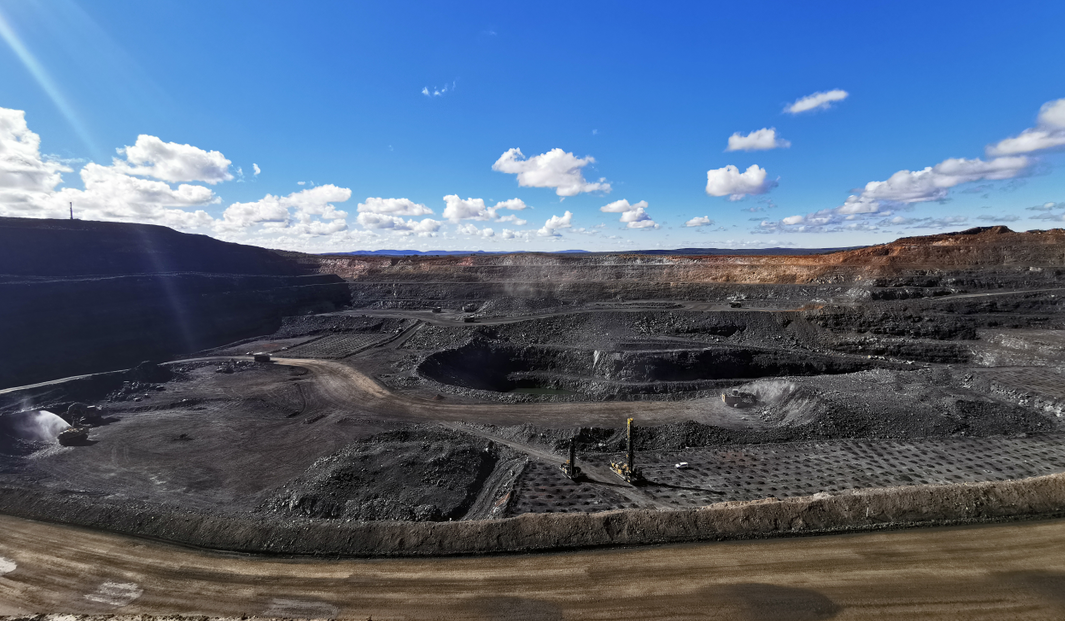

Due to the large-scale mining of ferrous metal mineral resources in my country, its limited resources are becoming increasingly scarce. Therefore, the requirements for mineral processing equipment are getting higher and higher, especially the comprehensive utilization of tailings is directly related to the persistence of my country’s resources. The question is how to implement the policies of energy conservation, consumption reduction, and emission reduction proposed by the state, maintain the long-term utilization of resources, and maximize the value of resources has become an important issue facing the mining industry.

At present, the tailing recovery airport used in the magnetic separation of ferrous metal ore tailings in my country is about 1600Gs, and it is difficult to recover the weakly magnetic minerals in the tailings. For this reason, there is an urgent need to develop a beneficiation equipment with high field strength and capable of reducing the iron content of tailings to maximize the current utilization of mineral resources in my country.

Shandong Huate Magnetoelectric Technology Co., Ltd. has been committed to the research of magnetite magnetic separation tailings recovery equipment since 2005. At present, a large number of ferrites are produced as magnetic tailings recovery machines, and three series have been formed. Products with multiple specifications have become the main equipment for tailings recovery. In order to further increase the iron recovery rate of the tailings recovery equipment, after thorough investigation, demonstration and analysis tests, the use of neodymium iron boron magnetic materials and the method of unloading in the non-magnetic zone has further improved the iron recovery rate, and the unloading is easy, which can meet the requirements of use.

Structure and working principle of mid-field strength semi-magnetic self-unloading tailings recovery machine

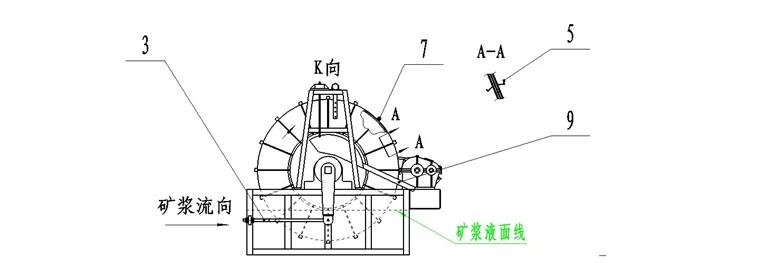

The mid-field strong semi-magnetic dump tailing recovery machine uses neodymium iron boron as the magnetic material. The separation space has a medium magnetic zone and a weak magnetic zone. The magnetic poles alternately form a semi-circular ring magnetic system. A rotatable casing is provided outside the magnetic system. , The magnetic system is fixed, a part of the shell is immersed in the pulp, and the magnetic particles in the pulp are continuously absorbed by the method of continuous rotation. The magnetic particles continue to tumble along with the rotation of the casing, so that the non-magnetic materials in the magnetic materials are continuously washed out. The upper right part of the semi-annular magnetic system has no magnetic field. When the magnetic materials enter the non-magnetic area, under the action of the washing water and the gravity of the material, Unload the material into the concentrate tank.

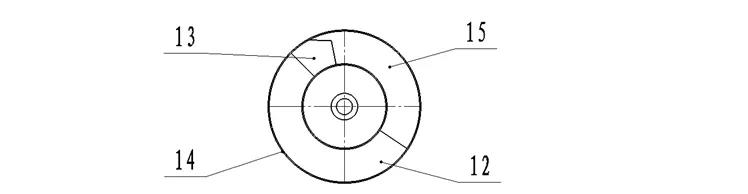

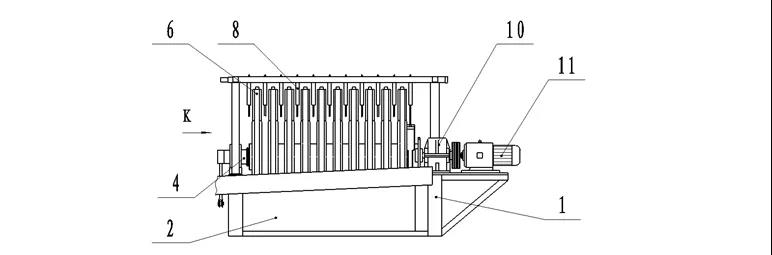

The mid-field strength semi-magnetic self-unloading tailings recovery machine is a disc-type combined structure, and the number of magnetic discs can be determined according to the requirements of the processing capacity. Its structure is shown in Figure 1, 2, and 3. 1- frame; 2- slurry tank; 3- disk adjustment mechanism; 4- central shaft; 5- deflector; 6-collecting tray; 7- agitating block; 8- flushing pipe; 9- holding chute; 10 -Reducer; 11-motor; 12-strong magnetic area; 13-weak magnetic area; 14-fixed disk; 15-non-magnetic area.

The frame is made of welded steel and is mainly used to support the central shaft, install the transmission system and install the slurry tank.

The magnetic disc is a semi-magnetic structure, and a closed collecting disc is installed outside, a magnetic conductive plate is sandwiched between the double-layer magnetic steel, and the lower part of the collecting disc is immersed in the slurry tank 2.

The magnetic disc is provided with a middle magnetic field, a weak magnetic field and a non-magnetic area, and it is fixed on the central axis.

The two ends of the collecting pan are provided with a plurality of guide plates distributed in a ray shape, and a plurality of evenly distributed stirring blocks are provided on the outer periphery.

At present, some concentrators in my country use medium-field-strength disk tailings recovery machines, but due to the poor desliming effect, the magnetic material will suck back when the magnetic material enters the non-magnetic area from the medium magnetic field, and the disk and scraper wear quickly. , Subject to certain restrictions in use.

In view of the above situation, our company adopts a mid-field-strength semi-annular disk with a fully-sealed neodymium-iron-boron structure to be fixed on the central axis, and the central axis is fixed without rotation. Rotatable collecting pan, the lower part of the collecting pan is immersed in the slurry flow trough to absorb magnetic materials. A motor and a reducer are used to drive the collecting tray to rotate, and the adsorbed magnetic material passes through the middle magnetic field and weak magnetic field, and then discharges after reaching the non-magnetic field, which solves the above problems.

A material chute is arranged between each collecting pan, and the magnetic material on the collecting pan is washed down and flows out along the material chute.

The transmission system is composed of a frequency conversion motor, a reducer, a coupling, a transmission sleeve, etc. The above-mentioned parts are installed on the central shaft and the frame to realize the continuous rotation of the collecting tray.

The control cabinet is equipped with inverters, control switches and other components to control the rotation speed of the magnetic disc at any time.

The permanent magnet in the magnetic area is composed of a single piece or multiple pieces in the thickness direction, and a fixed disc web is sandwiched in the middle. The magnetic zone adopts multiple sets of magnetic pole pairs with opposite polarities to be arranged alternately. During the continuous rotation of the collecting pan, the magnetic materials are constantly tumbling in the collecting pan and in the water to wash and desludge, so that the recovered magnetic materials are combined with ordinary tailings. Compared with the recycling machine, the purity is higher and the recycling effect is better.

A weak magnetic zone is set between the magnetic field and the non-magnetic zone in the disk. When the magnetic material enters the non-magnetic zone, due to the weak magnetic field transition zone and the absorption area of the weak magnetic field gradually decreases, the back migration phenomenon of the magnetic material is greatly reduced. The inclined baffle on the material tray also prevents the back movement of magnetic materials and the leakage of materials, and can make the magnetic materials gradually move down. Due to the action of gravity and washing water, rapid unloading is realized.

The collecting tray is a hollow and fully sealed structure, and the surface for adsorbing magnetic materials is composed of non-magnetic materials. On the collecting tray, the guide plate has ribs on the outside, which is inclined at a certain angle with the end surface of the collecting tray. The main purpose is to prevent magnetism. Back movement of materials and leakage of materials. In order to reduce the deposit of ore slurry, a plurality of stirring blocks for stirring the ore slurry are arranged around the collecting pan, and at the same time, the abrasion of the collecting plate due to the deposit of the ore slurry is also reduced.

Industrial production application

Analysis of the recovery effect of the midfield strength semi-magnetic self-unloading tailings recovery machine

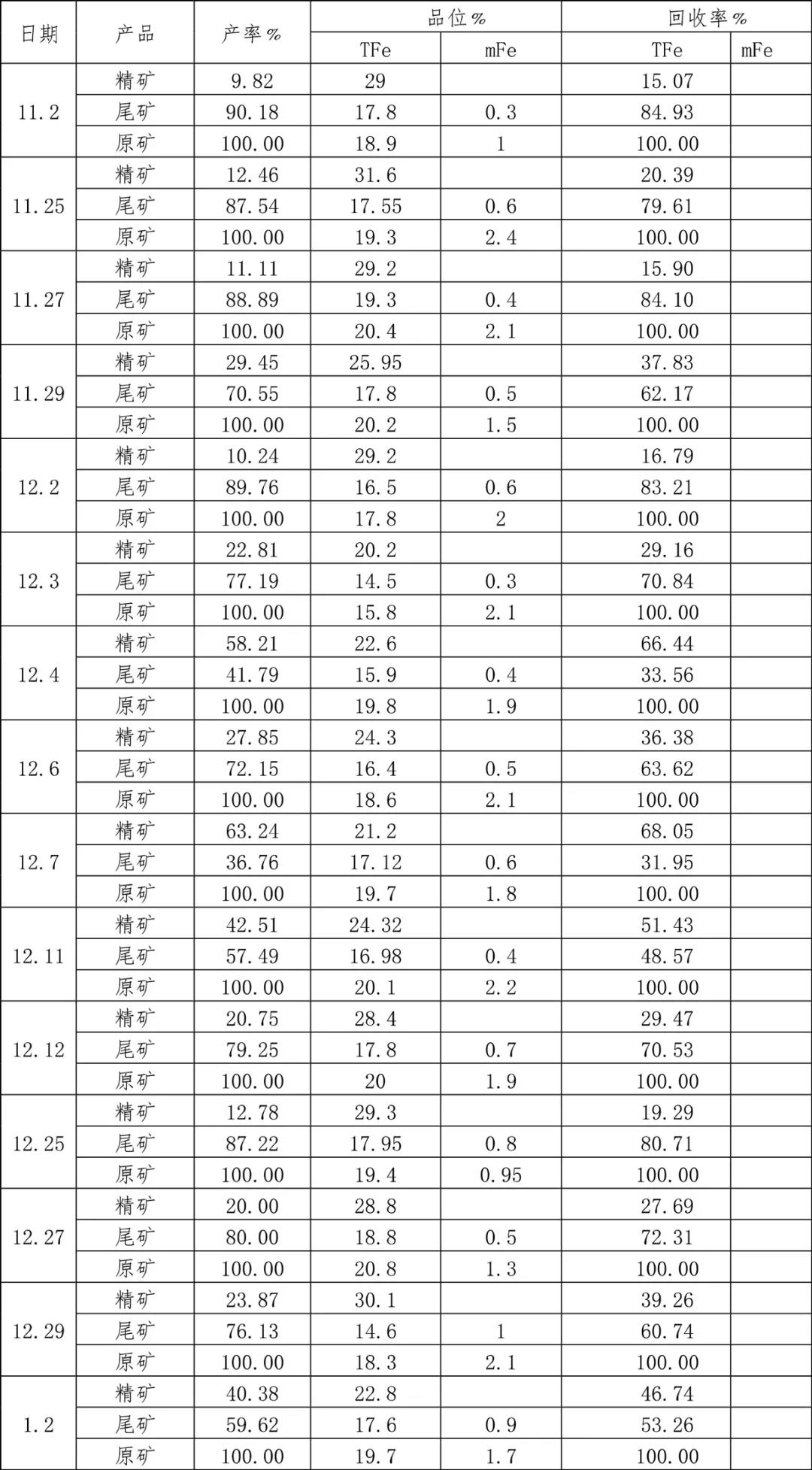

A medium-field strength semi-magnetic self-unloading tailings recovery machine with a model of YCBW-15-8 put into use by a mining company is installed behind the tailings recovery machine composed of ferrite in the magnetic system. After more than half a year of operation, The equipment is operating normally and the recovery effect is good. After many sampling tests, the results are satisfactory. The results of multiple sampling tests are as follows:

Through the above data analysis:

The recovery effect of this equipment: the grade of tailings is reduced by 2.16% after sorting, the grade of magnetic iron is reduced by 1.27% after sorting, and the average grade of middle ore is 26.53%. The recovery effect is obvious.

Market prospects and economic benefits

At present, there are many magnetic separation enterprises in China, and only a few of them use ferrite tailings recovery machines, but do not use mid-field strength semi-magnetic self-unloading tailings recovery machines. Therefore, the market prospect is broad. If 20% of the magnetic The processing plant invests in this equipment, calculated based on 300 units per year and model YCBW-15-8. Each unit can recover 7t/h of dry ore per hour, 168t/h of dry ore per day, and 330 days of work per year, total recovery 55.44 million tons, and a total of 16.632 million tons were recycled by 300 units. The economic benefits are considerable, and the use of this equipment can reduce the waste of a large amount of mineral resources for the country every year.

At present, the grade of tailings of ferrous metal ore in my country is generally high after sorting, causing a lot of waste of resources. Mineral resources are the basis for human survival and development. More than 95% of energy and 80% of industrial raw materials in my country are derived from mining. With the rapid development of my country’s economy, the demand for mineral resources continues to increase. On the one hand, my country’s mineral resources are facing severe pressure from increasing scarcity. High-grade, easy-to-sort mineral resources are declining, and low-grade, difficult-to-sort mineral resources are increasingly being valued. The development and research of tailings recovery machines above 300mT has a positive effect on reducing national resource waste and increasing the utilization rate of mineral resources. From the perspective of development and application effects, it has effectively improved the recovery rate of magnetic ore. It meets the design requirements and is a product worthy of promotion and application.

Post time: May-12-2021