In the vast land, there is a kind of treasure, it is dressed in red, hidden, it is hematite! The fire-like red, as if it were the most colorful in nature's palette, approaching it, you will find that its charm is far more than that.

Introduction

Hematite chemical composition for Fe2O3, is a hexagonal crystal system of oxide minerals, single crystals are often rhombic and plate-like, the aggregate form a variety of flaky, granular, oolitic, reniform, earthy, scaly, dense block and so on. The color is reddish brown, steel gray to iron black, etc., the stripes are cherry red, metallic to semi-metallic luster.

Hematite has several forms, according to their different forms and state of existence, they have different names: bright flash steel gray crystals called mirror iron ore, scale-like called mica hematite, loose earthy called ochre, many spherical agglomerates called renal iron ore, fibrous called pennant iron ore and so on.

Hematite deposits are extremely widespread, and the most prominent hematite deposits are produced by sedimentation. Hematite contains up to 70% iron and has large reserves, making it the most important raw material for iron ore used in steelmaking.

Application

1.The main raw material for smelting iron and steel, widely used in transportation, construction, furniture, industry and other fields, is the cornerstone of industrial civilization and human development.

2.A kind of natural mineral pigment, it is the earliest red mineral pigment applied in ancient times, its red color is pure and long-lasting, it is widely used in painting, sculpture and other fields.

3.It can be made into jewelry, it is usually dark red or reddish brown in color, with high hardness, and can be made into jewelry through cutting, polishing and other processing steps.

4.Hematite can be made into hematite bricks after processing. Hematite bricks have good refractory and heat insulation properties, and are widely used in the construction of high-temperature equipment and furnaces in the energy sector.

5.In addition to the above uses, hematite can also be used as medicine, cosmetic additives, fillers for plastic products, radium flash powder and so on.

Beneficiation Methods

Hematite is a kind of weakly magnetic iron ore, the beneficiation methods used are more, including re-election, flotation, strong magnetic separation, roasting magnetic separation and the joint process of several methods. At present, there are three typical beneficiation processes for hematite: continuous grinding-weak magnetic-strong magnetic, stage grinding-coarse and fine grading-reselection-magnetic separation and stage grinding-coarse and fine grading-reselection. Magnetic separation - re-election, if the concentrate grade is not up to the quality standard, anionic reverse flotation process can be used to improve the product.

Continuous Grinding-Weak Magnetic Separation-Strong Magnetic Separation Process

The process is characterized by:

◆ It has good adaptability to the process mineralogical characteristics of iron ore. Aiming at the feature that finely embedded iron ore needs fine grinding, the ore is ground by continuous grinding until the monomer is dissociated, and then the separation is carried out.

◆ The combined use of weak-strong magnetism realizes the best combination of the process. After continuous grinding, the weak magnetic separation process is used to select the qualified concentrate products from the magnetite with strong magnetism, and the tailings are then selected by the strong magnetic separation process to select the weakly magnetic iron oxide minerals by strong magnetism, and a large amount of tailings can be thrown off. If the qualified iron oxide concentrate is not obtained, anionic reverse flotation process can be used to further improve the quality of iron ore concentrate, so as to obtain high quality concentrate products.

◆This process has good process operation characteristics, and is conducive to the stability of beneficiation indexes due to its high concentrate grade and easy production control.

Stage grinding - coarse and fine classification - Gravity separation - Magnetic separation process

The process is characterized by:

◆ The raw ore is classified by hydrocyclone after primary grinding, and the coarse and fine grades are processed separately; the coarse grade adopts spiral chute re-election to obtain coarse qualified concentrate; the fine grade adopts weak-strong magnetic separation to ensure good separation index and high-grade fine concentrate; the re-elected ore is recovered by secondary grinding, and returned to the cyclone to be classified into strong magnetic separation operation.

◆Stage grinding and separation process is adopted. After one-stage grinding, the grading into the separation is realized under the coarser particle size, which reduces the phenomenon of over-grinding and alleviates the amount of minerals entering the second-stage grinding, meanwhile, the coarse-grained iron concentrate is easy to be filtered, which can effectively reduce the production cost.

The dissociation of ◆minerals in the process of grinding is random, the minerals that have reached the single dissociation under the condition of coarse grinding should be sorted out as early as possible, and the effective combination of coarse-grain level and fine-grain level beneficiation methods makes the process have the double features of economically reasonable and technologically advanced.

Stage grinding, Magnetic separation and Gravity separation

The process is characterized by:

◆ Adopting stage grinding process, reducing the amount of second stage grinding.

◆Adopting strong magnetic pre-tailing process can throw off a large amount of tailings, reduce the amount of ore in the subsequent operation, lower the production cost, and the grade of the ore entering the subsequent operation after strong magnetic tailing.

Strong magnetic output of iron ore concentrate can use the density difference, the use of re-election process will be similar to the hematite magnetization rate but the density of low iron silicate minerals effectively removed, and further improve the quality of iron ore concentrate.

Application and development of magnetic separator in hematite sorting

When hematite contains a small amount of magnetite, the use of cylinder magnetic separator will be strong magnetic magnetite selected in advance, and then the use of plate magnetic separator, LHGC vertical ring high gradient magnetic separator and other strong magnetic separation equipment, select different field strength, media, pulsation, concentration, roughing, sweeping, selection and other conditions of the beneficiation, can be low-grade weakly magnetic hematite material can be effectively selected, improve the grade of iron ore, not only solves the problem of low-grade hematite, but also improves the quality of iron ore, and also improves the efficiency of hematite separation. This not only solves the problems of development and utilization of low-grade hematite and environmental protection, but also significantly improves the utilization rate of the ore and economic benefits. With the progress of technology, such as high-efficiency magnetic separation technology, intelligent and automatic control, as well as energy-saving and environmental protection technology and large-scale application and promotion of equipment, the performance and efficiency of the magnetic separator has been significantly improved.

Changes in market demand, such as the demand for diversified ore processing, as well as the integration and upgrading of the mining industry, have promoted the continuous development of the strong magnetic separator technology, which in turn promotes the continuous development of the magnetic separator technology in the separation of hematite.

The increasingly strict environmental regulations and the popularization of the concept of circular economy make energy saving and environmental protection, comprehensive utilization of resources become an important development direction of the mining industry, and the strong magnetic separator is one of the key technologies to achieve this goal.

In summary, the application of strong magnetic separator in hematite industry not only improves the production efficiency and resource utilization, but also meets the requirements of environmental protection and sustainable development, so it has a broad market prospect and development potential.

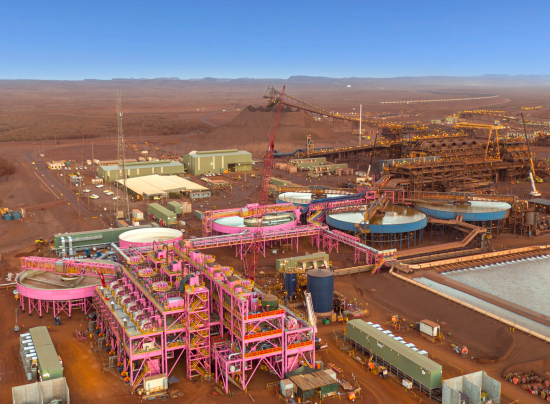

Application Cases

A hematite ore crushing, grinding to -200 mesh 66.5% fineness, through the CTB3000GS selection of magnetic iron, magnetic tail through the LHGC vertical ring 0.4T + 0.6T a coarse and a sweeping selection of iron oxide test process, to obtain the concentrate product.

Post time: Jun-06-2024