Chromite is an important material for smelting ferroalloys, stainless steel and precious alloys. The metallurgical industry uses about 60% of chromium, which is mainly used to produce alloy steel, especially stainless steel. At the same time, chromite is also widely used in the refractory industry, chemical industry and light industry.

Ore properties

There are more than fifty kinds of chromium-containing minerals found in nature, but the only chromium-containing minerals with industrial value are chromite, which are spinel (MgO, Al2O3), magnesia chromite (MgO, Cr2O3), and magnetite. (FeO, Fe2O3) and other solid solutions. Theoretically, the chemical formula of chromite is FeO, Cr2O3, containing 68% Cr2O3, 32% FeO, medium magnetic, density 4.1~4.7g/cm3, Mohs hardness 5.5~6.5, and the surface appearance ranges from black to dark brown. Gangue minerals mainly include olivine, serpentine and pyroxene, sometimes accompanied by a small amount of vanadium, nickel, cobalt and molybdenum group elements.

Processing Technology

China’s chromite resources are relatively poor, mainly concentrated in Tibet, Xinjiang, Inner Mongolia, Gansu and other provinces. Foreign chromite resources are mainly distributed in South Africa, Russia, Brazil, the United States and other countries. Chromite has the characteristics of high density, medium magnetism and coarse crystal particles. Generally, it is sorted by ore washing, weak magnetic separation, medium strong magnetic separation, gravity separation, flotation and other processes.

Washing method

It is suitable for coarse-grained chromite ore with high grade of raw ore and mainly clay-like fine mud as the impurities. Qualified coarse concentrate products can be selected by simple washing.

Magnetic separation

Chromite has medium magnetic properties and can be separated by dry or wet strong magnetic separation. The associated magnetite is first separated by weak magnetic, and then magnetically separated by CXJ or CFLJ, plate magnetic separator, vertical ring high gradient magnetic separator, etc. The equipment performs dry and wet beneficiation, and can select qualified concentrate products. The magnetic separation method has the advantages of large processing capacity and stable indicators.

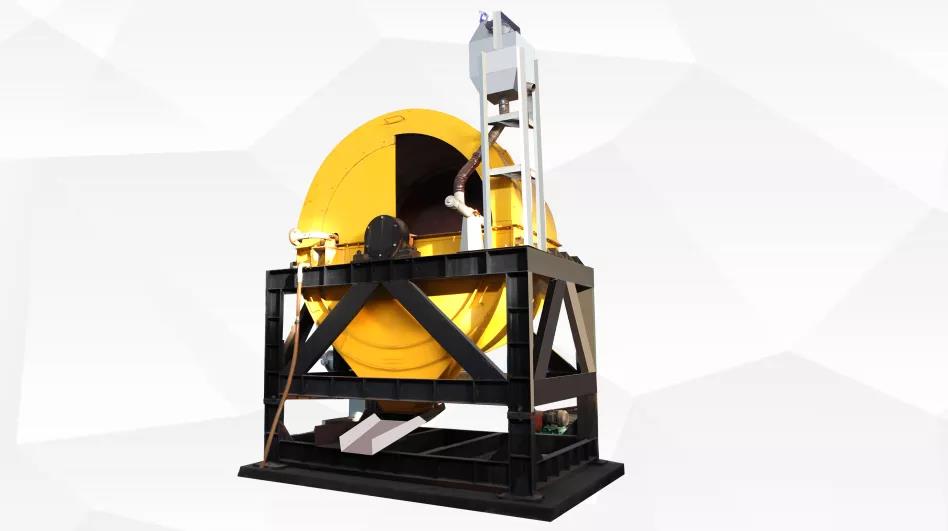

South Africa chromite application site

Heavy media sorting

The specific gravity of chromite is 4.1~4.7g/cm3, and the specific gravity of associated gangue and iron silicate minerals is generally 2.7~3.2g/cm3. Taking advantage of the difference in density between minerals, spiral chute, jigging, shaking table, spiral beneficiation can be used Machines, centrifuges and other heavy sorting equipment for sorting. This method is suitable for chromite with coarser crystal grain size, and the fine particles are easily lost in the tailings.

Flotation

Chromite can use fatty acid or amine collectors to select qualified concentrates through roughing and sweeping processes under suitable pH conditions. It is suitable for fine-grained and fine-grained chromites.

Chemical beneficiation

For some chrome ores that are difficult to be processed by mechanical beneficiation methods, the beneficiation—chemical combined process or a single chemical method is adopted. Chemical beneficiation methods include: selective leaching, redox, fuse separation, sulfuric acid and chromic acid leaching, reduction and sulfuric acid leaching, etc.

Beneficiation example

The grade of Cr2O3 contained in a certain chromite tailing in South Africa is 24.80%. It is an on-site chute re-selection tailings. The sample size is -40 mesh and the particle size is relatively uniform. The chromite is present in fine particles and contiguous bodies and inclusions. The main gangue minerals It is olivine and pyroxene, with a small amount of fine mud. According to the nature of the ore samples, the beneficiation process is established as a flat or vertical ring one-step roughing.

The fine-grained chromite contained in the tailings of the on-site chute gravity separation adopts a flat plate or vertical ring strong magnetic separation process, which can select qualified concentrate products. The chromium-containing minerals in the magnetic tail are fine-grained inclusions or other non- Valuable chromium-containing minerals have achieved good beneficiation indicators.

Post time: Oct-12-2021