For 28 years, Huate Magnet has been driven by scientific and technological innovation, focusing on the research and development and production of high-end mineral processing equipment, superconducting magnet technology and energy-saving and environmentally-friendly high-tech magnetoelectric products. The service scope covers mining, coal, electric power, metallurgy, non-ferrous metals, More than 10 fields such as environmental protection and medical care have provided optimized solutions for more than 20,000 customers worldwide.Adhering to the service concept of “Customers are always the first”, the company continues to promote the reform of the service system, strives to create more convenient, personalized and customized services for customers, and leads and promotes the transformation and upgrading of industry services to become globally competitive. Of magnetic application system service providers keep moving forward!

Huate Magneto-electric boutique project case show

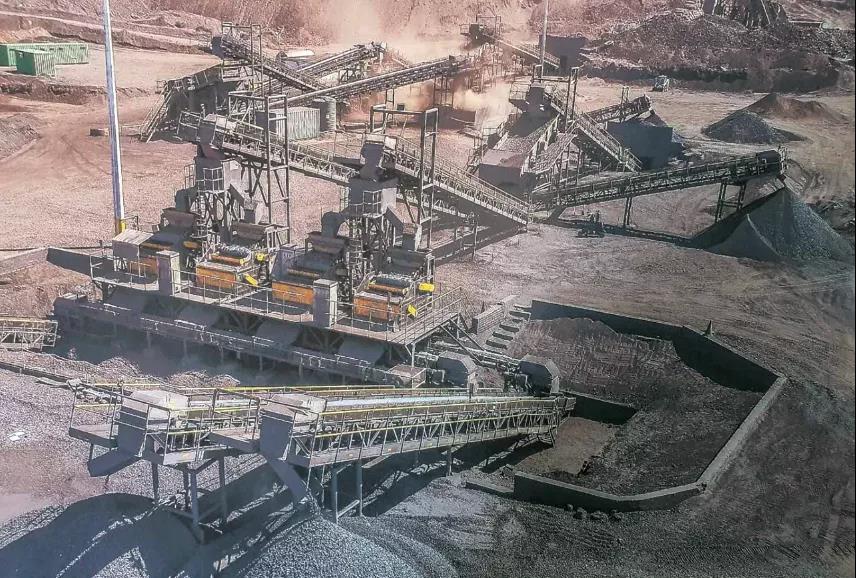

Australia iron tailings project

The project has a designed annual production capacity of 55 million tons. Our company supplies a complete set of magnetic separation equipment, including 14 LHGC-3000 vertical ring high gradient magnetic separators and 14 CTB-1540 drum magnetic separators. Recovery of hematite.

South Africa Manganese Iron Ore Project

This project is a manganese ore dressing plant project constructed by our company in the first phase of the general contract in South Africa, with an annual output of more than 800,000 concentrates.

Austrian Quartz Sand Project

The quartz sand concentrator customized the Huate LHGC2500 vertical ring magnetic separator to completely replace the flotation purification process in the original process.

India Iron Ore Project

This project is a hematite concentrator constructed by our company as a general contract in India, and the production scale can reach 700,000 tons per year.

Lianyungang Iron Mine Project

The project is a large-scale concentrator for imported ore processing. According to the imported ore, it can process magnetite and hematite. It is also a short-process and large-scale modern concentrator. Our company’s refined slag reduction magnetic separator, LHGC3500 large-scale vertical concentrator The ring high gradient magnetic separator and other products are all applied in batches in this concentrator, and the effect is good.

Benxi Iron Mine Project

The project processes 13 million tons of iron ore annually. The mine belongs to ultra-fine low-grade magnetite. It adopts a new type of magnetic separator for refinement and slag reduction to realize a modern large-scale mine with short process, large-scale and low-cost.

Anhui Quartz Sand Project

The project has an annual output of 500,000 tons of quartz sand. The 2745 ball mill production line (CTN1230 permanent magnet drum➕LHGC2500 vertical ring) is used to remove mineral impurities in the quartz sand and obtain high-purity quartz sand with particle size and impurity content that meet the requirements.

Anhui Quartz Sand Project

The project has an annual output of 1 million tons of quartz sand. It uses 4 sets of LHGC2500 oil-water composite cooling vertical ring high gradient magnetic separator + 4 sets of SGB strong magnetic plate magnetic separator. The purification effect is good, and the quality index of the refined sand obtained is excellent.

Malay West Lai Iron Ore Project

This plant is a magnetite beneficiation project constructed by our company as a general contractor, with a production scale of 4 million tons of raw ore processing capacity per year.

Anhui Quartz Sand Project

The project has an annual output of 500,000 tons of quartz sand, which is the second 2745 ball mill production line of the project to support two LHGC2500 vertical ring high gradient magnetic separator production lines.

The project has an annual output of 500,000 tons of quartz sand. The first-phase stone-milled quartz sand production line uses LHGC2000+LHGC2500 vertical ring high-gradient magnetic separators in series, which has a good separation effect.

Nantong Sea Sand Project

The project is a sea sand dressing plant, with an annual processing capacity of 600,000 tons of sea sand. Using LHGC2500 vertical ring high gradient magnetic separator + 2 HTDZ1500 electromagnetic slurry high gradient magnetic separator, the separation effect is good.

Company Profile

Shandong Huate Magnetoelectric Technology Co., Ltd. (stock code: 831387), with a total area of 270,000 square meters, a registered capital of 64.75 million yuan, total assets of 520 million yuan, and more than 800 employees, specializes in the production of cryogenic superconducting magnetic application equipment, Magnetic separators, magnetic separators, magnetic stirrers, ultra-fine crushing and grading equipment, complete sets of mining equipment, complete sets of non-ferrous metal separation equipment, electromagnetic fluid seawater floating oil separation and recovery equipment and other products are exported to the United States, Germany, Brazil, In India and other countries, there are more than 20,000 customers.

The company has a national key mineral processing laboratory covering an area of 6000 square meters, 120 full-time or part-time experimental researchers, complete laboratory processing equipment, complete testing and analysis instruments, good product experimental conditions, and various experiments There are more than 200 sets of equipment and instruments, 60% of which have reached the domestic leading level and 20% of them have reached the international advanced level. With the development of magnetic separation equipment manufacturing as the starting point, the focus is on the development of superconducting magnets and superconducting magnetic separation in the field of magnetic equipment technology. Research on large-scale magnetic application technology equipment such as machine, high-gradient magnetic separator, stirrer, etc.

Our company can provide customers and scientific research institutes with complete beneficiation process solutions and beneficiation experimental equipment from crushing, screening, dry separation, grinding, wet weak magnetic separation, wet strong magnetic separation, etc., to provide the feasibility of the construction of the beneficiation plant Guiding advice.

Post time: Mar-24-2021