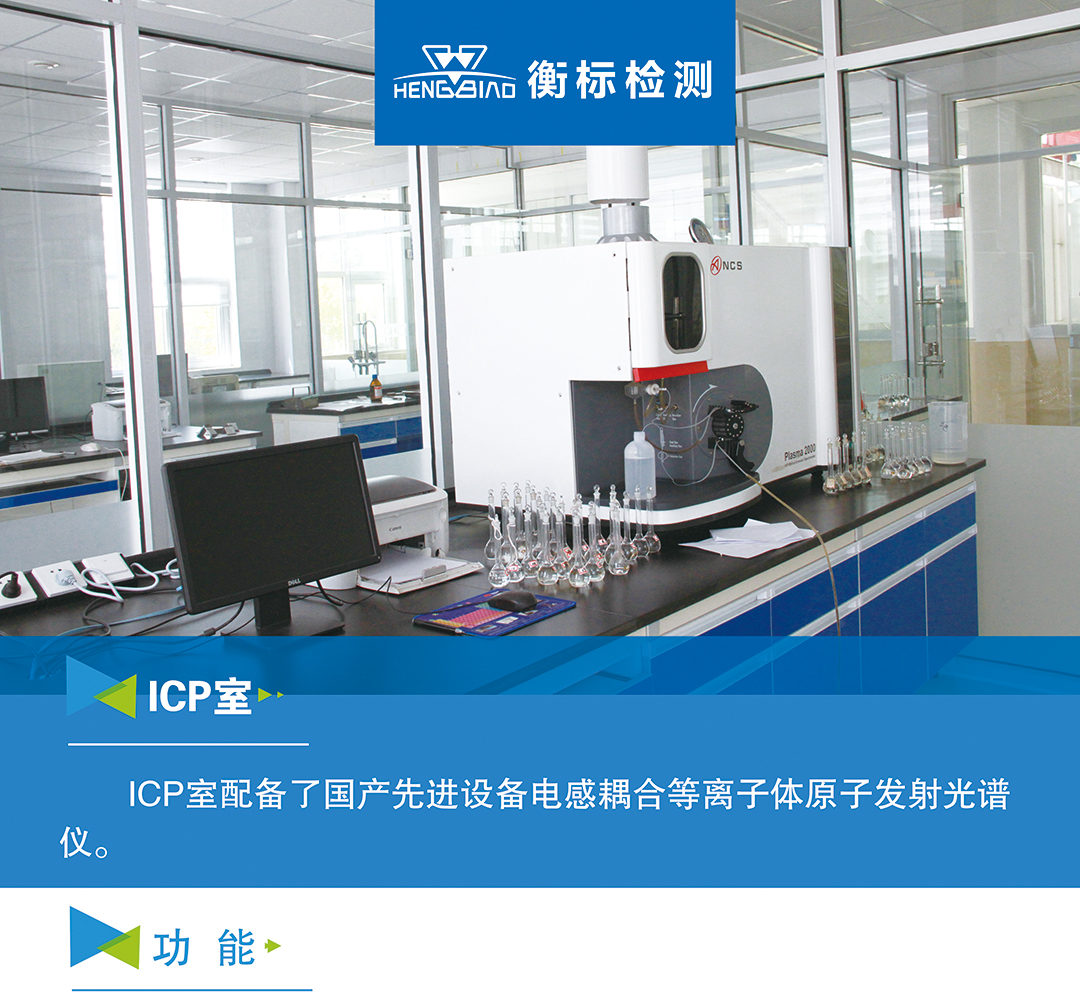

ICP is an atomic emission spectrometry analysis method with plasma as the excitation light source, which can measure multiple elements at the same time.Determine the content of the corresponding element in the sample according to the intensity of the characteristic spectrum. Mainly for the iron content in non-metallic ores, and the full analysis and detection of non-metallic ores.

Spark direct reading spectrometer is mainly used to analyze alloy composition and impurity elements in metal materials.The analytical precision of the instrument is high, and the result is accurate. Mainly used to analyze the content of elements in a variety of matrices such as iron, nickel, copper, aluminum, and titanium.

Mainly for the detection and rapid analysis of element content in non-metallic minerals, rapid detection of sulfur in minerals and particle size analysis of powder minerals, etc., and the detection results are accurate.

Microcomputer screen display hydraulic** testing machine,Mainly used for tensile, compression, bending and shearing mechanical properties of metal materials, from metal material testing to new material testing, the testing machine can meet different requirements of different levels, and serve you with high efficiency and high precision.

The pendulum impact tester is mainly used for impact testing of various metal materials. It adopts semi-automatic control, simple operation and high work efficiency. The remaining energy after the pendulum breaks the sample can be used to automatically raise the pendulum. In the impact test, its superiority can be more reflected.

The company adheres to the principles of “systematic management, platform-based skills, efficient operation, and professional service”, takes the potential needs of customers and society as the goal, takes customer satisfaction as the service tenet, and adheres to the “fair, rigorous, scientific and efficient” principle. Service policy, committed to providing our customers with authoritative and accurate technical services.

Fair, rigorous, scientific and efficient

Shandong Hengbiao Inspection and Testing Co., Ltd.

Looking forward to working with you!

Technical Service Scope of Huate Magnetoelectric Beneficiation Engineering Center

①Analysis of common elements and detection of metal materials.

② Impurity removal and purification of non-metallic minerals such as quartz, feldspar, kaolin, bauxite, talc, pyrophyllite, etc.

③The beneficiation of ferrous metal ore such as iron, titanium, manganese, chromium, vanadium, etc.

④The beneficiation of weak magnetic minerals such as wolframite, tantalum-niobium, garnet, tourmaline, rare earth, etc.

⑤ Comprehensive utilization of secondary resources such as various tailings and smelting slag.

⑥ Non-ferrous metal ore needs to be combined with magnetic separation + gravity separation or flotation.

⑦Mineral intelligent sensor sorting

⑧ Material crushing, ball milling, grading and other powder ultra-fine processing

⑨ EPC turnkey projects such as crushing, ore grinding, magnetic (heavy, flotation) separation, dry discharge, etc. in the mine dressing plant.

Post time: Feb-26-2021