【Huate Mineral Processing Encyclopedia】Purple upstart! Huate Magneto Power Boosts High-Quality Development of Fluorite Sorting Industrialized Production Line

Fluorite, also known as fluorite, is rich in yttrium called yttrium fluorite. The crystals are often cubic, octahedron, and less rhombic dodecahedron. A common mineral in nature, some samples can emit light when subjected to friction, heating, ultraviolet radiation, etc. It is not often used as a gem due to its brittleness and softness. In industry, fluorite is the main source for the extraction and preparation of various compounds such as fluorine and hydrofluoric acid, and fluorite specimens with bright colors and beautiful crystal forms can be used for collection, decoration and carving art.

Ore Properties and Mineral Structure

Fluorite is composed of CaF2, which contains 48.67% fluorine, 51.33% calcium, and sometimes rare elements. It is often symbiotic with quartz, calcite, barite and metal sulfide, in granular or massive aggregates, often yellow and green. , blue, purple, etc., less colorless, vitreous luster, hardness 4, density 3.18g/cm3, heated or fluorescent under ultraviolet light. Fluorite is insoluble in water, soluble in sulfuric acid, phosphoric acid and hot hydrochloric acid, boric acid, hypochlorous acid, and can react slightly with strong bases such as potassium hydroxide and sodium hydroxide, with a melting point of 1360 °C.

Application areas and technical indicators

Fluorite contains the halogen element fluorine, which is the main raw material for the preparation of fluorine compounds, and is widely used in steelmaking, non-ferrous metal smelting, cement, glass, ceramics, etc. due to its low melting point. Available as optical fluorite and craft fluorite.

Table 1 Main uses of fluorite

|

Application field |

The main purpose |

|

Metallurgical Industry |

Steelmaking flux, slag removal agent, enamel brightener, glass opacifier |

|

Chemical industry |

Raw materials for the production of hydrofluoric acid, basic raw materials such as Freon |

|

Cement industry |

Mineralizer for the production of cement clinker, which can reduce the sintering temperature and save energy |

|

Glass industry |

Raw materials for the production of emulsified glass, opaque glass and tinted glass, lenses |

|

Ceramic industry |

Solvents and opacifiers for the manufacture of ceramics, enamel processes |

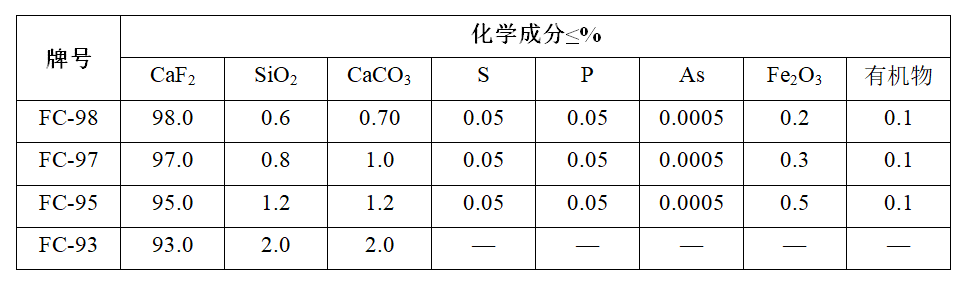

Technical index requirements

Metallurgical industry standards divide fluorite products into three types: fluorite concentrate (FC), fluorite lump (FL) and fluorite fines (FF).

Table 2 Chemical composition of fluorite concentrate

Processing Technology

Beneficiation and Purification

Minerals symbiotic with fluorite are: quartz, calcite, scheelite, apatite, cassiterite, wolframite, pyrite, sphalerite, lapis lazuli, muscovite, galena, chalcopyrite, rhodochrosite Manganese ore, dolomite, potassium feldspar, spinel, barite, etc. According to the difference in the properties of the associated minerals in fluorite, separation and purification are carried out by flotation, magnetic separation, gravity separation and other beneficiation methods.

①Flotation

Flotation is the most important way of fluorite beneficiation. The general process is to collect fatty acids after grinding, and select qualified fluorite concentrate products through multiple selection processes; for the associated sulfide minerals, yellow Drugs are selected, and the associated barite, calcite, muscovite, etc. are separated by inhibitors.

②Reelection – flotation

When the ore grade is low or contains a lot of coarse conjoined bodies, the combined process of gravity separation and flotation is generally used.

③ Magnetic separation – flotation

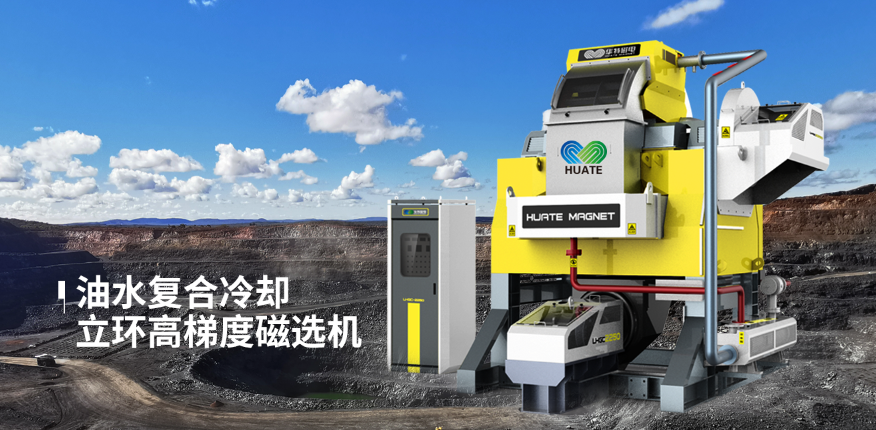

When there are many magnetic iron or iron oxides in the ore, the drum magnetic separator can be used to separate the strong magnetic iron or the vertical ring magnetic separator to remove the weak magnetic iron oxide and then go through the flotation process; if there are few iron minerals in the original ore, However, when the iron content of flotation fluorite concentrate exceeds the standard, vertical ring or electromagnetic slurry high gradient magnetic separator can be used to remove iron oxide minerals in fluorite concentrate by strong magnetic separation, so as to improve the quality of concentrate.

Oil-water composite cooling vertical ring high gradient magnetic separator

Low temperature superconducting magnetic separator

Drum Magnetic Separator

Preparation of hydrofluoric acid

Hydrofluoric acid is a main chemical product. Hydrofluoric acid is obtained by decomposing fluorite with sulfuric acid, the so-called sulfuric acid method. It is extremely corrosive and has a wide range of uses. It is often used for sand removal in metal castings, graphite ash removal, Metal cleaning, semiconductor manufacturing, ceramic processing, etching glass, petroleum catalysts, etc.

Fluorite ore removal test

The CaF2 content of the fluorite rough concentrate obtained by flotation of a rare earth tailing in Bayan Obo is only 86.17%, which is quite different from the requirements for qualified concentrate products. In addition to fluorite, the rough concentrate also contains rare earth and hematite. , limonite, calcite, apatite, sodium pyroxene, amphibole, biotite and other minerals. The fatty acid soap collectors used in fluorite flotation have a certain collection effect on iron-bearing minerals. Among these impurity minerals, hematite, limonite, sodium pyroxene, amphibole, and biotite are all weakly magnetic, and can be removed by strong magnetic separation to improve the quality of fluorite concentrate.

-200 mesh fluorite coarse concentrate with a fineness of 93.50% was subjected to a comparative test of impurity removal and purification by two high-strength magnetic separation processes, such as vertical ring + electromagnetic slurry high gradient magnetic separator and vertical ring + superconducting magnetic separator.

In the comparison test of strong magnetic impurity removal, it was found that some minerals such as hematite, limonite and biotite with relatively high specific magnetic susceptibility can be effectively removed by a strong magnetic separation of the vertical ring, and the CaF2 grade of the fluorite concentrate was increased from 86.17%. Then the iron-bearing minerals with weak magnetic properties are removed by electromagnetic slurry and superconducting magnetic separator, and the CaF2 grade of fluorite concentrate is increased to 93.84% and 95.63% respectively, both reaching FC-93 and FC-95. quality standard. The beneficiation effect of vertical ring and electromagnetic slurry high gradient magnetic separator and low temperature superconducting magnetic separator is more obvious, which can provide a reliable technical basis for the strong magnetic impurity removal and purification of such minerals.

Applications

Vertical ring high gradient magnetic separator is used in a rare earth magnetic separation project in Inner Mongolia

The project adopts two 1.7T vertical ring high gradient magnetic separators and one 5.0T low temperature superconducting magnetic separator, which can effectively improve the grade of fluorite concentrate, achieve good recovery of rare earth, and increase production and efficiency.

A rare earth beneficiation strong magnetic separation project in Sichuan, the project uses 8 sets of 1.4T vertical ring high gradient magnetic separators for separation and recovery of rare earths, and the effect is good。

Post time: May-06-2022