-

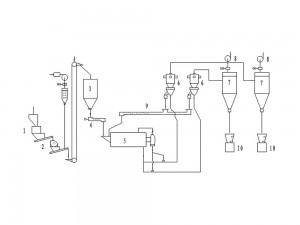

Good Quality Powder Processing Equipment - Ball Mill &Horizontal Classifier Production Line – Huate

Application ◆Soft material: calcite, marble, limestone, barite, gypsum, slag etc. ◆Hard material: quartz, felspa, carborundum, corundum, fine cement etc. Characteristics ◆Designed to the standards of ultrafine mineral manufacturing. ◆Optimized length-to-diameter factor of ball mill ◆Grid plate at the end of the ball mill discharges powder fluently, no dilating and no necessary to cool the tube ◆Grinding medium chosen according to customers’product, high filling rate and efficiency ◆Perfe... -

Factory Cheap Hot Electromagnetic Iron Separator - Electromagnetic elutriation separator – Huate

Technical characteristics ◆ Special design with adjustable magnetic intensity. ◆ Stable and effective performance. ◆ Adopting wear-resistance electric valve to prolong the equipment service life. ◆Low power & water consumption, no noise and no need of lubrication. ◆ High processing capacity that is 3-5 times than the traditional magnetic separator or re-election machine. ◆ Remote & site control. -

Factory Cheap Hot Dry Magnetic Separator - Flat Ring High Gradient Magnetic Separator – Huate

Technical Features 1. This series of products with advanced structure, reliable work, easy operation and maintenance, long work period, good separation effect features. 2. It has wide adaptability to the fluctuation of feed particle size, concentration and grade, and has achieved the ideal goal of large beneficiation ratio and high recovery. -

Special Design for Drum Magnetic Separator - Series DCFJ Fully Automatic Dry Powder Electromagnetic Separator – Huate

Technical Features ◆ Simple connection: The main engine is vibrating during operation. Connected with the pipe or the canvas. bag, the material can be fed into and discharged from the equipment. ◆Separate and remove the uneasy flowing fine powder. Under the effect of the vibration motor, the material, which is < 200 μ m or with high humidity, can go through the screen mesh. ◆Process the material with high temperature: the standard model can process the material with 70℃; while the special mo... -

Top Quality High Intensity 3 Stages Roller Magnetic Separator - TCTJ Desliming & Thickening Magnetic Separator – Huate

Separating and desliming for overflow product of classification after first grinding. Pulp thickening before the second grinding and filtering. The magnetic mineral’s desliming before feeding into the fine screen and reverse flotation; the final concentration of magnetite. Structure Working principle After the pulp is fed into the feed box,it can be fed into separation area directly.The magnetic mineral is absorbed on the surface of the magnetic drum after magnetization and transferred to mi... -

China New Product High Intensity Wet Magnetic Separator - Fully Automatic Dry Powder Electromagnetic Separator – Huate

Features ◆The magnetic circuit adopts computer simulation design with scientific and rational magnetic field distribution. ◆Both ends of the coils are wrapped by steel armor to raise the utilizing rate of magnetic energy and increase the magnetic field intensity in the separation area by more than 8%, and the background magnetic field intensity can reach 0.6T. ◆The shell of excitation coils are in wholly sealed structure, moisture, dust and corrosion proof, and can work in harsh environments.... -

Factory Free sample Laboratory Suspension Drum Magnetic Separator - WHIMS – Huate

Technical Features 1). Maximum magnetic intensity: 20000GS. 2). Water-saving at least 8000 cubic meter per year. 3). Extherm can be controlled with 30℃. 4). Oil-cooling system to replace of the old-fashion water-cooling. 5). Compact structure, easy to install and operate. 6). The exciting coil is completely dipped into the transformer oil to prolong the service time. Structure Separation Process Diagram Patent technical innovation point 1 Coils Special design of exciting coil, there are th... -

Chinese Professional Coal Magnetic Separator - Series SGB Wet Panel Strong Magnetic Separator – Huate

Outstanding Advantages 1. High magnetic intensity. The magnetic system is made up of the rare earth NdFeB magnets with high performance. It has a very wide poly pole face, lots of magnetic poles. It’s with a very high magnetic induction ability and a very high magnetic gradient. The magnetic intensity in some part can reach 17000Gs. 2. Large magnetic panel with a wide magnetic and gravity separation area. At present, the largest width for the panel is 2500mm, and its largest length is 3000mm.... -

Leading Manufacturer for Iron Ore Dry Magnetic Separator - Series JCTN Raising Cocentrate grade and Decreasing Dregs Content Drum Permanent – Huate

Usage: Desliming for the overflow material after the first mill or concentrate before the second mill and filter or desliming before the magnetite fed in to the fine screen and the reverse flotation:final beneficiation for the magnetite. Features 1. Adopt the pipe-feeding device and over-flow system to feed the material evenly. 2. With 200~270° magnetic element and the multi-pole design to achieve the ideal beneficiation indicator, the magnetic element structure can be designed accordingly. 3... -

Factory making Belt Conveyor Magnetic Separator - The Global latest generation 1.8T evaporative cooling WHIMS – Huate

Features 1. The evaporative cooling technology is a newly high efficient and cost effective cooling technology. It exchanges the heat by the phase transition of its cooling media with high insulation and low boiling point, and then transfers the heat in order to cool the heating coils. 2. The Institute of Electrical Engineering of China Academy of Sciences has started the application research on evaporative cooling technology since 1958. Cooperating with many units, it develops in succession ... -

Hot New Products Magnetic Stirrer – DC Electromagnetic Stirrer – Huate

Technical specifications ◆ Adapting computer simulation design, this product has the features of unique magnetic circuit, high magnetic intensity and large magnetic penetration depth. ◆ Adapting electrical pure iron material with high permeability and high saturation magnetic induction intensity, reducing the hysteresis loss, and improving the stability of the magnetic field. ◆ The use of advanced varnished insulating and curing processing technology, protecting the coil will not be affected ... -

Best quality Wet Magnetic Separator - The Global latest generation 1.8T evaporative cooling WHIMS – Huate

Features 1. The evaporative cooling technology is a newly high efficient and cost effective cooling technology. It exchanges the heat by the phase transition of its cooling media with high insulation and low boiling point, and then transfers the heat in order to cool the heating coils. 2. The Institute of Electrical Engineering of China Academy of Sciences has started the application research on evaporative cooling technology since 1958. Cooperating with many units, it develops in succession ...