High Quality Magnetic Separator Powder - Series HS Pneumatic Jet Mill – Huate

High Quality Magnetic Separator Powder - Series HS Pneumatic Jet Mill – Huate Detail:

Work Principle

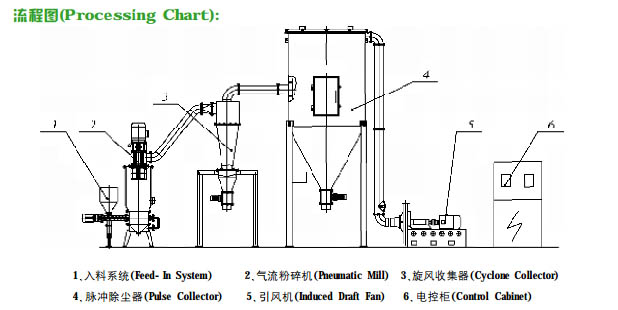

It is made up with milling box, classifier, material-feeding device, air supplying and collecting system. As the material goes into the crushing chamber by way of material feeding device, the pressure air is ejected into the crushing room at high speed through the special designed nozzle. The material accelerates in the jet of high-speed, and then rubs, impacts. The pulverized material goes into classifying room with rising airflow. Owing to the high rotary speed of classifier, the particle is effected by the centrifugal force produced by the classifying rotor and centripetal force generated from the pneumatic stickiness. The coarse particles are swirled back to milling chamber for further pulverization, as the centrifugal force is stronger than centripetal force. The fine particle flows into the cyclone separator along with airflow and is gathered by the collector. The purified air will be vented out from induced draft fan.

Features

With the self-innovation designed energy congregating fluidized bed cyclone ejecting jet mill, it features with lower energy consumption, saving more than 30 percent of energy compared with the traditional jet mill under the same situation. The self-diffluent micro-powder classifier and the vertical impeller with lower rotary speed, steady run and unique sealed structure help the granular size meet the requirement for the granularity. Compared with the other classifiers, this type of machine is of higher cutting precision and classifying efficiency.

The system power is excellent with lower power and unit energy-consumption.

Running in wholly-sealing negative pressure, the complete system features with automatized control and simple operation.

Product detail pictures:

Related Product Guide:

High-quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is constantly observed and pursued by our business for High Quality Magnetic Separator Powder - Series HS Pneumatic Jet Mill – Huate, The product will supply to all over the world, such as: Algeria, Gambia, Bangladesh, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.