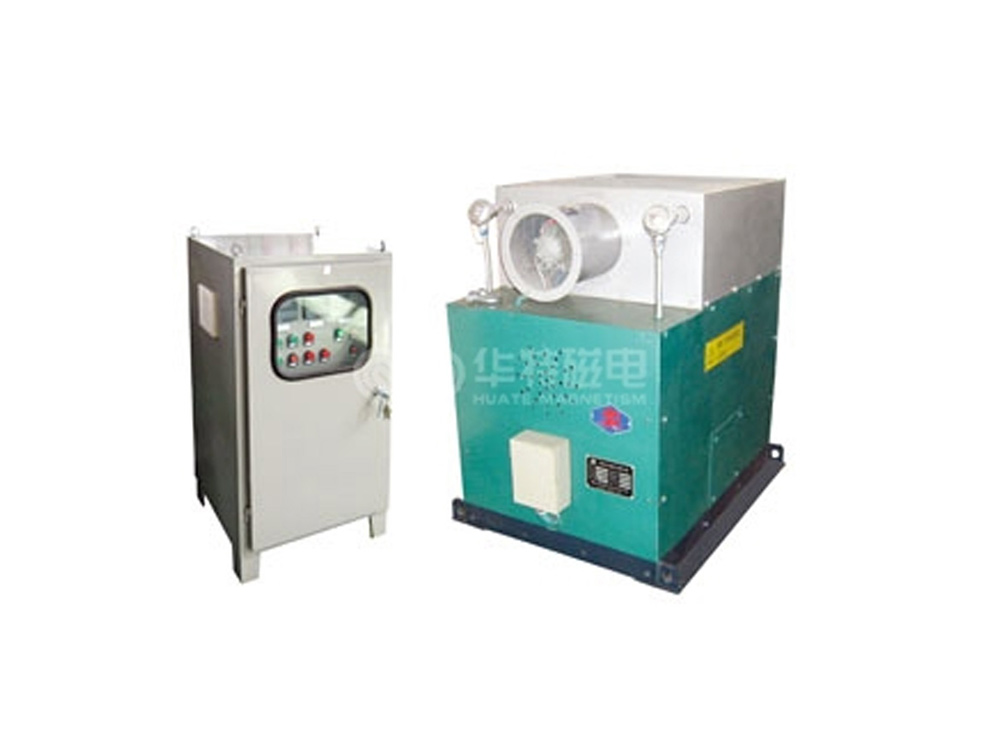

Mid – field strong semi – magnetic self – discharging tailings recovery machine

Application

This product is suitable for the separation of magnetic minerals. It can enrich the magnetic minerals in the tailing slurry, suspend the magnetic ore powder for regeneration, or remove the magnetic impurities from other suspensions.

Features

◆The magnetic disk is an annular semi-magnetic structure, and the aggregate disk (shell) is fully sealed. The lower part of the aggregate disk is immersed in the pulp groove, and the magnetic particles in the pulp are continuously absorbed by continuous rotation.

◆The magnetic disk is provided with medium magnetic field area, weak magnetic field area and non-magnetic area. The magnetic disk absorbs materials in the magnetic area and discharges materials in the non-magnetic area.

◆Magnetic areas are arranged alternately by several groups of opposite polarity magnetic pole pairs. Magnetic materials are continuously rolled in the process of rotation of the aggregate disk to wash off mud, so that the recovered magnetic materials have higher purity and better recovery effect compared with the ordinary tailing recovery machine.

◆The radial distribution of the material guide plate at both ends of the aggregate disk reduces the back movement and leakage of the magnetic material.The agitating block agitates the pulp to prevent material deposition.

◆The transmission system has reasonable structure, reliable seal and adjustable speed.

Major Technical Parameters:

|

Model |

Adsorbed surface magnetic intensity (mT) |

Pulp capacity (m3/h) |

Reclaiming quantity (t/h) |

Tank width (mm) |

Diameter (mm) |

Total rings (set) |

Motor (kW) |

|

YCBW-8-4 |

≥ 300 |

50-100 |

0.5-1 |

750 |

|

Φ800 |

2.2 |

|

YCBW-8-6 |

100-200 |

1-2 |

1030 |

|

3.0 |

||

|

YCBW-10-4 |

200-300 |

2-4 |

750 |

|

Φ1000 |

4.0 |

|

|

YCBW-10-6 |

400-500 |

3-5 |

1030 |

|

|||

|

YCBW-12-6 |

500-600 |

5-7 |

1230 |

|

Φ1200 |

5.5 |

|

|

YCBW-12-8 |

600-700 |

5-8 |

1600 |

|

|||

|

YCBW-12-10 |

700-850 |

7-10 |

1950 |

|

|||

|

YCBW-15-6 |

600-700 |

5-8 |

1230 |

|

Φ1500 |

7.5 |

|

|

YCBW-15-8 |

700-850 |

7-10 |

1600 |

|

|||

|

YCBW-15-10 |

850-1000 |

9-11 |

1950 |

|

|||

|

YCBW-15-12 |

1000-1200 |

11-16 |

2320 |

|

|||

|

YCBW-15-14 |

1200-1400 |

13-18 |

2690 |

|