In the process of magnetic separation of magnetite, due to magnetic agglomeration, it is easy to produce “magnetic inclusions” and “non-magnetic inclusions”, which seriously affect the grade of concentrates.The fully automatic electromagnetic washing and concentrating machine independently developed by Walt is a new generation of weak magnetic field magnetic separation equipment. It comprehensively considers the comprehensive force fields such as magnetic force, gravity, buoyancy, centrifugal force, etc. Combined, the operating parameters are automatically adjusted according to the properties of the ore, which can effectively reduce the content of impurities such as silicon, phosphorus, and sulfur in the magnetic ores, and obtain high-grade magnetite concentrates and intermediate products such as concentrates in the magnetic separation process, which are qualified in advance. The final concentrate is suitable for the beneficiation operation of the magnetite concentrator, which opens up a new way for my country’s iron concentrate to implement the strategy of “improving and reducing impurities”.

Working principle

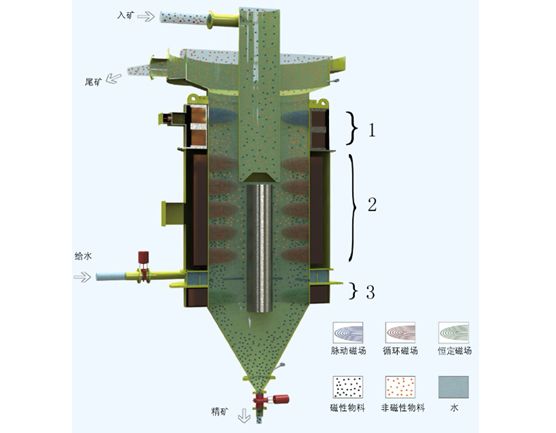

The ore is fed into the middle and upper part of the elutriation machine by the ore feeding hopper and the ore feeding pipe, and is washed away by the flushing water. Between the two coils and when the coil is powered off, since the downward magnetic force is greatly weakened, it is sheared and dispersed by the high-speed rotating upward water flow, so that the single gangue, ore slime and conjoined organisms mixed in it, especially the poor conjoined organisms. The rushing belt is upward, and under the action of relatively strong rotating upward water flow, it rises to the overflow edge and is discharged to become tailings mainly composed of contiguous bodies.

The working principle of electromagnetic panning selection machine

The magnetic minerals in the ore are magnetized by the magnetic field generated by the electrified coil, and the magnetized magnetic ore particles become magnetic dipoles, and many magnetic dipoles attract each other to form magnetic chains.When the coil is powered off, the instantaneous flux linkage of the power off is fully dispersed by axial shearing under the action of high-speed rotating and rising water flow.The above process is repeated when the next coil is energized and de-energized. This process is carried out for many times, so that the magnetic material can be selected many times in the elutriation machine to obtain high-grade magnetite concentrate, and at the same time, the content of impurities such as SiO2 is also reduced.

The control process of the washing machine

The elutriation machine adopts two-impulse control, that is, the overflow concentration and the underflow concentration are the control targets.The overflow concentration is controlled by the magnitude of the magnetic field force, and the underflow concentration is controlled by the opening of the bottom valve.In the control system, by setting the target values of overflow concentration and underflow concentration, the control system adopts an intelligent control algorithm to control the magnetic field force and the opening of the bottom valve to keep the target value within a certain working range.

When the ore feeding amount is unstable, the control system will automatically adjust the bottom valve according to the change of the underflow concentration inside the elutriation machine, so that the magnetic medium inside the elutriation machine remains unchanged and maintains a stable sorting environment;When the water supply is unstable, the control system adjusts the intensity of the magnetic field according to the change of the overflow concentration of the washing machine to ensure the stability of the concentrate index.

The automatic electromagnetic panning and selecting machine adopts advanced PID-automatic optimization control method, which does not need manual duty and always works in the best state.Using the Internet of Things technology, the operating parameters are transmitted to the remote cloud platform, and electronic files are established for the equipment to manage the entire life cycle;Our company’s mineral processing experts can remotely adjust the mineral processing parameters of the washing machine through the remote monitoring platform to better serve users.

Application case of electromagnetic panning selection machine

Post time: Mar-21-2022