Huate Mineral Processing Engineering Design Institute has provided a complete set of EPC general contracting one-stop factory construction services for various mining enterprises, from engineering consultation, mineral processing test, dressing plant design, manufacturing procurement, installation and commissioning, operation and management to the greatest extent. According to the needs of customers, a variety of high-end mineral processing equipment with high quality, high efficiency, environmental protection and other characteristics has been provided for many enterprises, and they have been successfully delivered and put into use, with excellent user response and high satisfaction. With more advanced technology, more efficient equipment, and better service to achieve customers and achieve a win-win situation.

E:Design and R&D

P:Complete equipment manufacturing and procurement

C:Commissioning and Delivery

M+O:Mine Management and Operations

Iron tailings project of a mining group in Australia

An iron ore project in the Philippines

Engineering Consulting:Through the initial communication, understand the project overview, provide ideas and suggestions, and formulate the next work flow.

Mineral Processing Test:Carry out the whole process beneficiation test of the ore, determine the most reasonable process flow, and provide experimental data

Plant Design:Preliminary design and construction drawing design for the processing plant

Effectively overcome the contradiction of mutual restriction and disconnection between design, procurement and construction, which is conducive to the reasonable connection of various stages of design, procurement and construction, effectively realizes the progress, cost and quality control of construction projects, and ensures better investment benefits.

Manufacturing and Sourcing:Strong independent production and manufacturing capabilities, perfect quality management system, procurement and supplier management system, to ensure that production and procurement operate in strict accordance with the quality manual.

Packing&Delivering:The company has full-time personnel responsible for the delivery of packaged goods, and a number of professional logistics companies have long-term cooperation to ensure that the goods arrive at the designated site in good condition and in time.

The scope of work and responsibilities are clearly demarcated, and responsibilities and risks during construction can be largely transferred to the contractor, reducing disputes and claims. The owner can be freed from specific affairs and only focus on the major factors that affect the project to ensure the direction of project management.

Installation and Commissioning:Send experienced installation engineers to work on site, carefully and rigorously install, orderly debug, train operators patiently, and ensure that the production line meets the standard production.

Plant Operation &Management:Responsible for field selection, production and operation, normal operation of production lines and equipment repair and maintenance.

The total contract price and construction period of the EPC project are fixed, and the investment and construction period are relatively clear, which is conducive to cost and progress control.

The design, procurement, and construction phases overlap, which is beneficial to shorten the construction period and reduce costs. According to statistics, the EPC general contracting mode shortens the construction period by 20%-30% compared with the traditional “design-bid-construction” method.

EPC general contracting sets a new benchmark for industry services

A manganese iron ore project in South Africa

A sea sand magnetite processing plant project in Indonesia

An iron ore production line project in India

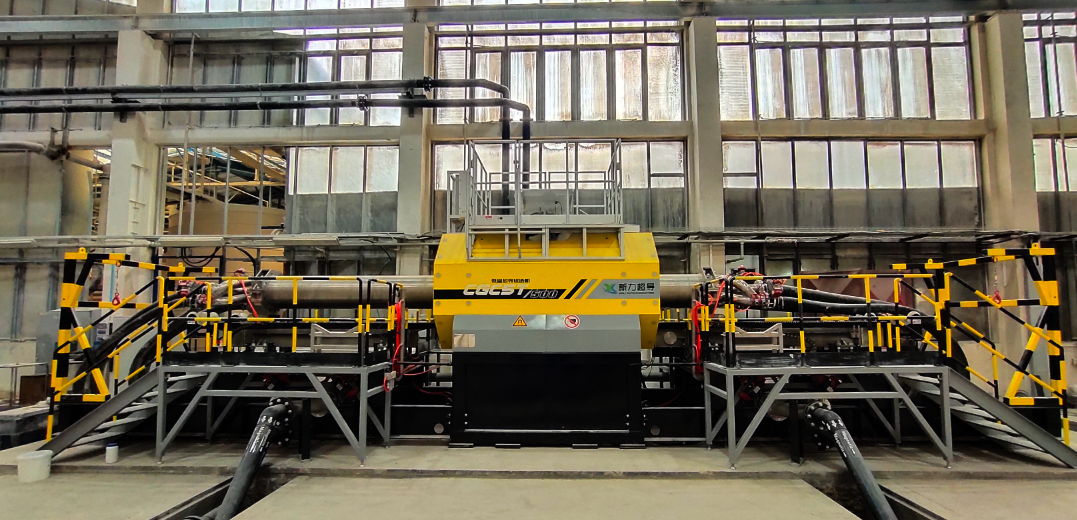

Wet magnetic separation project of Ansteel Group

A hematite wet pre-selection project in Anshan City

A rare earth magnetic separation project in Inner Mongolia

Operation site of Czech superconducting magnetic separator

Operation site of the Austrian quartz project

A large-scale mineral processing plant project in Lianyungang

An ultra-fine-grained magnetite project in Liaoning

Operation site of India kaolin project

A kaolin purification project in Jiangxi

Anhui Quartz Sand Project

Anhui Quartz Sand Project

Professional packaging, transportation, efficient logistics and distribution

Full monitoring of transportation, reliability and timeliness

Professional installation to meet diverse needs

Since its establishment, Huat Magneto has always regarded high-quality customer service and efficient logistics distribution as an important part of enhancing corporate value and reforming and innovating.

Customer-oriented, continue to promote the reform of the service system, continue to provide customers with more convenient, personalized and customized services, lead and promote the transformation and upgrading of industry services, and establish a new benchmark for industry services.

Huate Magnetic has always adhered to the enterprise spirit of “cooperative innovation, pursuit of excellence” and the customer service concept of “customer always comes first”, deepened the awareness of service innovation, increased service innovation, based on core technology, and deeply cultivated innovative service models. Boost the high-quality and leapfrog development of the manufacturing industry.

Post time: Apr-25-2022