JCTN Drum Permanent Magnetic Separator

Application

This product is a wet magnetic separator designed for rinsing and purification of magnetic ore. According to the process requirements, the magnetic ore is washed, selected and purified, deslimed and concentrated. Applicable to: sorting and desliming of graded overflow products after primary grinding; mineral concentration before secondary grinding and filtration; desliming of magnetite before entering fine sieve screening and desliming before reverse flotation; It is the ultimate selection of magnetite.

JCTN Working Principle

After the ore slurry is fed into the tube feeding device 1, it is directly fed into the equipment sorting area through the gap-type cloth. The magnetic minerals in it are firstly magnetized and chained and layered, and then directly adsorbed on the surface of the drum 3 by the high-efficiency magnetic force, and the magnetic concentrate is taken out of the liquid surface by the counter-rotating drum 3, and the magnetic concentrate is transported upwards. The separation of water and ore can be realized in the process of conveying, and the concentration can be increased. At the same time, after the concentrate is separated from the liquid surface, it is affected by the built-in stirring magnetic field on the surface of the drum 3 to realize the mechanical movement of repeated agglomeration, dispersion, and agglomeration of ore particles. , and under the rinsing of multi-stage rinsing water 2, impurities such as silicon, sulfur, phosphorus and poor aggregate in the concentrate can be effectively shaved off, so that the grade of the concentrate can be improved as much as possible. Finally, the double-layer scraper (Discharge device 4 and scraper 5), it is enriched into the concentrate box 6 to become concentrate; and the non-magnetic minerals and lean associated organisms, together with the ore flow, enter the tailings outlet 7 at the bottom of the sorting tank to become tailings or middlings.

JCTN Magnetic Separator Patent Innovation Points

◆ Innovation Point One: Multi-stage rinse water device

The tank body is equipped with multi-channel rinsing devices, which use specially arranged stainless steel nozzles to fully rinse the minerals on the surface of the drum, so that impurities such as silicon, sulfur, phosphorus and poor aggregate in the concentrate can be effectively shaved,to improve the concentrate grade as much as possible.

◆ Innovation Point Two: Top curtain rinse structure

The top of the tank is equipped with a water curtain rinsing structure, which can effectively bring silicon, sulfur, phosphorus and other impurities in the magnetic agglomeration opened under the action of the multi-stage rinsing water device and the magnetic agitation device and poor aggregate to the tailings, and can reduce impurities into the concentrate.

◆ Innovation Point Three: Large wrap angle multi-pole magnetic system structure

The magnetic system structure with 240° ~ 270° large wrap angle and multiple magnetic poles can make the minerals roll on the surface of the drum multiple times, and effectively remove the silicon, sulfur, phosphorus, etc. mixed in the minerals, thereby improving the grade of the concentrate.

◆ Innovation Point Four: Magnetic pulsation magnetic circuit technology

There is a magnetic stirring device inside the drum skin, so that the minerals attached to the surface of the drum can be effectively magnetically stirred, combined with the multi-pole magnetic system to generate a pulsating magnetic field, so that the minerals are repeatedly agglomerated and dispersed, and rinsed with rinsing water, It can effectively remove harmful substances such as silicon, sulfur, phosphorus, and poor aggregate in the concentrate, thereby improving the grade of the concentrate.

◆ Innovation Point Five: Bearing protection

The outer side of the aluminum end cover adopts a wide groove and a structural design with a hidden chamber inside, which prevents the slurry from production from penetrating the joint surface of the shaft end piece and strengthens the sealing of the equipment. The roller shaft end adopts a composite sealing method of multi-groove labyrinth mechanical seal and lip seal ring, which prevents impurities from entering the shaft end and damaging the bearing. And there is a shaft sleeve at the non-drive end, which can effectively prevent damage to the shaft when the bearing is damaged.

◆ Innovation Point Six: Anhydrous ore unloading device

Adopting the double scraper to discharge the mineral in order to enrich the concentrate and improve the density of the concentrate.The scraper is made of wear-resistant material, which can prolong the service life.

◆ Innovation Point Seven: Dual filter flushing system

The washing system controls 8 resining pipes by the control valve.The main pipe has the pipe filter and a double Y-shaped pipe filter, which can keep the nozzle from bloch for longtime operation.

◆ Innovation Point Eight: Feeding device

Feeding device is tube feeding box, connected by flange, which is connected by 2-4 flanges, through the gap-type distribution material and the overflow device. to achieve the purpose of evenly distributing the materials. The 30mm thickness steel pipe at the bottom ensures long-term use without being worn out.

◆ Innovation Point Nine: Transmission

The JCTN magnetic separator is equipped with a frequency conversion speed regulation control device, which can adjust the speed of the equipment according to the properties of the on-site ore, so as to achieve the corresponding mineral processing index.

◆ Innovation Point Ten: High concentrate box

The concentrate box adopts a heightened structure, which can effectively prevent the slurry from splashing out, and a wear-resistant ceramic sheet is pasted on the place that is easy to wear to increase the service life of the concentrate box.

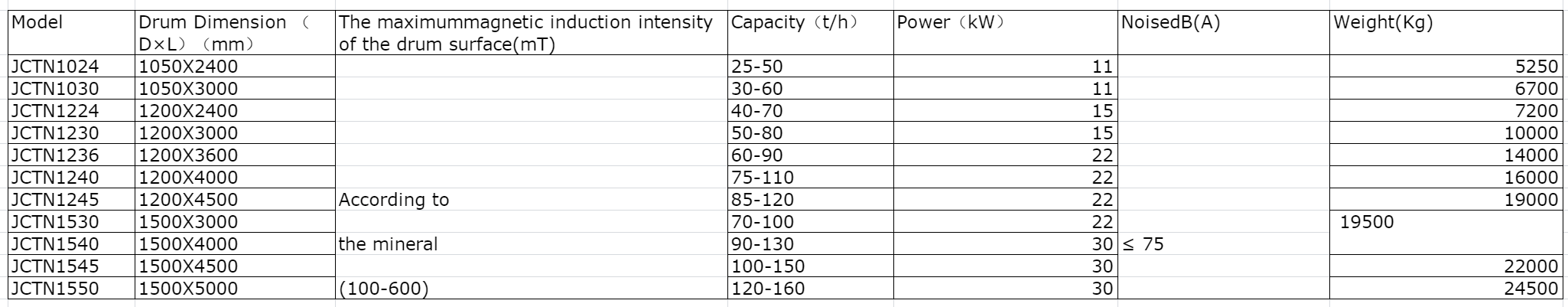

Main Technical Parameters

Note: Please provide ore samples for equipment selection, so as to determine the best separation parameters through magnetic separation experiments.

Six new revolutions in beneficiation process innovation

JCTN Magnetic Separator is a magnetic system structure with large wrap angle and multiple magnetic poles. Combined with magnetic stirring device, rinsing water device, and transmission device equipped with frequency conversion speed regulation, the controllability of JCTN Magnetic Separator is enhanced, according to the specific ore properties, adjust the operating parameters of the equipment to meet the requirements of different process positions for mineral processing indicators. In the beneficiation process, it can realize:

1) Get the qualified concentrate in advance after the first stage of grinding, so as to realize “Get it early”; 2) Increase the scrap rate before grinding, and realize “Throw it early “;

3) The all-magnetic process replaces the reverse flotation process to achieve “Get more”; 4) A single JCTN magnetic separator replaces multiple traditional magnetic separators;

5) Replace traditional selection equipment;

6) Application in ultra-fine iron ore.

Use Case Of

Case 1 : Application of JCTN Magnetic Separator in Benxi Dongfangsanjiazi Mining Industry

The first stage of JCTN1245 magnetic separator is fed by the overflow of the first stage of cyclone, and the grinding fineness is -200 mesh, accounting for 80%. The field use data of one stage of JCTN1245 magnet- ic separator is shown in Table 1.

| product | TFe Grade /% | Yield /% | TFe Recovery /% | MFe/% |

| Concentrate | 48.45 | 46.28 | 81.54 | |

| Tailings | 9.45 | 53.72 | 19.01 | 0.30 |

| Feedings | 27.50 | 100.00 | 100.00 |

Table 1 Field data of a JCTN1245 magnetic separator

It can be seen from the above table that the first stage adopts JCTN1245 magnetic separator, and the fineness is -200 mesh, accounting for 80%. the raw ore grade was increased from 27.50% to concentrate grade of 48.45%, tailings magnetic iron was 0.30%, and tailings magnetic iron was less than 1.00% in response to customer requirements.

A total of 10 sets of JCTN1245 magnetic separators are used for sorting operations in the first stage of the site. The separation of this equipment not only improves the grade of the concentrate, but also throws out most of the tailings, reduces the amount of grinding in the second stage, and saves energy consumption,the on-site use is good and has won praise from customers.

| Product | TFe Grade/% | Yield /% | TFe Recovery /% | MFe/% |

| Concentrate | 63.83 | 79.01 | 95.79 | |

| Tailings | 10.57 | 20.99 | 4.21 | 0.60 |

| Feedings | 52.65 | 100.00 | 100.00 |

Table 2 Field data of second -stage JCTN1245 magnetic separator

It can be seen from the above table that the second stage adopts JCTN1245 magnetic separator, and the fineness is -400 mesh, accounting for 90%, the raw ore grade was increased from 52.65% to concentrate grade of 63.83%, tailings magnetic iron was 0.60%. and tailings magnetic iron was less than 1.00% in response to customer requirements.

A total of 10 JCTN1245 magnetic separators are used in the second stage of the site for separation oper- ations. Through the separation of this equipment, the grade of concentrate ore required by the customer is between 61.00% and 65.00%, and the magnetic iron of tailings is less than 1.00%. Comparing the use of separators in series, one refiner and slag-removing magnetic separator can replace two ordinary magnetic separators, reducing the floor space and operating costs.

Case 2: Application of JCTN Magnetic Separator in Xigang Bolun Mining

The ores of Hami Bolun Mining and Subei Bolun Mining are all primary magnetite. The original process on site adopts three-stage grinding, fine screen classification-three-stage desliming-three-stage weak mag- netic separation process, and the final concentrate grade reach more than 63%; After adopting the JCTN magnetic separator, it can replace the original process of magnetic dehydration tank and weak magnetic separation in series. In the roughing stage, in the case of ensuring the tailings grade, increase the con- centrate grade by more than 2 percentage points, so as to reduce the energy consumption of subsequent grinding, and ensure that the final concentrate grade reaches more than 63%.

There are 16 JCTN1230 magnetic separators in the two processing plants of Hami Bolun Mining Co., Ltd., and each processing plant uses 8 JCTN1230 magnetic separators for on-site beneficiation operations.The beneficiation effect is good, which has been recognized by customers.

Subei Bolun Mining Co., Ltd. has 7 sets of JCTN1230 magnetic separators for beneficiation operations. The beneficiation effect is good, and it has been recognized by customers.

Case 3: Application in ultra-fine iron ore

SINO Mining in Australia belongs to single magnetite, and adopts two-stage grinding and three-stage mag- netic separation process. After two-stage grinding, the particle size of minerals is about 90% of -500 mesh, use the JCTN1230 magnetic separator to replace the two CTB1230 magnetic separators in the original process for the selection operation. Its beneficiation process is shown in the figure.

Its beneficiation indicators are shown in the table:

| Produce | TFe Grade /% | Yield /% | TFe Recovery | Remarks | |

| JCTN1230 magnetic separator | Concentrate | 67.03 | 84.5 | 93.42 |

During the test period, the average value was investigated several times. |

| Tailings | 25.80 | 15.47 | 6.58 | ||

| Feedings | 60.65 | 100.00 | 100.00 | ||

| Application oftwo CTB1230

magnetic |

Concentrate | 66.05 | 98.13 | 99.25 | |

| Tailings | 26.53 | 1.87 | 0.75 | ||

| Feedings | 65.31 | 100.00 | 100.00 | ||

| Concentrate | 65.31 | 88.51 | 95.31 | ||

| Tailings | 24.75 | 11.49 | 4.69 | ||

| Feedings | 60.65 | 100.00 | 100.00 |

According to the data, in SINO Mining, a single JCTN magnetic separator replaces the two CTB1230 magnetic separators in the original process,and can still obtain qualified products with a grade higher than the original concentrate, which shows the advantages of JCTN magnetic separator in the application of ultra-fine powder grade iron ore.