Powder material purification tool! An article to understand the advanced control system of Huate HCT dry powder electromagnetic separator control system

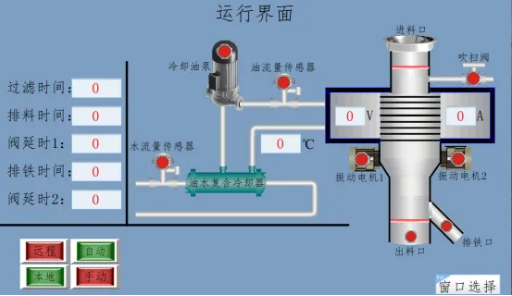

HCT series dry powder electromagnetic iron remover is suitable for Graphite, Lithium Carbonate, Lithium Hydroxide, Lithium Iron Phosphate, Quartz, Cobalt Oxide and other fine micropowder industry demagnetization requirements, the level of iron removal accuracy up to PPM level and PPB level. Equipment working principle: the excitation coil is energized, in the center of the coil can produce a high intensity magnetic field, the media induction produces a high gradient magnetic field, when the powder through the magnetized media, in which the magnetic material is captured, non-magnetic material through the vibration outflow, so as to obtain high purity products; when the magnetic media adsorption capacity reaches saturation, the lower end of the distribution valve to the magnetic material discharge port, the electromagnetic coil cut off the power so that the media demagnetization, and the vibration motor increases the amplitude. At the same time, the vibration motor increases the amplitude, and the magnetic material is discharged from the discharge port after detaching from the medium.

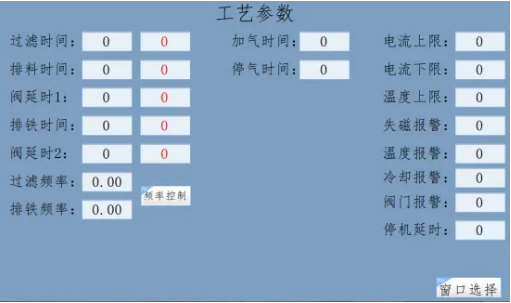

HCT series dry powder electromagnetic separator control system has on-site manual, on-site automatic and remote automatic three modes of operation, through the control cabinet switch for operation mode conversion. On-site manual mode manual control of equipment for the implementation of components for the installation and commissioning, troubleshooting; on-site automatic mode, through the touch screen "process parameters" interface to set the operating parameters, since the control of the automatic cycle of the equipment; remote automatic mode, through the touch screen "process parameters" interface or remote communication set parameters, remote start and stop, control equipment; remote automatic mode, through the touch screen "process parameters In remote automatic mode, through the touch screen "process parameters" interface or remote communication set parameters, remote start-stop, control equipment one key start-stop.

Control system performance characteristics

◆ Taking programmable controller as the core and built-in fault identification program, it collects equipment operation data in real time, monitors the operation status and controls the actuator to complete the action; it operates according to the process flow in full-automatic cycle, with one-key switch on/off and a high degree of automation.

◆ Flexible control is realized through the human-machine interface, and users can conveniently adjust the process running parameters of the equipment according to their needs; at the same time, the alarm information can be actively pushed to assist the field personnel in troubleshooting the equipment.

◆ The excitation power rectifier adopts advanced adaptive PID algorithm, closed-loop constant current operation, avoiding the influence of magnet heating on the magnetic field; at the same time, it has the characteristics of short magnetizing time and quick demagnetizing time, which can further improve the working efficiency of the equipment.

◆The control system can be integrated with Profinet, Profibus-DP, Modbus and other industrial protocols, and the port can be connected with DCS, SCADA, MES and other software, which is convenient for the construction of "digital factory".

◆ Through the touch screen [manual interface], it can realize the debugging and overhauling of the equipment.

◆ Setting and modifying the parameters of automatic control through [Process Parameter] interface.

◆ View the running status of the equipment through [Running Interface] interface.

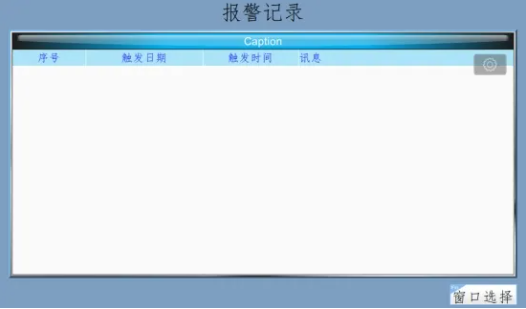

◆ Through [Alarm Record] interface, view the history alarm record of the equipment.

Applications

Post time: May-16-2024