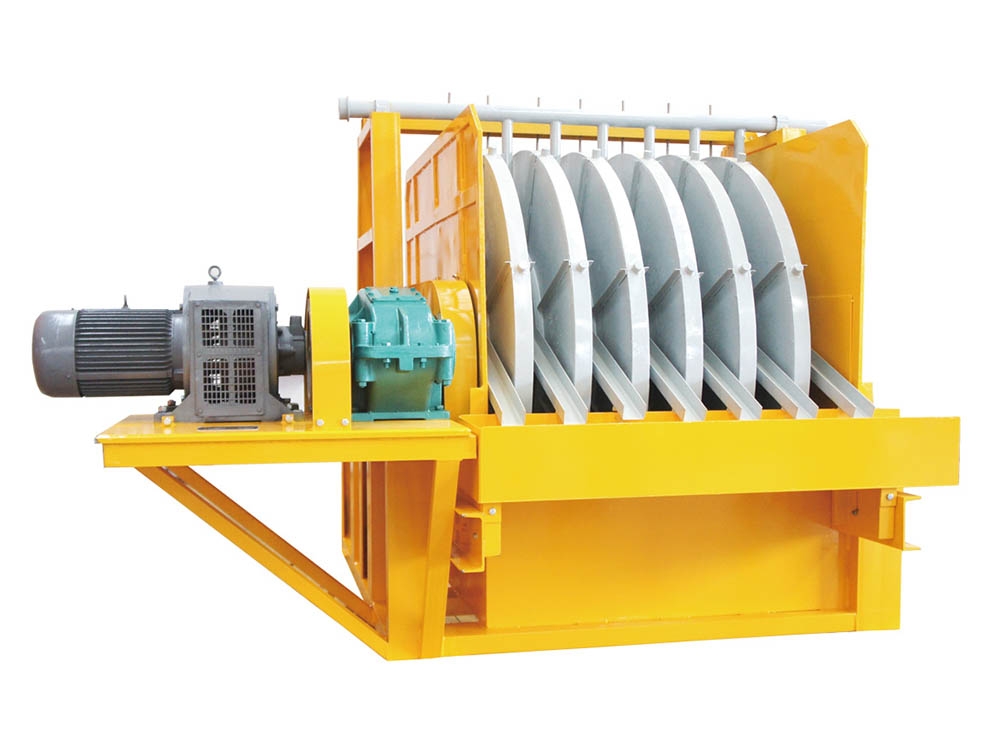

NCTB Series Concentration and De-watering Magnetic Separator

Application

Specially designed for concentrating and increasing the concentration of low concentration pulp in magnetic separation process.

It is mainly used to concentrate coarse-grained minerals under high-frequency sieve, which is beneficial to improve the efficiency and production cost of secondary mill.

Technical Features

High concentration of concentrate discharge:

◆ The magnetic system adopts large wrap angle design to prolong the separation length and discharge time.

◆ Optimal design of tank body, Optimize the ore discharge gap and ore unloading height of tank body, the Concentration of concentrate discharge is over 68%, with high recovery rate.

◆ The magnetic system adopts high gradient design and large wrap angle structure, which effectively controls the high grade recovery rate of magnetic separation tailings and can directly throw tailings while concentrating operations.

Technical Parameters

|

|

Drum size | Drum surfacemagneticIntensity

mT |

processing Capacity | Motor powerkW | Drum rotating speedr/min | Weightkg | ||

| D mm | L mm | t/h | m3/h | |||||

| NCTB-918 | 900 | 1800 |

to determine the magnetic induction intensity according to the mineral grade |

25-40 | 70-120 | 4 | 25 | 2700 |

| NCTB-1018 | 1050 | 1800 | 40-60 | 130-200 | 5.5 | 22 | 3100 | |

| NCTB-1021 | 1050 | 2100 | 50-70 | 150-240 | 5.5 | 22 | 3500 | |

| NCTB-1024 | 1050 | 2400 | 60-80 | 160-280 | 7.5 | 22 | 4000 | |

| NCTB-1030 | 1050 | 3000 | 80-120 | 240-400 | 7.5 | 22 | 5000 | |

| NCTB-1218 | 1200 | 1800 | 60-75 | 160-280 | 11 | 17 | 5000 | |

| NCTB-1224 | 1200 | 2400 | 80-110 | 240-380 | 11 | 17 | 6000 | |

| NCTB-1230 | 1200 | 3000 | 100-140 | 260-400 | 11 | 17 | 6500 | |

| NCTB-1236 | 1200 | 3600 | 120-160 | 300-550 | 15 | 17 | 7200 | |

| NCTB-1240 | 1200 | 4000 | 130-170 | 330-600 | 18.5 | 17 | 8000 | |

| NCTB-1245 | 1200 | 4500 | 150-200 | 380-660 | 18.5 | 17 | 9200 | |

| NCTB-1530 | 1500 | 3000 | 100-180 | 290-480 | 15 | 15 | 10500 | |

| NCTB-1540 | 1500 | 4000 | 150-200 | 320-540 | 22 | 15 | 12500 | |

| NCTB-1545 | 1500 | 4500 | 180-240 | 400-650 | 22 | 15 | 14700 | |

| NCTB-1550 | 1500 | 5000 | 210-280 | 500-750 | 30 | 15 | 16500 | |

Outline and Installation size

|

Model/Size |

A | B | B1 | B2 | B3 | B4 | C | D | E | F | G | H | HO | H1 | K | L | L1 | L2 | L3 | L4 | M |

| NCTB1018 | 3300 | 2000 | 1300 | 278 | 480 | 529 | 2250 | 650 | 800 | 2 | 327 | 1600 | 1190 | 1447 | 1125 | 930 | 1200 | 455 | 180 | 200 | 0 |

| NCTB1021 | 3500 | 2000 | 1300 | 278 | 480 | 529 | 2550 | 650 | 1000 | 2 | 327 | 1600 | 1190 | 1447 | 1275 | 930 | 1200 | 455 | 180 | 200 | 0 |

| NCTB1024 | 3900 | 2000 | 1300 | 278 | 480 | 529 | 2850 | 650 | 1250 | 2 | 327 | 1600 | 1190 | 1447 | 1425 | 930 | 1200 | 455 | 180 | 200 | 350 |

| NCTB1030 | 4500 | 2000 | 1300 | 278 | 480 | 529 | 3450 | 650 | 1550 | 2 | 327 | 1600 | 1190 | 1447 | 1725 | 930 | 1200 | 455 | 180 | 200 | 1675 |

| NCTB1218 | 3400 | 2380 | 1655 | 300 | 499 | 695 | 2600 | 690 | 1050 | 2 | 408 | 1945 | 1445 | 1733 | 1260 | 1165 | 1359 | 565 | 240 | 298 | / |

| NCTB1224 | 4000 | 2380 | 1655 | 300 | 499 | 695 | 2900 | 690 | 1200 | 2 | 408 | 1945 | 1445 | 1733 | 1410 | 1165 | 1359 | 565 | 240 | 298 | / |

| NCTB1230 | 4600 | 2380 | 1655 | 300 | 499 | 695 | 3500 | 690 | 900 | 3 | 408 | 1945 | 1445 | 1733 | 1710 | 1165 | 1359 | 565 | 240 | 298 | / |

| NCTB1236 | 5334 | 2380 | 1655 | 300 | 499 | 695 | 4100 | 690 | 900 | 4 | 408 | 1945 | 1445 | 1733 | 2010 | 1165 | 1359 | 565 | 240 | 298 | / |

| NCTB1240 | 5727 | 2380 | 1655 | 300 | 499 | 695 | 4500 | 790 | 820 | 5 | 408 | 1945 | 1445 | 1733 | 2210 | 1165 | 1359 | 565 | 240 | 298 | / |

| NCTB1245 | 6222 | 2380 | 1655 | 300 | 499 | 695 | 5000 | 790 | 920 | 5 | 408 | 1945 | 1445 | 1733 | 2460 | 1165 | 1359 | 565 | 240 | 298 | / |

| NCTB1530 | 4510 | 2710 | 1962 | 265 | 646 | 955 | 3720 | 820 | 1000 | 3 | 486 | 2270 | 1700 | 2037 | 1810 | 1325 | 1640 | 825 | 260 | 317 | 1500 |

| NCTB1540 | 6100 | 2710 | 1962 | 265 | 646 | 955 | 4720 | 820 | 1000 | 4 | 486 | 2270 | 1700 | 2037 | 2310 | 1325 | 1640 | 825 | 260 | 317 | 2700 |

| NCTB1545 | 6600 | 2710 | 1962 | 265 | 646 | 955 | 5220 | 820 | 920 | 5 | 486 | 2270 | 1700 | 2037 | 2560 | 1325 | 1640 | 825 | 260 | 317 | 3120 |

| NCTB1550 | 7300 | 2710 | 1962 | 265 | 646 | 955 | 5720 | 1050 | 950 | 5 | 550 | 2270 | 1763 | 2037 | 2810 | 1325 | 1640 | 825 | 260 | 317 | 3440 |