Due to the shortage of power supply, many provinces across the country have successively issued power ration notices, which aroused heated discussions. Under the background of the energy crisis, it has brought a huge impact on the economic development of mining enterprises. Green and low-carbon is the only way to sustainable development. How? Using high-tech and technological innovation to give new momentum to traditional industries, and to implement the awareness of energy conservation and emission reduction in daily work and life is an urgent problem to be solved, and it is also an endogenous need of China’s economic transformation.

As basic functional materials, non-metallic minerals are widely used in industries such as information technology, high-end equipment, new materials, new energy, energy saving and environmental protection. The rapid development of the non-metallic mineral industry has strongly promoted the development of advanced structural materials and functional materials. And the rapid development of technology and economy. Non-metallic mineral materials generally require high purity, and the impurity content often determines the quality level of the product, especially the iron-titanium content. In the processing of non-metallic minerals, iron and titanium removal operations are generally required.

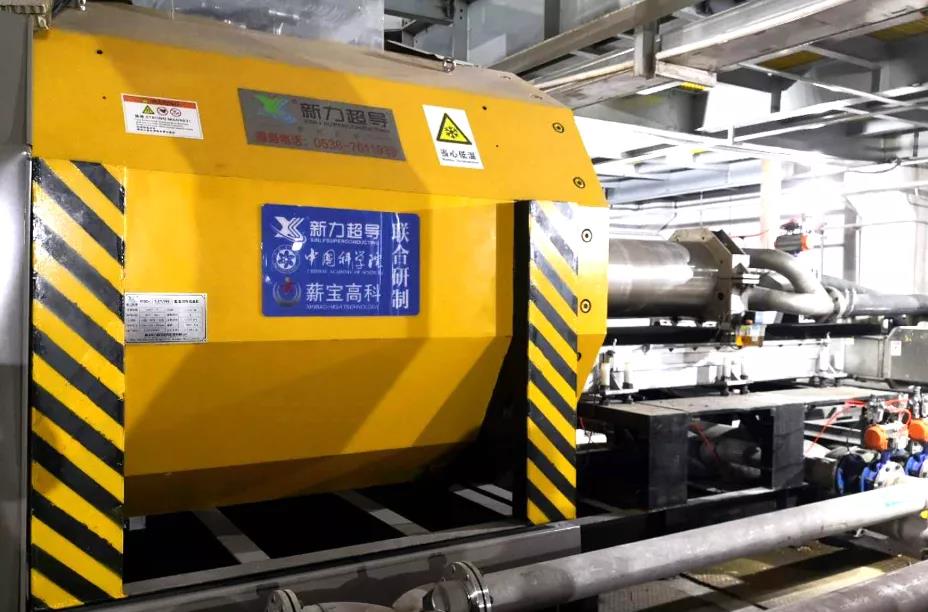

At present, the iron removal and purification methods of non-metallic minerals mainly include magnetic separation, flotation, gravity separation, electrical separation, chemical separation, friction separation, and photoelectric sorting.With the implementation of the “two carbon targets” and the need for efficient utilization of mineral resources, magnetic separation has become the main method for removing impurities from non-metallic ores, especially when dealing with high-value, high-purity non-metallic ores. The highest magnetic field is limited by physical limitations, and the low-temperature superconducting magnetic separator has the advantage of a natural high magnetic field.Iron and titanium impurities in general non-metallic minerals have the characteristics of weak magnetism, fine particle size, and difficult removal. Aiming at the technical problems existing in conventional magnetic separators for iron removal, Weifang Xinli Superconducting Magnetoelectric Technology Co., Ltd. has developed and produced the CGC series of low-temperature superconducting magnetic separators, covering equipment of various calibers such as industrial machines and laboratory models. The equipment has the advantages of low operating cost, energy saving, high equipment operation rate and long service life. It can be applied to the purification of fine-grained non-metallic minerals such as kaolin and rare earths, and can effectively reduce the content of harmful impurities such as iron and titanium.

Xinli superconducting cryogenic superconducting magnetic separator has the following characteristics

01Low energy consumption

Using low-temperature superconducting technology, the coil works at a low temperature of 4.2K (-268.8°C). At this time, the coil resistance is zero, and the superconducting state is realized after energization. The refrigeration system only needs to maintain the superconducting magnet in this low temperature state, which saves 90% of electricity compared with the normal conductance magnet, has a significant operating cost advantage, and is lower in carbon and green.

02 zero volatilization of liquid helium

The closed-cycle refrigeration technology is used for the first time at home and abroad, using a refrigerator for continuous refrigeration, closing the gas-liquid two-phase cycle of helium, so that helium does not volatilize to the outside of the magnet, and the total amount of liquid helium remains unchanged. No need to replenish within 2-3 years Liquid helium greatly reduces maintenance costs.

03The magnetic field can be adjusted arbitrarily

The magnetic field generated by superconducting has high intensity and large gradient. For different non-metallic minerals, the magnetic field intensity can be selected from 0 to the highest field according to the properties of minerals, composition, etc., without loss of helium.

04High work efficiency

The double-cylinder alternate sorting and flushing can run continuously under the excitation state, and the production efficiency is as high as about 75%.

05Long service life

Superconducting coils operate in a low-temperature environment with a single helium, and the degree of thermal aging is very low, and the life of superconducting coils is longer than that of normal-conducting coils.

06Perfect DCS distributed control

The application of the Internet of Things technology can transmit the information and operating parameters of the cryogenic superconducting magnetic separator to the remote central control room in real time through sensors, forming a DCS distributed control system for remote equipment, which can dynamically display the operating parameters of the equipment in real time. Use equipment for data analysis, fault diagnosis and processing to realize unattended and intelligent operation of equipment.

IoT 5G remote monitoring platform

The mineral composition of a kaolin mine in Guangdong is kaolin, quartz, mica minerals and a small amount of potash feldspar, hematite, and ilmenite. By analyzing the characteristics of iron, titanium and other impurity minerals in the original ore of the plant, we use a low-temperature superconducting magnetic separator as the finished product control equipment.

The production results show that after high-gradient magnetic separation, the iron content decreases from 0.85% to 0.51%, the iron removal rate can reach 40.0%, and the calcination whiteness is also significantly improved, reaching 81.1. The low-temperature superconducting magnetic separator has obvious effect on removing iron and titanium from kaolin, and the quality is stable.

The site of the China-German Magnetoelectric and Intelligent Mineral Processing Key Laboratory

The industry application and promotion of low-temperature superconducting magnetic separators at home and abroad indicate that my country’s mineral processing technology and equipment have reached the world’s leading level, especially for the separation of high-quality kaolin, the purification of rare earth ore and the magnetic separation of other fine-grained minerals. It plays an important role in improving the recovery rate of minerals and product quality, and will play a positive role in promoting the advancement of the industry’s deep processing technology and the sustainable development of green mines. It will also bring huge economic, ecological and social benefits to the green development of smart mines. benefit.

Guangdong Huaiji customer use site

Fujian customers use the scene

Inner Mongolia customer application site

Two superconducting magnetic separators used by Czech customers

Guangxi customer superconducting magnetic separator use site

Laboratory type superconducting magnetic separator use site

Weifang Xinli Superconducting Magnetoelectric Technology Co., Ltd.

Weifang Xinli Superconducting Magnetoelectric Technology Co., Ltd. was established in Weifang High-tech Zone in 2009. It is a wholly-owned subsidiary of Shandong Huate Magnetoelectric Technology Co., Ltd., a high-tech enterprise in Shandong Province, and a strategic alliance for magnetoelectric and cryogenic superconducting magnet innovation. Unit, Shandong Province Specialized and Special New Enterprise, Weifang City Hidden Champion Enterprise. The company has a strong technical force and has a national post-doctoral research station. It is a leading (cultivating) enterprise in the high-end equipment manufacturing industry in Shandong Province. The company is mainly engaged in research and development of superconducting technologies such as medical superconducting magnetic resonance (MRI) and industrial superconducting magnetic separation equipment, and realizes industrialization. It is the only superconducting magnet and complete machine that integrates R&D and production in the north of the Yangtze River. Equipment manufacturing enterprises.

The technical performance of the company’s main products has reached the international leading level, and the superconducting iron separator and superconducting magnetic separator have filled the domestic gap. The 1.5T MRI superconducting magnet series products were listed in the national “Twelfth Five-Year” science and technology support plan and the “Shandong Province Independent Innovation Achievement Transformation Major Special Project”, and the 3.0T MRI superconducting magnet was listed in the “Shandong Province Key R&D Program Project”. The 7.0T MRI life-metabolism superconducting magnet project was included in the “Thirteenth Five-Year” scientific and technological development plan of Shandong Province; the industrial superconducting magnetic separation equipment was included in the national “Twelfth Five-Year” science and technology support plan and the “Shandong Province National Independent Innovation” Key Projects in the Demonstration Zone”.

Post time: Nov-04-2021