Shandong Huate Magnet Technology co.,LTD was founded in 1993, the company strictly in accordance with the REQUIREMENTS of ISO9001 quality management system, set up a perfect product quality management and control system, formulate and implement unified quality inspection standards, technical standards and testing means, to ensure the stability and improvement of product quality.The company introduces the international advanced lean management mode, implements 6S management method, from the processing and production to the final assembly of finished products, through strict control of product quality, to provide users with first-class products and quality services.

The company has a reasonable and effective quality management model, always adhere to the quality management concept of “quality is the life of the enterprise”, constantly carry out market research, committed to the manufacture of modern mining operation requirements of high-end, intelligent, green, environmental protection of high-tech mineral processing equipment.

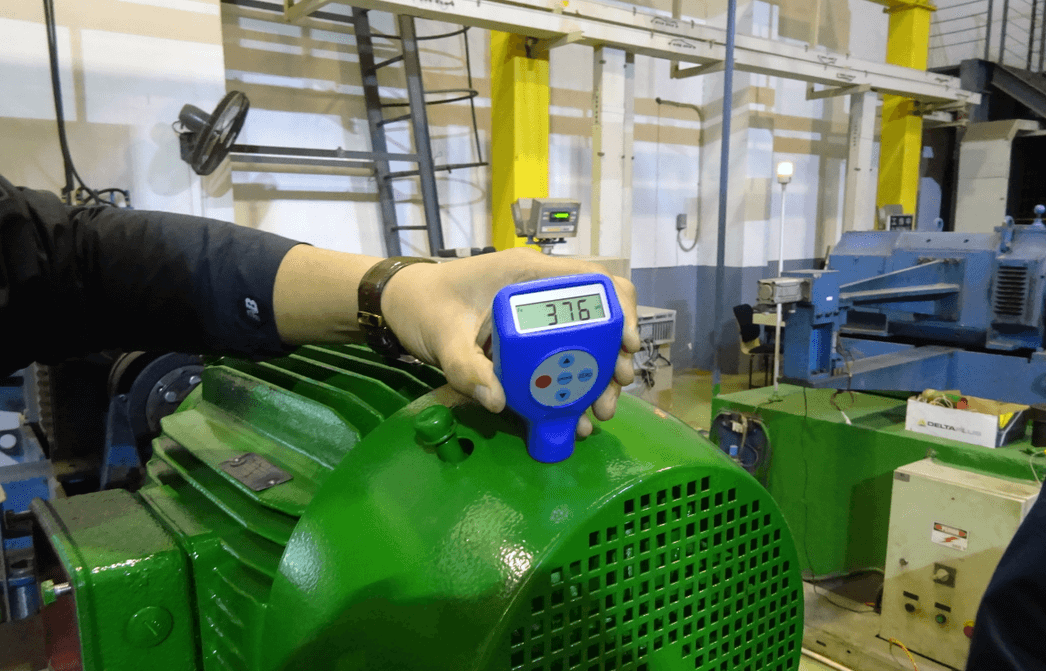

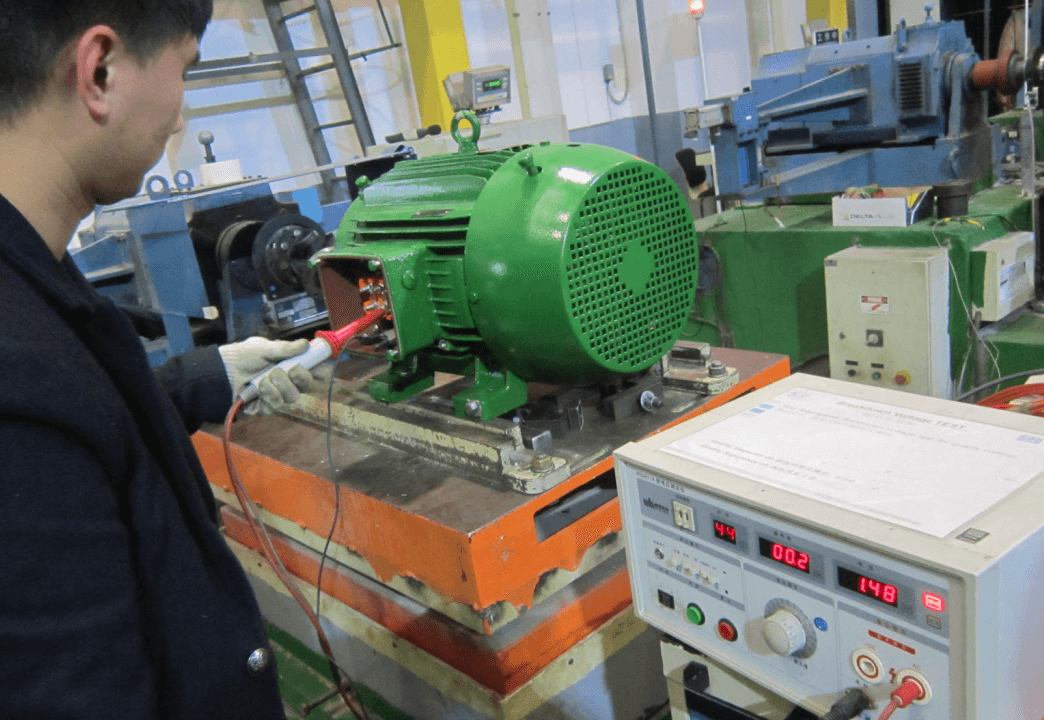

Since 2016, the company has intensified its quality control efforts and successively purchased: British Easyhigh E125-2 shot blasting surface sample, F108-2D hydraulic adhesion tester;

South Korea MP – A2L handheld magnetic powder flaw detector, the American G116C – type 1 paint dry wet thermometer, FLUKE1508 digital insulation resistance tester, XXQ2005 portable X-ray flaw detection, ultrasonic flaw detector, the HS – 600 type DLQ – III current detector (large current protection characteristic test bed) and other advanced testing instruments and equipment, from raw materials into the factory to strict inspection, according to the requirements of the quality management system, focus on product machining, welding, assembly production process quality control, stability and improve the quality of products of the company.

In 2013, it passed the sampling test of “RCDC-10 oil-cooled electromagnetic iron eliminator and RCDFJ-14T3 oil-cooled electromagnetic iron eliminator” by Shandong Bureau of Quality Supervision.

In 2014, it passed the sampling test of “LHGC2.0BZT Strong oil cooling vertical ring high gradient magnetic separator” by Shandong Quality Supervision Bureau.

In 2015, it passed the sampling test of “RCDEJ-1471 oil-cooled electromagnetic iron eliminator and CTB (N, S) -1545 permanent magnet drum-type magnetic separator” issued by Shandong Bureau of Quality Supervision.

The improvement of quality is inseparable with the development and expansion of the company. With the continuous development and expansion of the company, the quality of the company’s products has really made a qualitative leap, from a small workshop enterprise unknown to one of the few mineral processing equipment manufacturing enterprises in China.

From permanent magnet iron remover and magnetic separator to vertical high-gradient magnetic separator and slurry magnetic separator with multiple patents;From manual welding seam not straight and not even to robot automatic welding, to welding parts ultrasonic, radiographic inspection pass the standard once, condensation of The precipitation and pursuit of product quality.

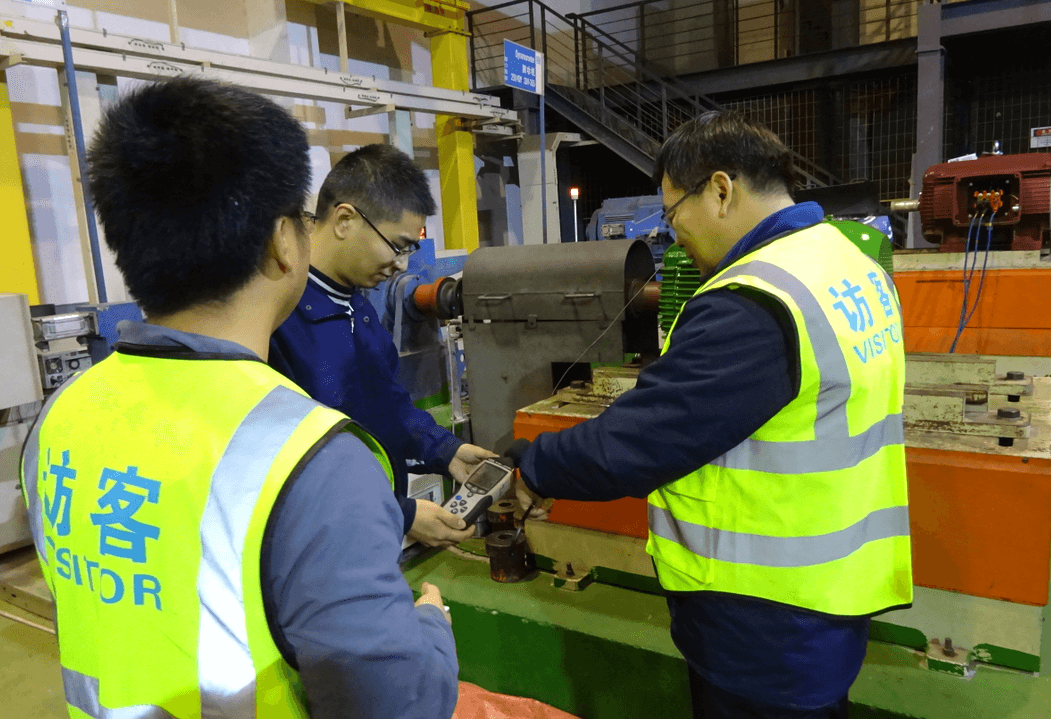

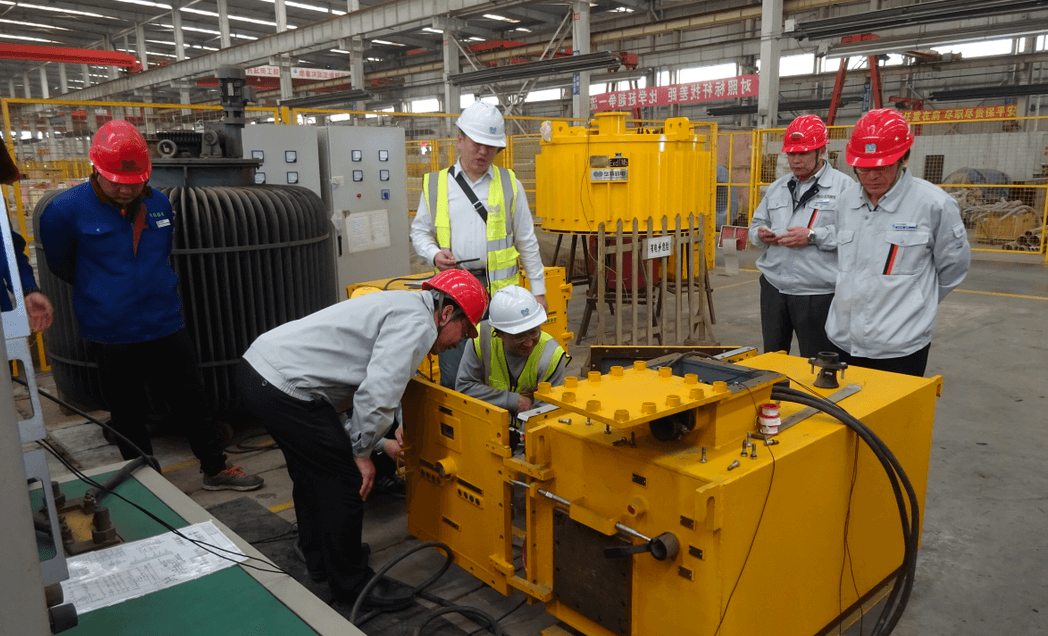

The product quality of mineral processing equipment has been recognized by customers from Germany, Czech, Iran, Philippines, South Africa and other countries, as well as SGS, BV, TUV and other international well-known supervision companies, which has laid a solid foundation for expanding the export of our products.

Post time: Nov-04-2020