Pyrophyllite is a water-containing aluminosilicate mineral with pearl or grease luster. Commercial pyrophyllite does not have strict boundaries with talc and saponite. The chemical composition of pyrophyllite is similar to kaolin minerals, and both are water-containing aluminosilicate minerals. Pyrophyllite was first used as an industrial product for carving, as well as seals, stone pens, etc. With the development of modern industry, pyrophyllite is used as a filler for the production of refractory materials, ceramics, papermaking, pesticides, rubber, plastics and other industries, and it can also be used as raw materials such as glass fiber and white cement. Its application fields are relatively wide.

01

Ore properties and mineral structure

The chemical formula of pyrophyllite is Al2[SiO4O10](OH)2, in which the theoretical content of Al2O3 is 28.30%, SiO2 is 66.70%, H2O is 5.0%, Mohs hardness 1.25, density 2.65g/cm3, melting point 1700°c, It is white, gray, light green, yellow-brown and other colors, pearl or grease luster, tough, slippery, opaque or translucent, white streaks, and has good heat resistance and insulation.

Pure pyrophyllite mineral aggregates are rare in nature, and are generally produced from similar mineral aggregates, and they are also earthy and fibrous. The main symbiotic minerals are quartz, kaolin, and diaspore, followed by pyrite, chalcedony, opal, sericite, illite, alunite, hydromica, rutile, andalusite, kyanite, corundum, and dickite Wait.

02

Application fields and technical indicators

Pyrophyllite is widely used in the fields of sculpture, ceramics, glass, rubber, plastics, papermaking, refractory materials, and synthetic diamonds.

03

Mineral processing technology and processing technology

Beneficiation and purification

①, crushing and grinding

The crushing and grinding of pyrophyllite has two purposes: one is to prepare pyrophyllite and impurity mineral monomer dissociated powder materials for the purification operation of beneficiation, and the other is to directly deal with pyrophyllite whose purity can meet the requirements of the application field. Processed into powder products. Because the pyrophyllite is softer and the impurities are harder, it is very important to use selective crushing equipment for the beneficiation type.

②、Selection

The difference in the internal composition of pyrophyllite is more obvious in appearance. It mainly contains information such as lightness and color. It can be manually sorted out large impurity ore, or it can be sorted by photoelectric sorting machine such as near-infrared hyperspectral intelligent sorting machine.

③,Dense medium beneficiation

The density of pyrophyllite and impurity minerals is not much different, but after grinding, especially selective grinding, the primary particle size of different minerals is different, and the difference in hardness is more obvious. Hard minerals are often distributed in coarser grain sizes. According to these characteristics, theDense medium beneficiation method of suspension dispersion and sedimentation classification can be used for selection.

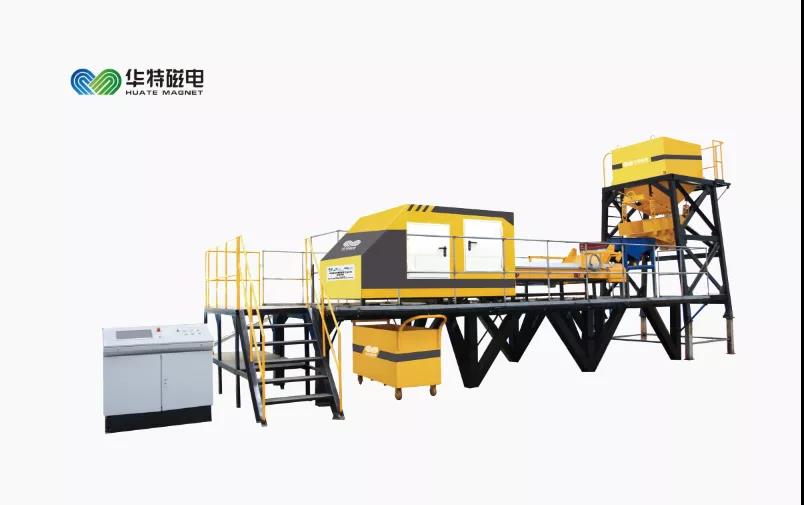

④ Magnetic separation

Most of the minerals in the pyrophyllite ore are not magnetically obvious, and the iron-containing impurities are weak. The mechanical iron produced during the crushing and grinding process can be separated by weak magnetic field. The existing iron oxide and iron silicate should be separated by vertical rings and electromagnetic pulp. High-gradient magnetic separator for high-gradient magnetic separation of materials.

⑤ Flotation

When the iron mineral impurities are sulfides, xanthates can be used for flotation to remove iron, when iron impurities are oxides, petroleum sulfonate can be used for flotation to remove iron, and pyrophyllite and quartz can be separated by fatty acids or amines. Used as a collector for flotation separation in alkaline or acidic media.

⑥. Chemical purification

For ore whose whiteness is poor and the physical beneficiation method is difficult to meet the quality index requirements, the reduction bleaching process can be used for chemical purification.

Superfine crushing

When pyrophyllite is used in papermaking, plastics, rubber, refractory materials and other fields, it needs to be superfinely crushed. At present, there are mainly two processes, dry and wet. The dry process mainly uses an ultra-fine grinding jet mill, and the wet process mainly uses a grinding stripper and a stirring mill.

Surface modification

The surface modification of pyrophyllite generally uses silane and titanate coupling agents. The surface modification of pyrophyllite powder has two methods: dry method and wet method.

Synthetic diamond

Pyrophyllite is chemically inert, resistant to high temperature and high pressure, has excellent electrical and thermal insulation, low shear strength and other properties, has ideal internal friction and solid transfer performance, and is widely used in modern ultra-high pressure technology. The most important ultra-high pressure transmission and sealing material in the superhard material industry. Pyrophyllite and alloy flakes, carbon flakes can obtain the required synthetic diamonds through high temperature, high pressure and chemical purification methods.

Post time: Jul-05-2021