Since its establishment 30 years ago, Huate Magnet has adhered to the concept of scientific and technological innovation and development, and is committed to the development and industrialization of energy-saving and environmentally friendly high-tech magnetoelectric technology equipment, intelligent sensor sorting machines, low-temperature superconducting nuclear magnetic resonance and other products. The scope of services covers more than ten fields such as mining, coal, electric power, metallurgy, non-ferrous metals, environmental protection, and medical care, and provides optimized solutions for more than 20,000 customers around the world. The company adheres to the service concept of “customers are always the first”, continues to promote the reform of the service system, strives to create more convenient, personalized and customized services for customers, leads and promotes the transformation and upgrading of industry services, and becomes a globally competitive Magnetic application system service provider!

Huate Magnetoelectric Engineering Case Show

01

A superfine iron tailings reprocessing project in Western Australia, Australia

The annual design capacity of the project is 55 million tons. Our company provides a complete set of magnetic separation equipment, 20 large vertical ring high gradient magnetic separators and 20 large permanent magnet cylinder magnetic separators, and realizes good recovery of fine hematite.

02

A manganese iron ore project in South Africa

This project is a 1 million tons/year manganese ore dressing plant project constructed by our company in South Africa and AMG Group in cooperation with EPC general contracting.

03

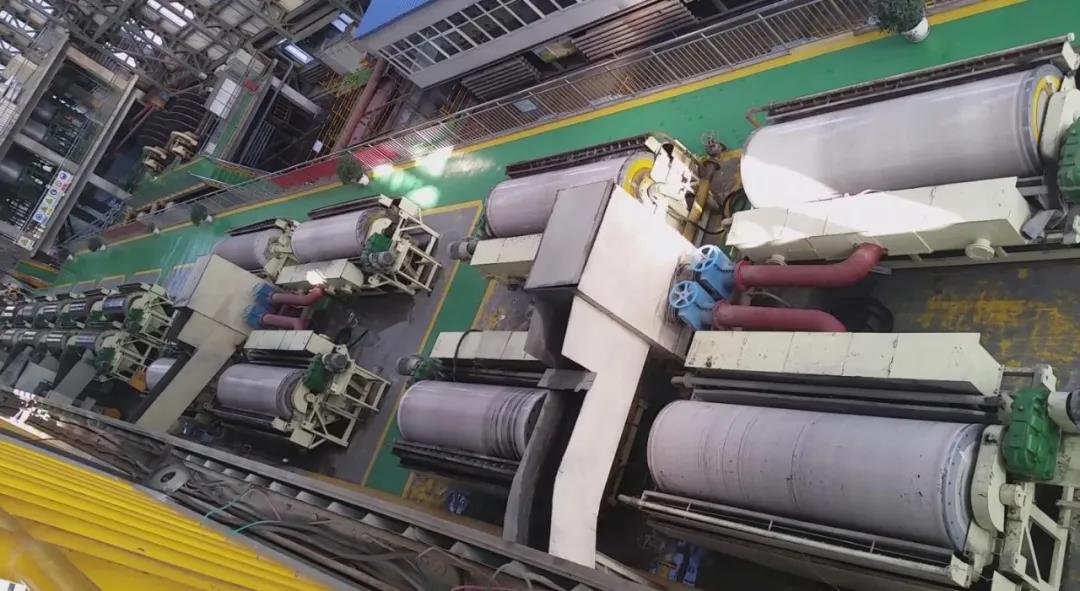

A large-scale concentrator project in Lianyungang City, Jiangsu Province

The project is a modern concentrator that can process magnetite and hematite, with a scale of 6 million tons per year, a short process and a large-scale product. The purchase of four 3.5-meter large vertical ring high-gradient magnetic separators, 6 Products such as a large-scale magnetic separator for refinement and slag reduction, 18 permanent-magnet drum-type magnetic separators and other products have good application effects.

04

A superfine magnetite project in Benxi City, Liaoning Province

The project processes 13 million tons of iron ore annually. The mine belongs to ultra-fine low-grade magnetite. It uses 22 new JCTN-1245 magnetic separators for refinement and slag reduction to realize a short-process, large-scale, low-cost modern large-scale mine

05

A sea sand magnetite concentrator project in Indonesia

This plant is a large-scale magnetite beneficiation production line project constructed by our company’s EPC general contract.

06

An iron ore project in the Philippines

This project is a seaside sand iron beneficiation project constructed by our company’s EPC general contract, with an annual processing capacity of 10 million tons. The production line uses 8 CTY-1545 magnetic separators + CTB-1230 in series to select 58% grade vanadium-titanium magnets The ore concentrate powder, the coarse material on the sieve, is ground and re-selected, and the grade reaches more than 60%.

Post time: Jun-17-2021