At present, with the development of global industrial production, the scale of utilization of various mineral resources continues to expand, whether it is metallic or non-metallic ore, the consumption is increasing sharply. As a result, the clustering, large-scale, and intelligent development of sorting equipment has become a new goal of the mining industry. In addition, the distribution of global mineral resources is very uneven. Most mineral resource reserves are concentrated in a few countries. For example, the combined iron ore reserves of Australia, Brazil, and Russia account for 54% of the global iron ore reserves; copper in Chile, Australia, and Peru The sum of mineral reserves accounts for 53% of the global copper reserves; the sum of the bauxite reserves of Guinea, Australia, and Brazil accounts for 58% of the global bauxite reserves.Although the minerals in these areas are very rich, with the increase of mining intensity and scale, the resource grade and mining grade have declined. A large number of tailings stacking and layer-rock stripping have brought new environmental pollution and potential safety hazards. Advanced applications Equipment, improving mining and dressing techniques, reducing tailings stockpiling and environmental pollution, and increasing mineral utilization have become the first choice for mining development.

In countries rich in metal mineral resources, tailings stockpiles mainly come from weakly magnetic and non-magnetic debris. The most effective way to reduce tailings stock is to use advanced equipment to maximize the weakly magnetic and other valuable materials. The materials are sorted out to improve the utilization rate of minerals.

The intelligent oil-cooled vertical ring high-gradient magnetic separator developed by Shandong Huate Magnetoelectricity has the characteristics of high field strength, large processing capacity, intelligent adjustment, and fault self-diagnosis in the separation of weak magnetic materials and comprehensive recovery of tailings. The core product in the equipment truly realizes unattended and remote control, and can be widely used in wet separation of various weakly magnetic minerals such as hematite, limonite, manganese ore, ilmenite, and quartz, feldspar, sauria Iron removal and purification of non-metallic minerals such as quarry. At present, it has been exported in batches to Australia, Austria, Brazil, South Africa, Malaysia, the Philippines, India and other parts of the world.

The intelligent oil-cooled vertical ring high-gradient magnetic separator manufactured according to Australian standards successfully rolled off the line

Huate Magnetoelectric Intelligent Oil-cooled Vertical Ring High Gradient Magnetic Separator has the following characteristics:

1

International leading large-flow oil-water heat exchange cooling system

In the process of converting electrical energy into magnetic energy, the coils of the vertical ring high gradient magnetic separator will release a large amount of heat energy. At present, the cooling method of the conventional high gradient magnetic separator coil is internal water cooling. Due to the influence of water quality, during the use of the equipment , The water in the excitation wire is easy to form scale due to the increase in temperature, which will cause blockage, which affects the heat dissipation effect. It needs to be cleaned regularly. The failure rate is high and the coil life is short. The externally cooled oil-water heat exchange cooling system developed by Huate Magneto adopts oil-immersed coils and a large flow of external circulating oil-water heat exchange heat dissipation. The use of flushing water takes away the heat of the coil, which can greatly improve the heat dissipation capacity of the magnetic separator coil. The heat dissipation problem of the high-field-strength magnetic separator coil opens up a new way to solve the separation of low-grade, fine-grained, weakly magnetic metal ores and the purification of non-metallic ores.

2

Advanced sorting liquid level automatic control system

The level of the liquid level in the sorting chamber is one of the important factors that affect the sorting index. The conventional vertical ring adopts manual adjustment, which is labor intensive and has many human factors, and the sorting index is poor in stability. The intelligent liquid level automatic control system developed by Huate, through the equipment liquid level communication device, liquid level sensor information feedback device, and gas-controlled ore discharge execution system, dynamically detects the liquid level fluctuation status in real time and can be adjusted online in real time, always maintaining the best score Select the level.

3

Advanced vibration sensing detection system

The driving parts such as the equipment swivel and pulsation device are equipped with vibration sensing devices to monitor the operation status of the equipment in real time and transmit the data to the remote monitoring center to diagnose abnormal information and fault points of the equipment in advance to ensure that the equipment is running in a good state.

4

Automatic filtration and sewage system for unloading process water

The cleanliness of the unloading process water is the key to ensuring the smooth unloading of the media box. The Huate intelligent vertical ring adopts a cyclone sedimentation anti-pan filter, and is equipped with a pressure feedback device and a sewage discharge execution system. When the sewage reaches a certain limit, Through information feedback, the filter automatically discharges sewage, always keeps the flushing water quality clean, ensures that the outlet hole of the flushing water pipe is not blocked, and realizes the best unloading efficiency of the media box.

5

Perfect temperature sensing detection and early warning system

It has a complete temperature warning system. The coil part and the water inlet and outlet of the heat exchanger are equipped with temperature sensing devices to detect the working temperature of the equipment in real time and feedback the information to the centralized control center. When the equipment has a heat dissipation failure or other problems, the temperature reaches the specified upper limit. The early warning system will give an alarm and stop working to ensure the safe operation of the equipment.

6

Safe leak alarm device

The working state of the oil-cooled vertical ring high gradient magnetic separator is that the cooling water pressure is high and the coil cooling oil pressure is low. When the cooling medium leaks during long-term use, the fluid information can be transmitted to the early warning device in advance to ensure the long-term safety of the excitation coil and the heat exchanger.

7

Perfect automatic lubrication system

Using advanced lubrication intermediate wheel and automatic control lubrication system, according to the amount of grease at different points, each lubrication point is automatically and quantitatively lubricated without stopping, which improves the operation rate of the equipment.

8

Leading DCS distributed control system

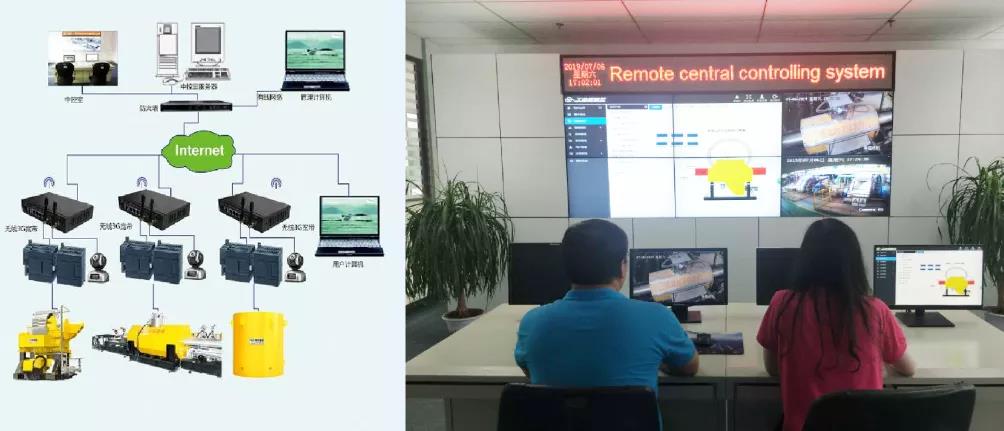

The application of the Internet of Things technology can transmit the field information and operating parameters of the vertical ring high gradient magnetic separator to the remote central control room in real time through sensors, forming a DCS distributed control system for remote equipment, which can dynamically display the operating parameters of the equipment in real time. Perform data analysis, fault diagnosis and processing of the equipment used to realize unattended and intelligent operation of the equipment mine.

The intelligent oil-cooled vertical ring high gradient magnetic separator has a complete separation monitoring system and process supporting control system. During the material separation process, there are also supporting control measures for the slurry flow and concentration process. Online detection and information feedback, adjust the processing capacity of the vertical ring in time, ensure the stability of the pulp output parameters, and provide a basic guarantee for achieving stable sorting indicators.

The mass export application of the intelligent oil-cooled vertical ring high gradient magnetic separator indicates that my country’s mineral processing technology and equipment has entered the forefront of the world, especially for the separation of weak magnetic materials from global metal mines, tailings re-separation, and non-metallic mine removal. Iron purification has played a vital role, improving the mineral recovery rate and product quality, reducing tailings stacking and environmental pollution, further improving the service life of mines, promoting technological progress in the industry, and effectively utilizing global mineral resources. Environmental protection plays an active role in promoting, and will also bring huge economic and social benefits to the green development of smart mines.

Application Cases of Australian Hematite Tailings Reconcentration

Application case of an ilmenite magnetic separation project in Chengde, Hebei

South Africa Chromite Tailings Reconcentration Application Case

Application case of a wet pre-selection project of a hematite mine in Anshan City, Liaoning Province

Austrian quartz sand removal and purification application case

Austrian quartz sand removal and purification application case

Malaysia hematite separation application case

Post time: Sep-28-2021