Kaolin has abundant reserves in my country, and the proven geological reserves are about 3 billion tons, mainly distributed in Guangdong, Guangxi, Jiangxi, Fujian, Jiangsu and other places. Due to the different geological formation reasons, the composition and structure of kaolin from different producing areas are also different. Kaolin is a 1:1 type layered silicate, which is composed of an octahedron and a tetrahedron. Its main components are SiO2 and Al203. It also contains a small amount of Fe203, Ti02, MgO, CaO, K2O and Na2O, etc. ingredient. Kaolin has many excellent physical and chemical properties and process characteristics, so it is widely used in petrochemicals, papermaking, functional materials, coatings, ceramics, water-resistant materials, etc. With the advancement of modern science and technology, the new uses of kaolin are constantly expanding, and they are beginning to penetrate into the high, precise and cutting-edge fields. Kaolin ore contains a small amount (usually 0.5% to 3%) of iron minerals (iron oxides, ilmenite, siderite, pyrite, mica, tourmaline, etc.), which color the kaolin and affect its sintering Whiteness and other properties limit the application of kaolin. Therefore, the analysis of the composition of kaolin and the research on its impurity removal technology are particularly important. These colored impurities usually have weak magnetic properties and can be removed by magnetic separation. Magnetic separation is a method of separating mineral particles in a magnetic field by using the magnetic difference of minerals. For weakly magnetic minerals, a high-gradient strong magnetic field is required for magnetic separation.

Structure and working principle of HTDZ high gradient slurry magnetic separator

1.1 The structure of the electromagnetic slurry high gradient magnetic separator

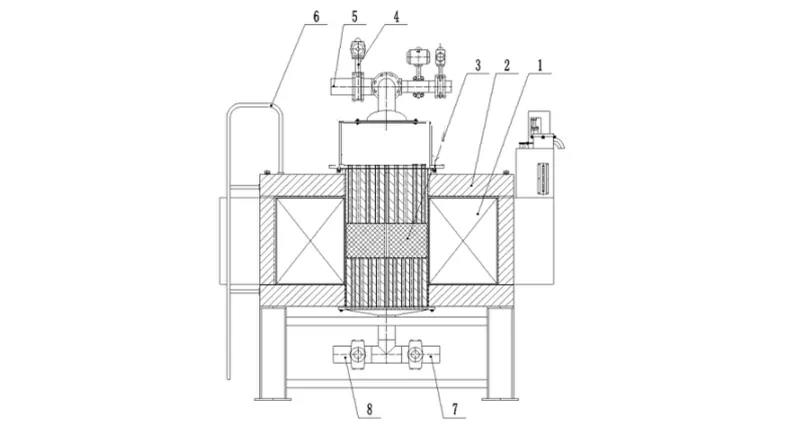

The machine is mainly composed of frame, oil-cooled excitation coil, magnetic system, separation medium, coil cooling system, flushing system, ore inlet and discharge system, control system, etc.

Figure 1 Structure diagram of high gradient magnetic separator for electromagnetic slurry

1- Excitation coil 2- Magnetic system 3- Separating medium 4- Pneumatic valve 5- Pulp outlet pipeline

6-Escalator 7-Inlet pipe 8-Slag discharge pipe

1.2 Technical characteristics of HTDZ electromagnetic slurry high gradient magnetic separator

◎Oil cooling technology: Fully sealed cooling oil is used for cooling, heat exchange is carried out using the principle of oil-water heat exchange, and a large-flow disc transformer oil pump is adopted. The cooling oil has a fast circulation speed, strong heat exchange capacity, low coil temperature rise, and high magnetic field strength.

◎Current rectification and current stabilization technology: Through the rectifier module, stable current output is realized, and the excitation current is adjusted according to the characteristics of different materials to ensure stable magnetic field strength and achieve the best beneficiation index.

◎Large cavity armored high-performance physical magnet technology: Use iron armor to wrap the hollow coil, design a reasonable electromagnetic magnetic circuit structure, reduce the saturation of the iron armor, reduce magnetic flux leakage, and form high field strength in the sorting cavity.

◎Solid-liquid-gas three-phase separation technology: The material in the separation chamber is subjected to buoyancy, own gravity, and magnetic force to achieve a proper beneficiation effect under proper conditions. The combination of unloading water and high air pressure makes the medium flushing cleaner.

◎New spiky stainless magnetic conductive and magnetic material technology: the sorting medium adopts steel wool, diamond-shaped media mesh, or the combination of steel wool and diamond-shaped media mesh. This medium combines the characteristics of the equipment, and the research and development of wear-resistant high-permeability stainless steel, The magnetic field induction gradient is large, it is easier to capture weak magnetic minerals, the remanence is small, and the medium is easier to wash when the ore is discharged.

1.3 Equipment principle analysis and magnetic field distribution analysis

1.3.1 The sorting principle is: In the armored coil, a certain amount of magnetically conductive stainless steel wool (or expanded metal) is placed. After the coil is excited, the magnetically conductive stainless steel wool is magnetized, and a highly uneven magnetic field is generated on the surface, namely High-gradient magnetizing magnetic field, when the paramagnetic material passes through the steel wool in the sorting tank, it will receive a magnetic field force proportional to the product of the applied magnetic field and the magnetic field gradient, and it will be adsorbed on the surface of the steel wool, instead of the non-magnetic material passing the magnetic field directly. It flows into the non-magnetic product tank through the non-magnetic valve and pipeline. When the weakly magnetic material collected by the steel wool reaches a certain level (determined by the process requirements), stop feeding the ore. Disconnect the excitation power supply and flush the magnetic objects. The magnetic objects flow into the magnetic product tank through the magnetic valve and pipeline. Then carry out the second homework, and repeat this cycle.

1.3.2 Magnetic field distribution analysis: Use advanced finite element software to quickly simulate the magnetic field distribution cloud map, shorten the cycle of design and analysis; adopt optimized design to reduce equipment power consumption and reduce user costs; discover potential problems before product manufacturing , Increase the reliability of products and projects; simulate various test schemes, reduce test time and expenses;

Mineral movement characteristics

2.1 Material movement analysis

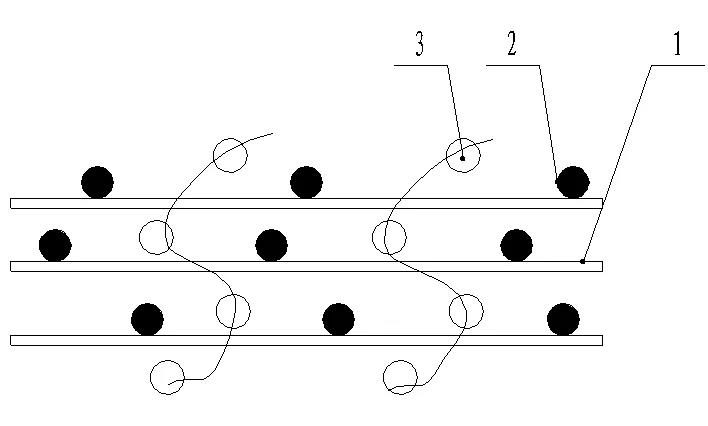

The HTDZ high gradient magnetic separator is suitable for the lower feeding when sorting kaolin. The equipment adopts multi-layer stainless steel wool (or expanded metal) as the sorting medium, so that the trajectory of the ore particles is irregular in the vertical and horizontal directions. The curve movement of the mineral particles is shown in Figure 1. Therefore, extending the running time and distance of the minerals in the separation area is helpful for the full adsorption of weak magnets. In addition, the slurry flow rate, gravity and buoyancy during the separation process interact with each other. The effect is to keep the ore particles in a loose state at all times, reduce the adhesion between ore particles, and improve the efficiency of iron removal. Obtain a good sorting effect.

Figure 4 Schematic diagram of mineral movement

1. Media network 2. Magnetic particles 3. Non-magnetic particles。

2. The nature of raw ore and the basic process of beneficiation

2.1 The properties of a certain kaolin mineral material in Guangdong:

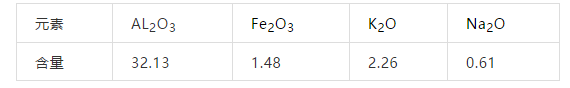

The gangue minerals of kaolin in a certain area in Guangdong include quartz, muscovite, biotite and feldspar, and a small amount of red and limonite. Quartz is mainly enriched in the +0.057mm grain size, the content of mica and feldspar minerals is enriched in the middle grain size (0.02-0.6mm), and the content of kaolinite and a small amount of dark minerals gradually increases as the grain size decreases. , Kaolinite starts to be enriched at -0.057mm, and is obviously enriched at -0.020mm size.

Table 1 Multi-element analysis results of kaolin ore%

2.2 The main beneficiation conditions applicable to the experimental exploration of small sample

The main factors that affect the magnetic separation process of the HTDZ high gradient slurry magnetic separator are the slurry flow rate, the background magnetic field strength, etc. The following two main conditions are tested in this experimental study.

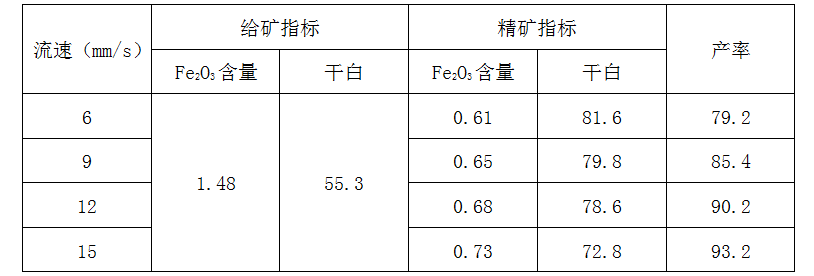

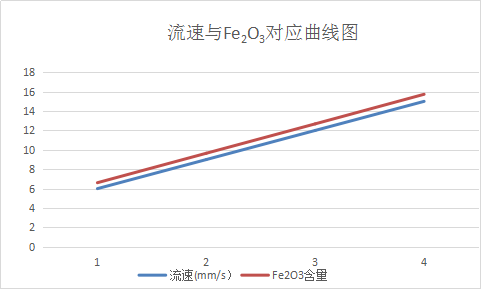

2.2.1 Slurry flow rate: When the flow rate is large, the concentrate yield is higher, and its iron content is also high; when the flow rate is low, the concentrate iron content is low, and its yield is also low. The experimental data is shown in Table 2

Table 2 Experimental results of slurry flow rate

Note: The slurry flow rate test is carried out under the conditions of a background magnetic field of 1.25T and a dispersant dosage of 0.25%.

Figure 5 Correspondence between flow rate and Fe2O3

Figure 6 Correspondence between flow velocity and dry white。

Considering the beneficiation cost comprehensively, the slurry flow rate should be controlled at 12mm/s.

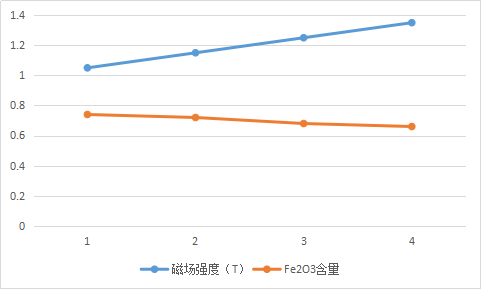

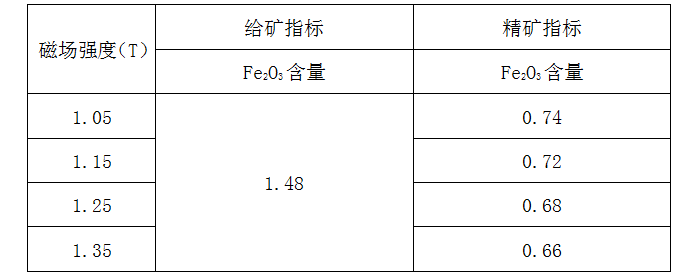

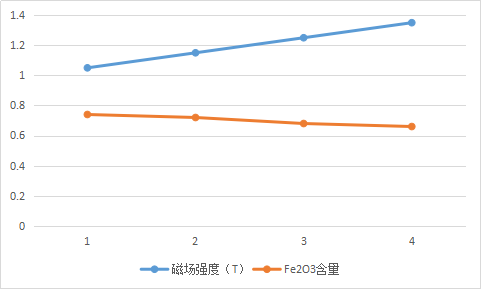

2.2.2 Background magnetic field: The background magnetic field intensity of the slurry magnetic separator is consistent with the law of the iron removal index of kaolin magnetic separation, that is, when the magnetic field intensity is high, the concentrate yield and iron content of the magnetic separator are both low, and the iron removal rate is relatively low. High, good effect of removing iron.

Table 3 Experimental results of background magnetic field

Note: The background magnetic field test is carried out under the conditions of a slurry flow rate of 12mm/s and a dispersant dosage of 0.25%.

Because the higher the background magnetic field intensity, the greater the excitation power, the higher the energy consumption of the equipment, and the higher the unit production cost. Considering the cost of beneficiation, the selected background magnetic field is set at 1.25T.

Figure 7 Correspondence between magnetic field strength and Fe2O3 content。

2.3 Basic process selection of magnetic separation

The main purpose of kaolin ore beneficiation is to remove iron and purify. According to the magnetic difference of each mineral, the use of high gradient magnetic field to remove iron and purify kaolin is effective, and the process is simple and easy to implement in industry. Therefore, a high-gradient slurry magnetic separator, one coarse and one fine, is used as the sorting process.

Industrial production

3.1 Kaolin industrial production process

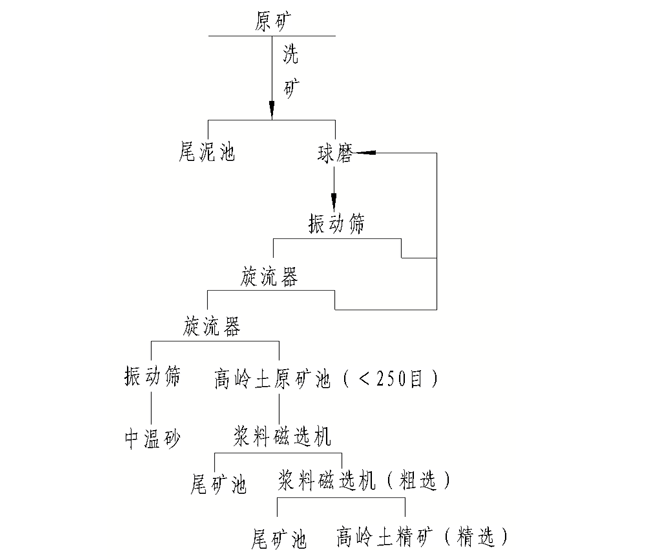

For iron removal from kaolin ore in a certain area in Guangdong, HTDZ-1000 series combination is used to form a coarse-fine magnetic separation process. The flow chart is shown in Figure 2.

3.2 Industrial production conditions

3.2.1 Material classification: main purpose: 1. Separate impurities such as quartz, feldspar and mica in kaolin in advance through a two-stage cyclone, reduce the pressure of subsequent equipment, and classify the particle size to meet the requirements of subsequent equipment. 2. Since the separation medium of the slurry magnetic separator is 3# steel wool, the particle size must be below 250 mesh to ensure that there are no particles remaining in the steel wool medium to prevent the steel wool medium from blocking the steel wool medium, affecting the beneficiation index and medium washing And the processing capacity of the equipment, etc.

3.2.2 Operating conditions of magnetic separation: the process flow adopts one coarse and one fine test and one coarse and one fine open circuit process. According to the sample experiment, the background field strength of the high-gradient slurry magnetic separator for roughing operation is 0.7T, the high-gradient magnetic separator for selection operation is 1.25T, and an HTDZ-1000 magnetic separator for roughing slurry is used. Equipped with a HTDZ-1000 selected slurry magnetic separator.

3.3 Industrial production results

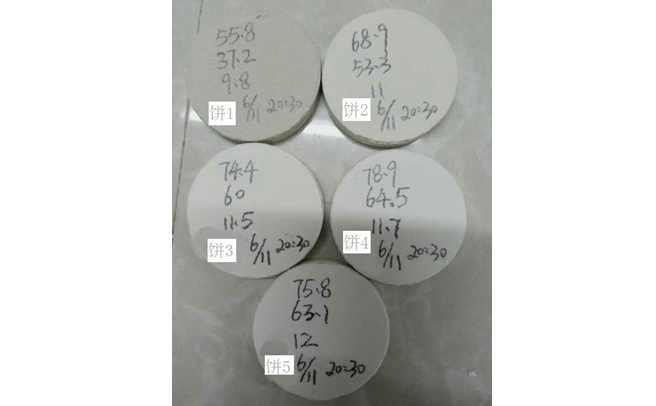

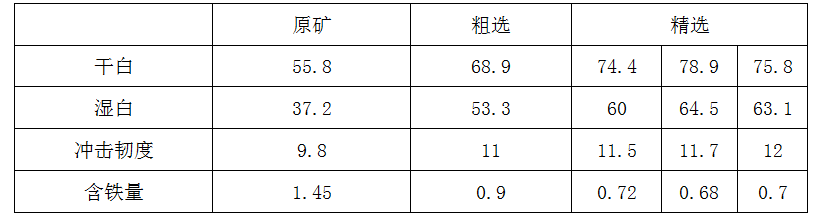

The industrial production of kaolin for iron removal in a certain place in Guangdong, the product sample cake produced by the HTDZ slurry high gradient magnetic separator is shown in Figure 3, and the data is shown in Table 2.

Cake 1: It is the raw ore sample cake that enters the coarse separation slurry magnetic separator

Pie 2: Roughly selected sample pie

Pie 3, Pie 4, Pie 5: Selected samples

Table 2 Results of industrial production (results of sampling and breaking cakes at 20:30 on November 6th)

Figure 3 A sample cake produced by kaolin in a certain place in Guangdong

The production results show that the Fe2O3 content of the concentrate can be reduced by about 50% through two high-gradient magnetic separation of the slurry, and a good iron removal effect can be obtained.

应用案例

Post time: Mar-27-2021