【01 Overview】

HUATE MAGNET

China's iron ore resources are rich in reserves and various types, but there are many lean ore, less rich ore, and finely embedded grain size. There are very few ore that can be directly used, and a large amount of ore needs to be processed by beneficiation. For a long time, there have been more and more difficult beneficiation in the selected ores, the beneficiation ratio is getting bigger and bigger, the process and equipment are getting more and more complicated, especially the grinding cost is showing an increasing trend. Therefore, it is very important to reduce the energy consumption of the grinding process in the beneficiation process. At present, the dressing plants generally adopt measures such as more crushing and less grinding, pre-selection and discarding before grinding, etc., which have achieved remarkable results.

In areas with shortage of water resources, the water for mining development cannot be guaranteed, which makes the wet separation of minerals unfeasible. Therefore, in these areas, the dry pre-selection method will be considered first for waste disposal.

The fine crushing and dry polishing with a particle size of 20-0 mm, and the dry polishing of the crushed products of the high-pressure roller mill which are widely used at present, the structure of the selected equipment is different. The magnetic separator has the characteristics of saving installation space, large processing capacity, high scrap rate and high recovery rate, and has achieved good results in practical applications.

[02 Structural principle and use effect]

HUATE MAGNET

The three-drum combined dry pre-selection machine usually has two layouts: one roughing and two sweeping, and one roughing and two finishing. The magnetic pole layout structure is designed according to the requirements of mineral sorting indicators, taking into account the rejection rate and recovery rate, and through simulation analysis, one-to-one design.

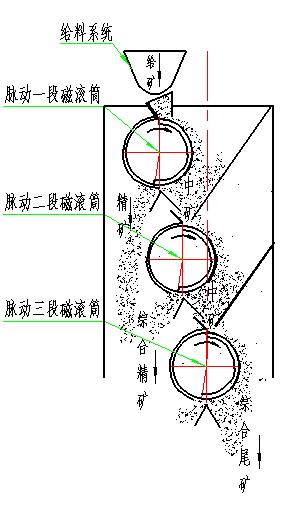

1. Working principle of one rough and two sweeps

The equipment enters the ore through the feeding device. The ore is separated by the first drum to take out part of the concentrate. The tailings of the first tube enter the second tube for sweeping, the tailings of the second tube enter the third tube and the tailings of the third tube enter the third tube. For the final tailings, the concentrates of the first, second and third barrels are combined into the final concentrate. The working principle of one rough two scan is shown in Figure 1.

▲Figure 1 Schematic diagram of the working principle of one rough and two sweeps

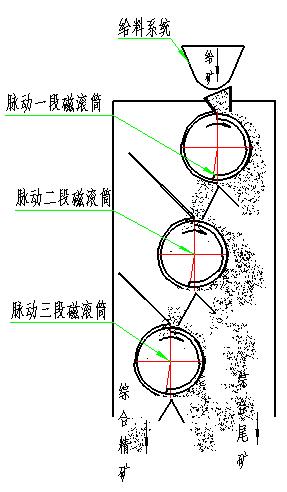

2. The working principle of one rough and two fine

The equipment enters the ore through the feeding device. After the ore is separated by the first drum, the concentrate enters the second barrel for further separation, and the concentrate in the second barrel enters the third barrel for separation. The concentrate in the third barrel is the final concentrate. The tailings of the second and third cylinders are combined into the final tailings. The working principle of one coarse and two fine is shown in Figure 2.

▲ Figure 2 Schematic diagram of the working principle of one coarse and two fine

3 .Application site of MCTF series three-drum pulsating dry magnetic separator

▲Figure 3 Application site of 3MCTF three-drum pulsating dry magnetic separator with roller feeding device

The customer in the picture above uses a three-drum 1030 dry pre-separator on site. The diameter of the drum is 1000mm and the length is 3000mm. The process layout is one roughing and two sweeping. The magnetic iron is 0.6%, and the scrap rate is more than 30%, which achieves the expected effect.

【03 Manufacturing site】

HUATE MAGNET

▲Manufacturing site of three-drum pulsating dry magnetic separator

Scope of technical services of Huate Mineral Processing Engineering Design Institute

①Analysis of common elements and detection of metal materials.

②Preparation and purification of non-metallic minerals such as English, long stone, fluorite, fluorite, kaolinite, bauxite, leaf wax, and baryrite.

③The beneficiation of black metals such as iron, titanium, manganese, chromium and vanadium.

④ Mineral beneficiation of weak magnetic minerals such as black tungsten ore, tantalum niobium ore, pomegranate, electric gas, and black cloud.

⑤ Comprehensive utilization of secondary resources such as various tailings and smelting slag.

⑥ There are ore-magnetic, heavy and flotation combined beneficiation of ferrous metals.

⑦Intelligent sensing sorting of metallic and non-metallic minerals.

⑧ Semi-industrialized continuous selection test.

⑨ Ultrafine powder processing such as material crushing, ball milling and classification.

⑩ EPC turnkey projects such as crushing, pre-selection, grinding, magnetic (heavy, flotation) separation, dry raft, etc.

Post time: Jul-25-2022