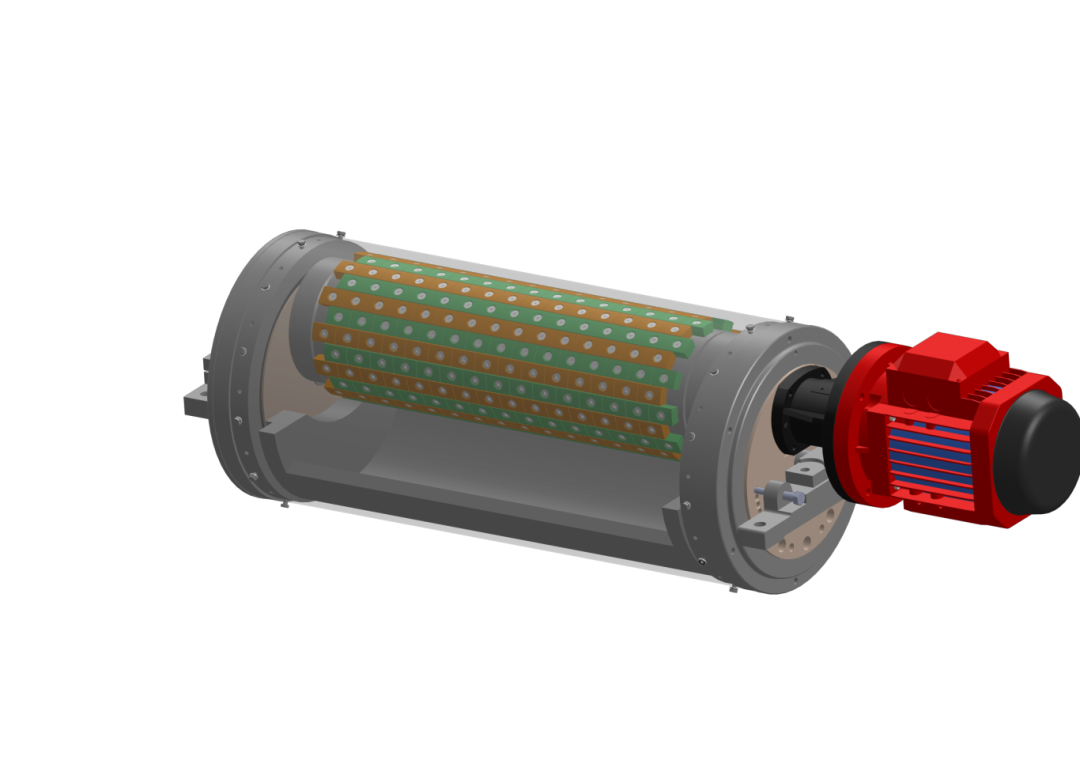

Eddy Current Separator consists mainly of a permanent magnetic drum and a material conveying system (including conveyor belts, drive drums, and reduction motors). It is primarily used for sorting and recovering various non-ferrous metals such as copper and aluminum from industrial solid waste like electronic waste, old plastic windows and doors, and scrap cars. This separator significantly enhances production efficiency, reduces labor intensity, and achieves sorting efficiency of over 98%.

The eddy current separator consists of the main unit, vibratory feeder, and control power source.

Eddy current separation is a sorting technology based on differing material conductivities. It exploits two key physical phenomena: a changing magnetic field induces an alternating electric field (electromagnetic induction), and current-carrying conductors generate a magnetic field (Biot-Savart law).

During operation, the separator generates a high-frequency alternating magnetic field on the surface of the sorting roller. When conductive non-ferrous metals pass through this field, they induce eddy currents. These currents create a magnetic field opposing the original field, causing the metals (such as copper and aluminum) to leap forward due to magnetic repulsion, effectively separating them from non-metallic materials.

Applications include:

- Scrap steel crushing plants: Separating non-ferrous metals from steel scraps.

- Auto dismantling and crushing plants: Sorting non-ferrous metals from crushed materials.

- Electronic waste recycling facilities: Recovering metals from electronic circuit fragments.

- Glass recycling industry: Removing aluminum caps and aluminum or copper alloys from crushed glass materials.

- Household waste pre-sorting: Separating aluminum cans, caps, and copper and aluminum alloys from household garbage.

- Household waste incineration residue recycling: Separating non-ferrous metal particles from incineration residues.

- Paper recycling industry: Sorting non-ferrous metals from paper residues.

- Door and window crushing and aluminum template crushing plants: Separating aluminum and other metals from materials.

- Other occasions: Separating other non-ferrous metal scraps from non-metallic substances.

The eddy current separator developed by huate adopts a unique arrangement of same-pole double-row and staggered configuration, maximizing magnetic field intensity and eddy current strength. This design significantly enhances metal separation efficiency and recycling rates.

Key technical features:

- Simple operation for automatic metal/non-metal separation.

- Easy installation, compatible with new or existing production lines.

- High-intensity magnetic field up to 3000-3500 Gauss, doubling recovery rates compared to standard separators.

- Flexible adjustment for excellent sorting performance.

- Low energy consumption and environmentally friendly.

- Capable of sorting materials of different sizes based on roller rotation direction.

Currently, huate's eddy current separators are widely used domestically and exported to over a dozen countries and regions, earning acclaim from numerous customers worldwide.

Huate Recycled Aluminum Production Line

Post time: Jun-20-2024