Good Quality Powder Processing Equipment - Process flow of Quartz sand Production Line – Huate

Good Quality Powder Processing Equipment - Process flow of Quartz sand Production Line – Huate Detail:

Technical parameters

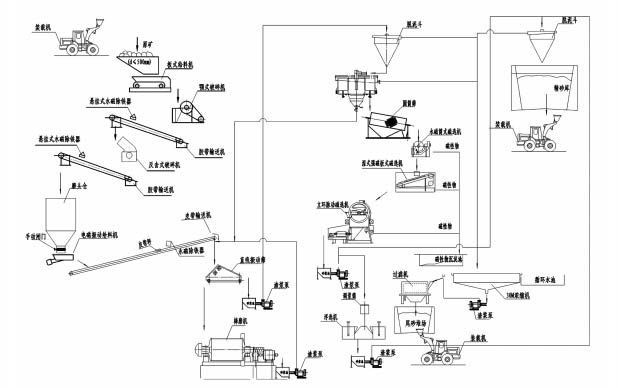

Firstly, Quartz fall under the hopper,quartz stone is broken into the coarse material after primary crushing, and be transported by belt conveyor for further crushing to the second crushing machine, then the smaller stone will be taken into the vibrating screen for screening out two type size quartz stones, exceed size stone will be returned to crushing machine again. Sieved material into the rod milling machine, Materials from the rod milling machine to classify through the cylinder screen. in the sieve to return to the rod milling machine, Sieved material to eliminate the tramp iron by high intensity magnetic separator, and then into the Vertical Ring High Gradient Magnetic Separator to remove the residual mechanical iron and associated iron , usually after two procedures of separating, quartz sand iron content can down to below 0.07%, Finally ,the qualified pulp through the hydraulic desliming slot to take off the mud, and then dehydrated to become the qualified quartz sand products.

In the production line, Rod mill and the High Gradient Magnetic Separator is one of the core equipment, this production line is a high degree of automation, low operation cost, high crushing efficiency, energy saving, large output, less pollution, easy maintenance, the final quartz sand has the uniform size, good grain shape and reasonable size distribution, which can meet the national standards of construction machine-made sand.

Processing Chart

Raw ore → crushing (coarse crushing, medium crushing and fine crushing) → pre screening and inspection → ore washing → rod grinding → classification → dehydration → weak magnetic separation → strong magnetic separation → classification → dehydration → end product

Product detail pictures:

Related Product Guide:

We have been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Good Quality Powder Processing Equipment - Process flow of Quartz sand Production Line – Huate, The product will supply to all over the world, such as: Singapore, Guinea, Amman, Our products have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll provide the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.