Working Principle

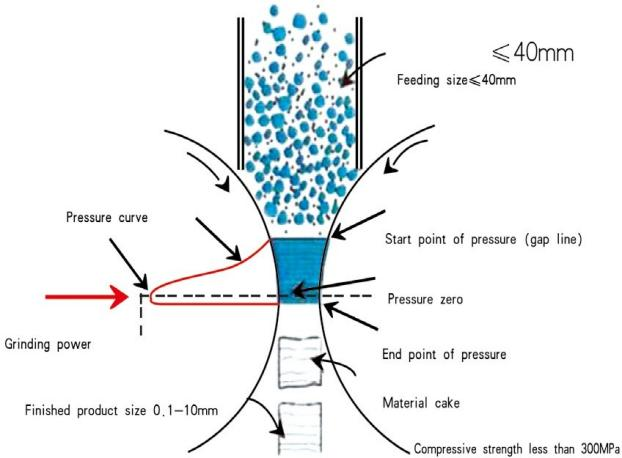

cake, in addition to a certain proportion of the qualified products, the internal structure of the particles of non- qualified products is filled with a large number of micro cracks due to high pressure extrusion, so that the material’s grind ability is greatly improved. For the materials after extrusion, after breaking up, classifying and screening, the fine materials of less than 0.8mm can reach about 30%, and the materials of less than 5 mm can reach more than 80%. Therefore, in the further grinding process, the grinding energy consumption can be reduced to a large extent, so that the production capacity of the grinding equipment can be fully exerted, generally the ball mill system capacity can be increased by 20%~50%, and the total energy consumption can be reduced by 30%~50% or more.

Application Fields

The HPGR has been widely used home and abroad in the grinding in the cement industry, granulation in the chemical industry, and fine grinding of pellet to increase the specific surface area. It is used for the crushing of metal ore to achieve dif- ferent purposes such as simplifying the crushing process, more crushing and less grinding, improving system productivity, improving grinding effect or separation indicators.

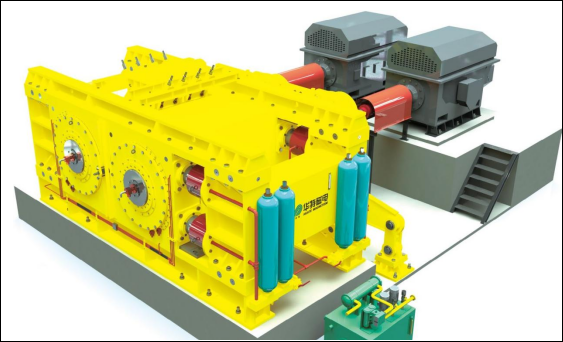

HPGM series high pressure grinding roll is a new type of ener- gy-saving grinding equipment designed by the principle of high-pressure material layer pulverization. It consists of two squeezing rolls that rotate synchronously at a low speed. One is a stationary roll and the other is a movable roll, which are both driven by a high-power motor. The materials are evenly fed from above the two rolls, and are continuous- ly carried into the roll gap by the squeezing roll. After being subjected to a high pressure of 50-300 MPa, the dense material cake is dis- charged from the machine. In the discharged material

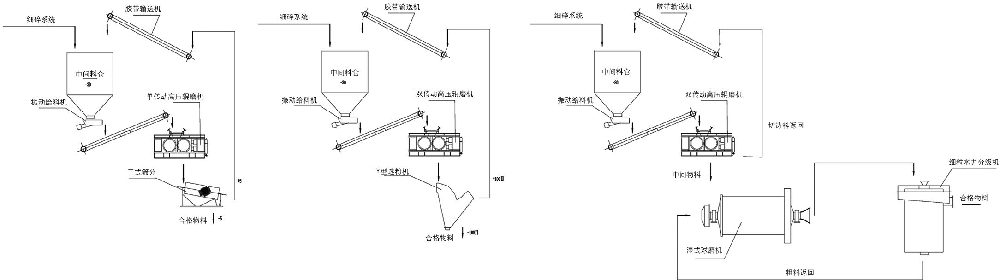

Practical Application Scope

1.Medium, fine and ultrafine grinding of bulk materials.

2.In the mineral processing industry, can be placed before the ball mill, as a pre-grinding equipment, or make up a combined grinding system with a ball mill.

3.In the oxidized pellet industry, can replace the commonly used damp mill.

4.In building materials, refractory materials and other industries, have been successfully applied in cement clinker, limestone, bauxite and other grinding.

Product Advantages

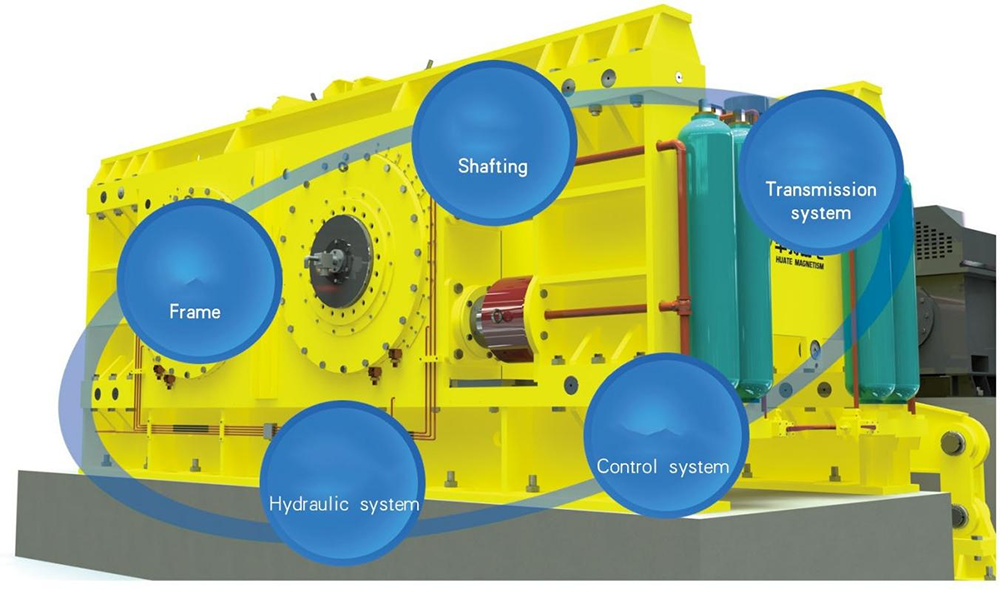

1.Constant pressure design ensures smooth pressure between rolls and ensures crushing effect.

2.Automatic deviation correction, can quickly adjust the roll gap to ensure the smoothness of the equipment.

3.The edge separation system reduces the effect of edge effects on the crushing effect.

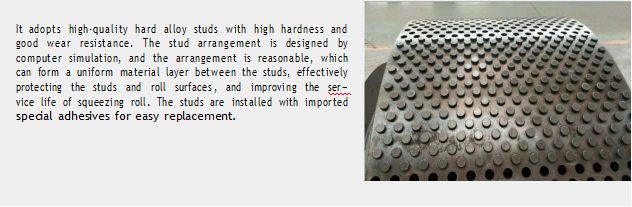

4.With cemented carbide studs, long service life, easy maintenance, and replaceable.

5.The valve bank adopts imported components, and the hydraulic system has reasonable design and good reliability.

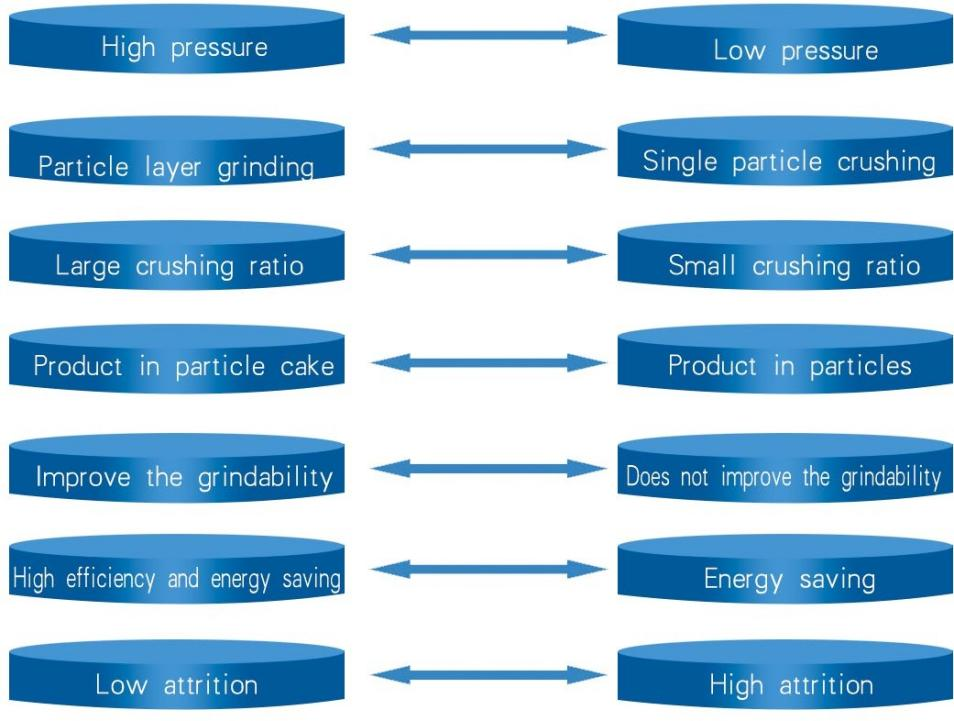

The difference between HPGR and roller crusher

Structure of HPGR

Product Parameters

| Model | Roll diameter mm | Roll width mm | Throughput capacity | Machine weight t | ||

| Feed size | Installed power | |||||

| HPGM0630 | 600 | 300 | 25-40 | 10月30日 | 6 | 74 |

| HPGM0850 | 800 | 500 | 50-110 | 20-35 | 25 | 150-220 |

| HPGM1050 | 1000 | 500 | 90-200 | 20-35 | 52 | 260-400 |

| HPGM1250 | 1200 | 500 | 170-300 | 20-35 | 75 | 500-640 |

| HPGM1260 | 1200 | 600 | 200-400 | 20-35 | 78 | 600-800 |

| HPGM1450 | 1400 | 500 | 200-400 | 30-40 | 168 | 600-800 |

| HPGM1480 | 1400 | 800 | 270-630 | 30-40 | 172 | 800-1260 |

| HPGM16100 | 1600 | 1000 | 470-1000 | 30-50 | 220 | 1400-2000 |

| HPGM16120 | 1600 | 1200 | 570-1120 | 30-50 | 230 | 1600-2240 |

| HPGM16140 | 1600 | 1400 | 700-1250 | 30-50 | 240 | 2000-2500 |

| HPGM18100 | 1800 | 1000 | 540-1120 | 30-60 | 225 | 1600-2240 |

| HPGM18160 | 1800 | 1600 | 840-1600 | 30-60 | 320 | 2500-3200 |

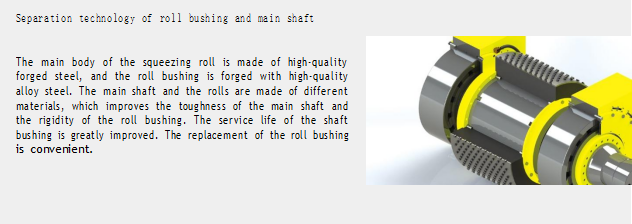

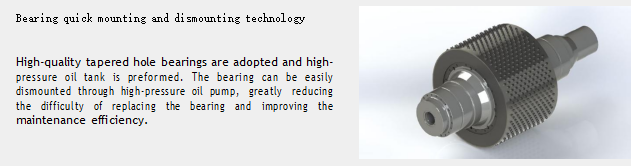

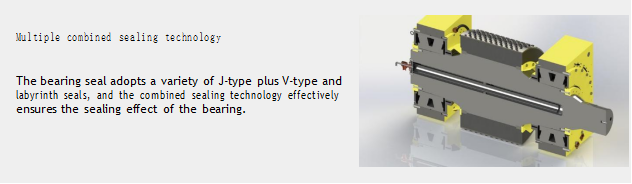

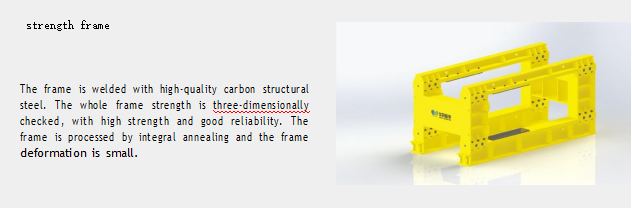

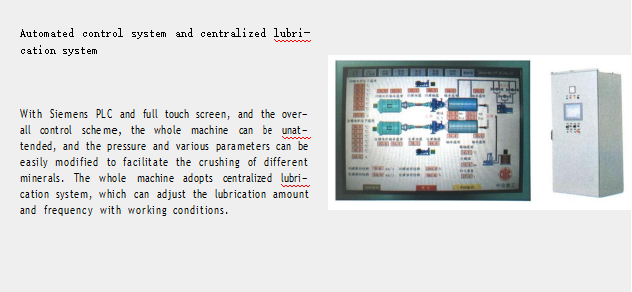

Structural features of HPGR

Project Cases of HPGR

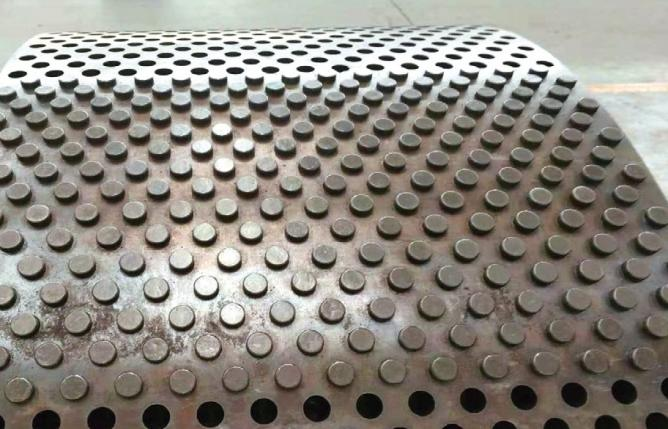

High Quality Wear-Resistant Roll Surface with Studs

After the materials are extruded, a dense material layer is formed on the roll surface to protect the roll surface.

Raw Material

Material Cake

Post time: Jul-02-2024