LHGC Intelligent Oil-Water Cooling Vertical Ring High Gradient Magnetic Separator

Company Profile

Shandong Huate Magnet Technology Co., Ltd, the World-leading Magnetic Application System Service Provider, was founded in 1993,

and is headquartered in Weifang, China with a total area of 270,000 square meters and more than 800 employees. Huate Magnet specializes in manufacturing superconducting magnet, cryogenic superconducting magnetic separation equipment, vertical ring high gradient magnetic separator (WHIMS), slurry electromagnetic separator, magnetic iron separator, magnetic stirrer, ultra-fine grinding and classifying equipment, mining compete set equipment, medical magnetic resonance imaging (MRI) etc. The service scope involves mine, coal, electricity, building material, metallurgy, non-ferrous metal, environmental protection, medical and so on more than 10 fields. With more than 20,000 customers, Huate’s products have been exported to 30 countries such as Germany, Australia, Czech Republic, India, Brazil and South Africa.

Technical Features

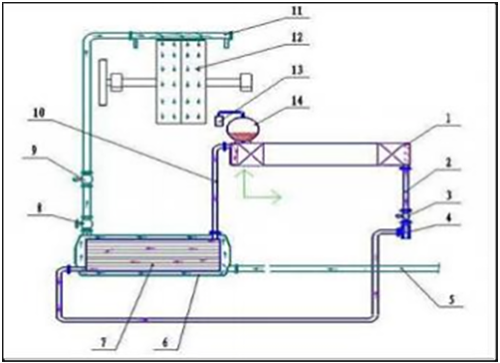

1. Oil-water Heat Exchange Cooling Technology

The coil adopts large-flow external circulation oil-water heat exchange for heat dissipation. The coil temperature rise is less than 25°C, the magnetic field heat attenuation is small, and the mineral processing index is stable. The coil adopts a fully sealed structure, which is rain-proof, dust-proof and corrosion-resistant, which can adapt to various harsh working environments.

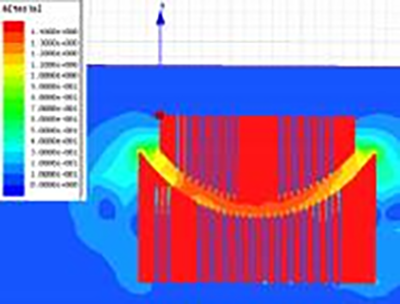

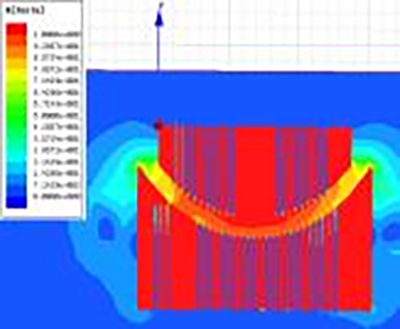

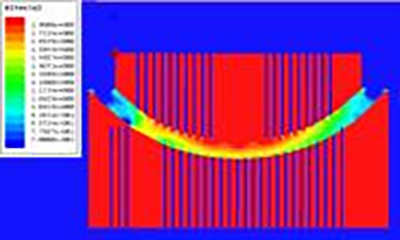

2. Precise Magnetic Circuit Design

Using finite element simulation optimization, the magnetic circuit design is reasonable, the magnetic energy loss is small, and the magnetic field strength can reach 0.6T, 0.8T, 1.0T, 1.3T, 1.5T, 1.8T

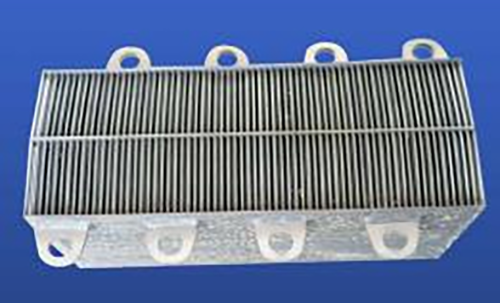

3. Long-life Integrated Magnetic Matrix

The matrix adopts an one-piece through-type structure, and the medium rods do not fall off; the fixing lug plate adopts a conical structure design, and the connection strength is high; it is welded with special robot equipment, with reliable quality and strong interchangeability.

4. Flushing Water Mineral Discharge System

The pressure of the flushing water is detected in real time, so that the flushing water maintains sufficient pressure and flow, and the minerals in the matrix are discharged thoroughly.

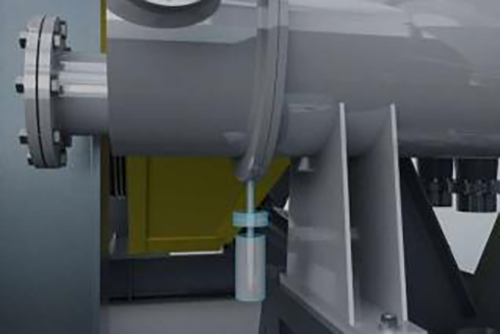

5. Liquid Level Automatic Control System

The liquid level fluctuation state of the separation chamber is detected in realtime by the ultrasonic sensor, and it is linked with the electric actuator, so that the liquid level of the separation chamber always maintains at the best separation state; manual operation is reduced, and the difficulty of manual inspection is lowered; excessive amount of instantaneous slurry is prevented to avoid overflow.

6. Temperature Alarm Protection System

Coil temperature sensors are provided to detect the working temperature of the coil in real time and feed back the information to the control center. When the coil temperature exceeds the set value, the system will automatically alarm, and the equipment will stop working when the upper limit is reached to ensure the safe operation of the equipment.

7. Leakage Alarm Device

The cooler adopts a double-layer tube-plate structure, and there is a leakage detection device between the layers. When leakage occurs, the equipment will automatically alarm and stop, so as to avoid the damage to the coil caused by the ingoing water in the cooling oil.

8. Automatic Lubrication System

The ring drive gear adopts an idle gear automatic lubricating device to ensure that the equipment can realize automatic quantitative lubrication without stopping the operation and improve the operation rate..

9. Remote Intelligent Service Platform Based on Internet of Things Technology

The Internet of Things and cloud platform technologies are applied to collect and analyze equipment operation data in real time to realize remote operation and maintenance, fault diagnosis and full life cycle management of equipment.

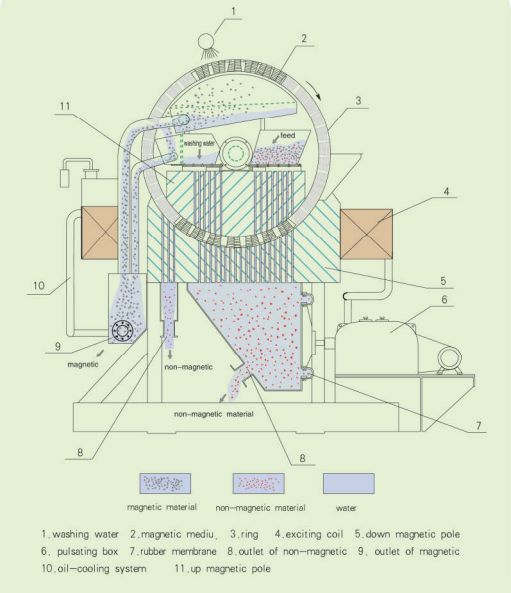

Operating Principle

The slurry is introduced to the feeding hopper through the feeding pipe, and enters the magnetic matrix on the rotating ring along the slots in the upper magnetic pole. The magnetic matrix is magnetized, and a high gradient magnetic field is generated on its surface. The magnetic particles are attracted on the surface of the magnetic matrix, and are brought to the

non-magnetic area at the top with the rotation of the ring, and then are flushed into the collection hopper by pressure water flushing. The non-magnetic particles flow into the non-magnetic material collection hopper along the slots in the lower magnetic pole to be discharged.

Applications

It is suitable for wet concentration of various weakly magnetic metallic ores such as hematite, limonite, specularite, manganese ore, ilmenite, chrome ore, rare earth ore, etc., as well as for iron removal and purification of non-metallic minerals such as quartz, feldspar and kaolin.

Upgrades

■Oil-water cooling technology of coil

■Flushing water mineral discharge system

■Temperature alarm protection system

■Automatic lubrication system

■Long-life integrated magnetic matrix

■Liquid level automatic control system

■Cooler leakage alarm system

■Intelligent remote monitoring system

LHGC Advantages Over Traditional Vertical Ring WHIMS

| Traditional vertical ring WHIMS concerns | LHGC Solutions |

| The coil adopts hollow wire and water cooling method. The inner wall of the wire is easy to form lime scale, and it must be acid cleaned regularly, the failure rate is high, and the coil life is short. | The coil is immersed in oil for cooling, and adopts forced large-flow external circulation, which has fast heat dissipation, low temperature rise and is maintenance-free. The coil shell adopts a fully sealed structure, which is more suitable for more harsh environments. |

| The rod matrix falls off easily | The matrix adopts a one-piece through-type structure, and the medium rods do not fall off; the fixing lug plate adopts a conical structure design, which has high connection strength and is not easy to break. |

| Slurry overflow | |

| Manual lubrication, low safety level | Idle gear automatic lubrication, safe and reliable |

| Manual operation and maintenance,labor-intensive | Intelligent control, unattended operation |

The LHGC oil-water cooling vertical ring high gradient magnetic separator (WHIMS)

(1.3T/1.5T/1.8T)Major technical parameters:( non-metallic minerals)

In principle,the model selection of equipment is subject to the amount of mineral slurry.when separating minerals using

this kind of equipment, the slurry concentration has certain influence on the mineral processing index.To get better mineral processing index,please reduce the slurry concentration properly. If the ratio of the magnetic materials in the mineral feed is slightly high, the processing capacity will be limited to the total catching amount of magnetic minerals by magnetic

matrix, in the case, the feed concentration should be reduced appropriately.

| LHGC 1000F | LHGC 1250F | LHGC 1500F | LHGC 1750F | LHGC 2000F | LHGC 2250F | LHGC 2500F | LHGC 2750F | LHGC 3000F | LHGC 3500F | LHGC 4000F | LHGC 4500 | LHGC 5000F | ||

| Background Filed (T) | 1.3/1.5(1.8) Constant current continuously adjustable | |||||||||||||

|

Rated exciting(kW) |

25 | 36 | 38 | 46 | 56 | 60 | 72 | 82 | 90 | 105 | 118 | 130 | 140 | |

| 35 | 42 | 53 | 58 | 68 | 78 | 85 | 100 | 120 | 130 | 140 | 156 | 172 | ||

| 56 | 68 | 82 | 98 | 115 | 130 | 150 | 165 | 180 | 205 | 230 | 248 | 268 | ||

| Capacity(t/h) | 2 ~3.5 | 5 ~9 | 10 ~15 | 15 ~25 | 25 ~40 | 33 ~60 | 40 ~75 | 50 ~100 | 75 ~125 |

125 ~200 |

175 ~275 |

225 ~350 |

300 ~480 | |

| Pulp capacity(m3/h) | 12.5 ~20 | 20 ~50 | 50 ~100 | 75 ~150 | 100 ~200 | 160 ~300 | 200 ~400 | 250 ~500 | 350 ~650 | 550 ~1000 | 750 ~1400 | 1100 ~1700 | 1200~2400 | |

|

Exciting current(A) |

50 | 80 | 130 | 135 | 150 | 175 | 172 | 200 | 207 | 217 | 262 | 280 | 288 | |

| 80 | 125 | 140 | 150 | 180 | 215 | 216 | 250 | 285 | 268 | 285 | 300 | 340 | ||

| 150 | 160 | 280 | 290 | 310 | 320 | 330 | 340 | 348 | 350 | 362 | 372 | 385 | ||

| Feed density(%) | 10 ~35 | |||||||||||||

| Feed size(mm) | -1.2 | |||||||||||||

| Ring rotation speed

(r/min) |

2 ~4 | |||||||||||||

| Ring outer diameterφ

(mm) |

1000 | 1250 | 1500 | 1750 | 2000 | 2250 | 2500 | 2750 | 3000 | 3500 | 4000 | 4500 | 5000 | |

|

Motor power of Ring(kW) |

1.1 | 1.5 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | 37 | 45 | 55 | |

| Exciting voltage(DCV) | (1.3T ~1.5T)0 ~514( Change with current) /(1.8T)0~695 Change with current) | |||||||||||||

| Water pressure(Mpa) | 0.2 ~0.4 | |||||||||||||

| Water consumption

(m3/h) |

8 ~12 | 12 ~20 | 20 ~30 | 30 ~50 | 50 ~100 | 75 ~125 | 100 ~150 | 125 ~200 | 150 ~250 | 250 ~350 | 350 ~500 | 450 ~600 | 550 ~800 | |

| Weight for largestPart(t) | 2.8/3(4.7) | 3/6(12) | 9/14(20) |

14/19(22) |

20/22(28) |

22/23(30) |

24/25(32) |

25/26(34) |

33/36(38) |

50/52(55) | 70/72(75) | 74/77(80) | 80/82(85) | |

|

Outline dimension (mm) |

L |

2360 | 2500 | 2670 | 2880 | 3810 | 4570 | 3660 | 3915 | 4410 | 4740 | 5470 | 5980 | 6410 |

| 2510 | 2780 | 2700 | 3000 | 3250 | 4620 | 3850 | 4260 | 4570 | 5530 | 5750 | 6160 | 6680 | ||

| 3120 | 3210 | 3760 | 3970 | 4170 | 4750 | 5200 | 5380 | 5510 | 5680 | 5820 | 6270 | 6820 | ||

|

W |

2700 | 2880 | 3320 | 3540 | 4320 | 4590 | 4690 | 4840 | 5540 | 5860 | 6350 | 6630 | 6840 | |

| 2850 | 3420 | 3700 | 3900 | 4080 | 4600 | 5050 | 5130 | 5820 | 5930 | 6750 | 6890 | 7170 | ||

| 2520 | 3580 | 3630 | 4330 | 5040 | 5230 | 5400 | 5620 | 5800 | 6350 | 6900 | 7210 | 7330 | ||

|

H |

2450 | 2860 | 3400 | 3710 | 4250 | 4800 | 5290 | 5760 | 6450 | 7435 | 8570 | 9200 | 9700 | |

| 2630 | 3000 | 3650 | 4060 | 4480 | 4850 | 5500 | 5960 | 6610 | 7200 | 8650 | 9480 | 9650 | ||

| 2490 | 3300 | 3800 | 4300 | 4800 | 5280 | 5760 | 6250 | 6730 | 7950 | 9150 | 9600 | 9800 | ||

The LHGC oil-water cooling vertical ring high gradient magnetic separator (WHIMS)

(1.1T/0.6T)Major technical parameters:(non-metallic minerals)

| LHGC

1000F |

LHGC

1250F |

LHGC

1500F |

LHGC

1750F |

LHGC

2000F |

LHGC

2250F |

LHGC

2500F |

LHGC

2750F |

LHGC

3000F |

LHGC

3500F |

LHGC

4000F |

LHGC

4500F |

LHGC

5000F |

||

| Background Filed

(T) |

1.1/(0.6) Constant current continuously adjustable | |||||||||||||

| Rated exciting(kW) | ≤17/(10) | ≤19/(12) | ≤32/(15.5) | ≤37/(23) | ≤49/(29) | ≤51/(32) | ≤65/(41) | ≤69/(42) | ≤72/(50) | 93/(52) | 102/(58) | 110/(65) | 128/(75) | |

| Capacity(t/h) | 2~3.5 | 5~9 | 10~15 | 15~25 | 25~40 | 33~60 | 40~75 | 50~100 | 75~125 | 125~ 200 | 175~ 275 | 225~ 350 | 300~

480 |

|

| Pulp capacity

(m3/h) |

12.5~20 | 20~50 | 50~100 | 75~150 | 100~200 | 160~300 | 200~400 | 200~500 | 350~650 | 550~1000 | 750~1400 | 1100~1700 | 1200~2500 | |

| Exciting current(A) | 41/(70) | 70/(85) | 110/(110) | 120/(125) | 140/(130) | 146/(120) | 165/(120) | 225/(100) | 185/(150) | 205/(180) | 263/(205) | 270/(220) | 272/(330) | |

| Feed density(%) | 10~35 | |||||||||||||

| Feed size(mm) | -1.2 | |||||||||||||

| Ring rotation speed

(r/min) |

2~4 | |||||||||||||

| Ring outer diameter

φ(mm) |

1000 | 1250 | 1500 | 1750 | 2000 | 2250 | 2500 | 2750 | 3000 | 3500 | 4000 | 4500 | 5000 | |

| Motor power of Ring

(kW) |

1.1 | 1.5 | 3 | 4 | 5.5 | 7.5 | 11

(7.5) |

15 | 18.5

(15) |

30 | 37 | 45 | 55 | |

| Exciting voltage

(DCV) |

0~514(Change with current)) | |||||||||||||

| Water pressure

(Mpa) |

0.2~0.4 | |||||||||||||

| Water consumption

(m3/h) |

8~12 | 12~20 | 20~30 | 30~50 | 50~100 | 75~125 | 100~ 150 | 150~ 200 | 150~ 250 | 250~ 350 | 350~ 500 | 450~ 600 | 550~

800 |

|

| Weight for largest

Part(t) |

3.5/(2) | 4/(3.5) | 9.3/(4) | 15/(9) | 20/(13) | 24/(16) | 24/(17) | 21/(18) | 33/(25) | 50/(47) | 68/(60) | 72/(64) | 80/(72) | |

|

Outline dimension (mm) |

L |

2360 | 2780 | 3000 | 2970 | 3170 | 4400 | 3660 | 3915 | 4410 | 4900 | 5470 | 6670 | 7100 |

| 2260 | 2680 | 2900 | 2870 | 3070 | 4300 | 3650 | 3910 | 4150 | 7400 | 5310 | 6220 | 7000 | ||

|

W |

2700 | 3270 | 3320 | 3540 | 3810 | 4400 | 4690 | 4830 | 5540 | 5500 | 6240 | 7150 | 7650 | |

| 2600 | 3110 | 3220 | 3440 | 3710 | 4300 | 3785 | 3910 | 4630 | 7750 | 5910 | 6740 | 7130 | ||

|

H |

2480 | 2850 | 3330 | 3710 | 4250 | 4600 | 5290 | 5760 | 6450 | 4400 | 8520 | 8930 | 9600 | |

| 2380 | 2750 | 3230 | 3610 | 4150 | 4150 | 5175 | 5650 | 6280 | 7200 | 8340 | 8850 | 9380 | ||

The Site Cases

The World’s Largest 5-meter WHIMS

Roll Off Ceremony

Iron Mine Project in Australia

Iron Mine Project in China

Quartz Sand Project in Austria