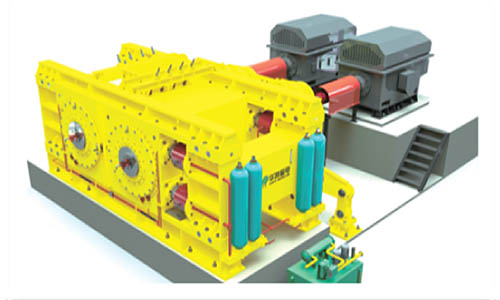

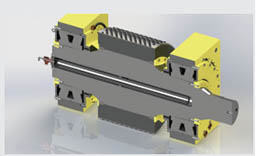

HPGM Series High Pressure Grinding Roll

Product Advantages:

1. Constant pressure design ensures smooth pressure between rolls and ensures crushing effect.

2. Automatic deviation correction, can quickly adjust the roll gap to ensure the smoothness of the equipment.

3. The edge separation system reduces the effect of edge effects on the crushing effect.

4. With cemented carbide studs, long service life, easy maintenance, and replaceable.

5. The valve bank adopts imported components, and the hydraulic system has reasonable design and good reliability.

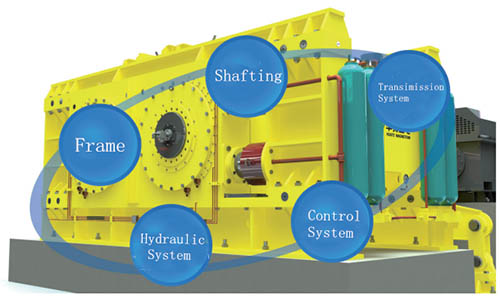

Structural features of HPGR:

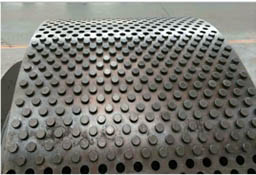

1. New type stud roll surface technology

It adopts high-quality hard alloy studs with high hardness and good wear resistance. The stud arrangement is designed by computer simulation, and the arrangement is reasonable, which can form a uniform material layer between the studs, effectively protecting the studs and roll surfaces, and improving the service life of squeezing roll. The studs are installed with imported special adhesives for easy replacement.

Raw Material

High Quality Wear-Resistant Roll Surface with Studs

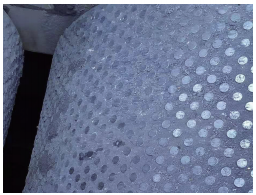

After the materials are extruded, a dense material layer is formed on the roll surface to protect the roll surface.

Material Cake

Separation technology of roll bushing and main shaft

The main body of the squeezing roll is made of high-quality forged steel, and the roll bushing is forged with high-quality alloy steel. The main shaft and the rolls are made of different materials, which improves the toughness of the main shaft and the rigidity of the roll bushing. The service life of the shaft bushing is greatly improved. The replacement of the roll bushing is convenient.

Bearing quick mounting and dismounting technology

High-quality tapered hole bearings are adopted and high pressure oil tank is preformed. The bearing can be easily dismounted through high-pressure oil pump, greatly reducing the difficulty of replacing the bearing and improving the maintenance efficiency.

Multiple combined sealing technology

The bearing seal adopts a variety of J-type plus V-type and labyrinth seals, and the combined sealing technology effectively ensures the sealing effect of the bearing.

High strength frame

The frame is welded with high-quality carbon structural steel. The whole frame strength is three-dimensionally checked, with high strength and good reliability. The frame is processed by integral annealing and the frame deformation is small.

High quality and reliable hydraulic system

According to the crushing characteristics of different materials, the pressure parameters of the hydraulic system are optimized, and a special design is adopted especially for the crushing characteristics of metal minerals such as iron ore and manganese ore. The hydraulic valve group adopts imported famous brand products and is reliable and stable.

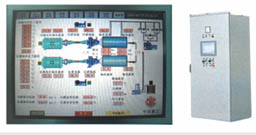

Automated control system and centralized lubrication system

With Siemens PLC and full touch screen, and the overall control scheme, the whole machine can be unattended, and the pressure and various parameters can be easily modified to facilitate the crushing of different minerals. The whole machine adopts centralized lubrication system, which can adjust the lubrication amount and frequency with working conditions.

Project Cases of HPGR: