When it comes to providing top-tier Engineering & Consulting services, Huate Magnet stands out in the field of mineral processing. Our team of experienced technicians is dedicated to thoroughly analyzing your minerals and offering a detailed quotation for the complete construction of a concentrator. This includes an economic benefit analysis tailored to the concentrator’s size, ensuring an integrated and efficient process. With a focus on delivering precise and comprehensive information, our mine consulting services help clients gain a thorough understanding of their ore processing plant’s value, minerals, beneficiation processes, necessary equipment, and construction timeline.

Step-by-Step Mineral Analysis and Consulting

Clients begin by supplying approximately 50kg of representative samples. Our technicians then develop experimental procedures based on a program established through customer communications. These procedures guide exploratory testing and chemical analysis, leveraging extensive experience to assess mineral composition, chemical properties, disaggregation granularity, and beneficiation indices. The results culminate in a comprehensive “Mineral Dressing Test Report,” a crucial foundation for subsequent mine design and practical production guidance.

State-of-the-Art Production and Equipment

Huate Magnet’s production center boasts an annual capacity of 8000 units, supported by over 500 highly skilled employees. Our facility is equipped with advanced processing and manufacturing machinery, allowing us to independently produce core devices such as crushers, grinders, and magnetic separators. By sourcing auxiliary equipment from leading domestic manufacturers, we ensure high cost-efficiency and top quality.

Robust Procurement and Supplier Management

Our mature procurement and supplier management system has fostered long-term cooperative relationships with leading industry suppliers. We procure a wide range of equipment and materials necessary for constructing and operating a beneficiation plant, including excavators, loaders, bulldozers, dressing equipment, water pumps, fans, cranes, and laboratory equipment. This ensures that every aspect of your plant construction and operation is covered.

Meticulous Installation and Commissioning

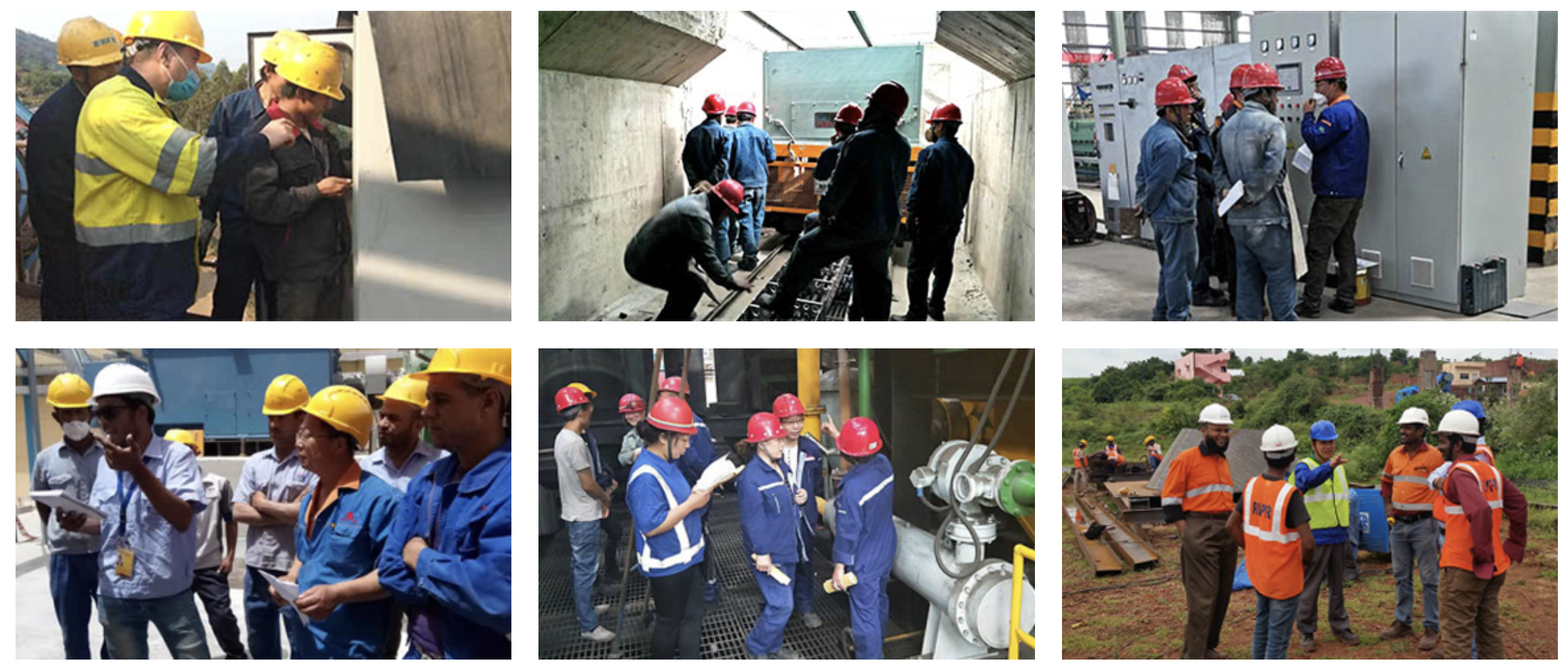

The installation and commissioning of equipment are critical tasks that impact whether a plant meets production standards. Proper installation of standard and non-standard equipment affects overall performance and stability. At Huate Magnet, we ensure meticulous and rigorous installation processes, directly influencing the success and stability of your beneficiation plant.

Integrated Worker Training

Simultaneously training workers during installation and commissioning can reduce construction period costs for customers. Our training serves two primary purposes:

1. Enabling your beneficiation plant to commence production as soon as possible, thereby achieving benefits quickly.

2. Training your technician teams to ensure the smooth and efficient operation of the plant.

Comprehensive EPC Services

Huate Magnet’s EPC services are designed to help your beneficiation plant reach its designed production capacity, achieve expected product granularity, meet quality requirements, and maintain stable operation. Our services include achieving the design index of recovery rate, fulfilling all consumption indexes, controlling production costs, and ensuring the stable operation of process equipment.

Conclusion

Huate Magnet is your trusted partner in providing comprehensive ore processing solutions, from consulting to installation and commissioning. With our expertise and dedication, we help clients maximize the value of their minerals and ensure the efficient operation of their beneficiation plants. Choose Huate Magnet for reliable, high-quality, and cost-effective mineral processing solutions.

Post time: Jul-10-2024