-

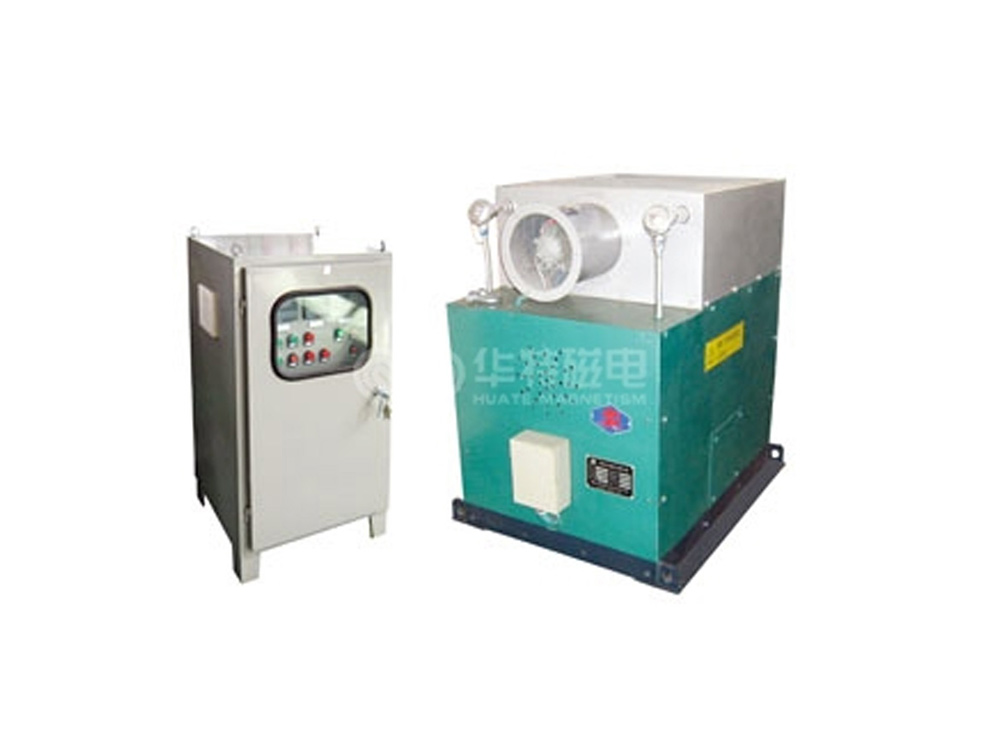

Cheap PriceList for China Newest Metal Sorting Machine Refining and Magnetic Sorting of Transported Products

Application: For large thermal power plants, coal transportation ports, coal mines, mines, building materials and other places that require high iron removal, and can work normally in harsh environments such as dust, humidity, and severe salt spray corrosion.It is the most common cooling method for electromagnetic field in the world.

-

Factory made hot-sale China Elutriation Magnetic Separator

Application: This product is used for the concentrate of magnetite to effectively remove the monomer gangue and other impurities to upgrade the Fe% in concentrate.

-

Competitive Price for China Vertical Ring High Gradient Magnetic Separator for Minerals

Application: It can be used in wet processing – 1.2 mm (- 200 mesh of 30 ~ 100%) red ore(hematite and limonite, siderite, etc.), manganese ore, ilmenite, chromite, tungsten ore and other kinds of weakly magnetic minerals, and metallic minerals, such as quartz, feldspar, nepheline ore, kaolin for removing impurity iron and purification.

-

Factory supplied China Heavy Equipment Ball Mill/Grinding Mill/Rod Mill

Application: The rod mill is named after the grinding body loaded in the cylinder is a steel rod. The rod mill generally uses a wet overflow type and can be used as a first-level open-circuit mill. It is widely used in artificial stone sand, ore dressing plants, chemical industry the primary grinding industry in the power sector of the plant.

-

Cheap price China High Efficiency Wet Permanent Magnetic Separator of Drum Type Cts (N, B) -1218

Application: This countercurrent roller magnetic separation equipment is specially designed for reclaiming the magnetic media in the coal-washing plant.

-

Quoted price for China Drum Magnetic Separator for Iron Ore Benefication Plant Gold Mining Hematite Magnetic Separator Machine

Application: For the steel mill, cement plant, power plant and some other department, used for removing iron from slag and protecting the roller , vertical miller and crusher.It is used in good environment.

-

Special Design for China Biobase Mini Hotplate Magnetic Stirrer

On-Line Energy-Saving And Environmental Protection Permanent Magnetic Stirrer.

-

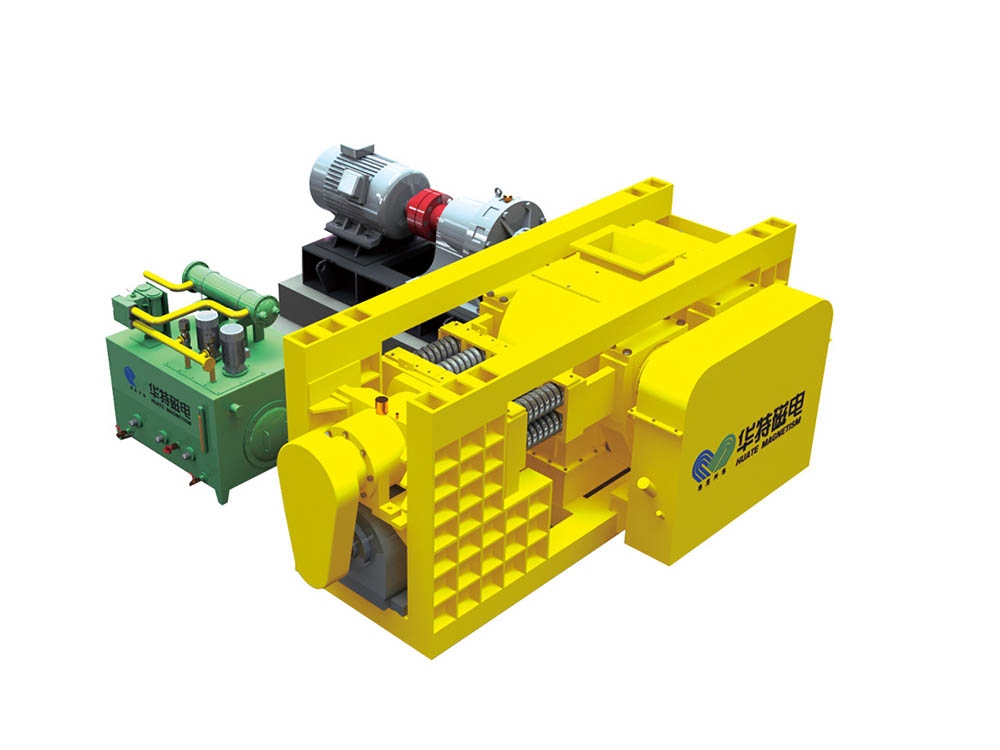

100% Original China High Quality Mining Machinery Stone Crushing Crusher Replacement Blow Bar

Application: The Single Driving High Pressure Roller Mill – Series PGM is specially designed to pre-grind the cement clinkers, the mineral dross, the steel clinkers and so on into small granules, to ultra-crush the metallic minerals (iron ores, manganese ores, copper ores, lead-zinc ores, vanadium ores and others) and to grind the non-metallic minerals (the coal gangues, feldspar, nepheline, dolomite, limestone, quartz, etc.) into the powder.

-

Fast delivery China Superior Quality Wet Magnetic Drum Separator for Iron Ore

Application: This countercurrent roller magnetic separation equipment is specially designed for reclaiming the magnetic media in the coal-washing plant.

-

Good quality China Thermostat Controlled Chocolate Butter Cylinder Volume 300L

Energy-Saving And Environmental Protection Permanent Magnetic Stirrer(side-installed).

-

High Performance China Iron Ore Wet Type Drum Magnetic Separator

Application: Mainly used in the cement industry: the back-grinding coarse powder after the powder separator and the clinker pre-pulverization before the fine powder before iron removal, to prevent iron. Iron particles accumulate in the mill, thereby improving the production efficiency of the mill and the specific surface area of the cement: iron removal before the cement filling process can. The iron impurities mixed in the cement are automatically cleaned and discharged to ensure the stable operation of the production.

-

OEM Manufacturer China High Intensity Mineral Separator Vertical Ring Electromagnetic Separator

Application: Remove the impurities and purify the non-metallic minerals, like silica sand, feldspar, kaolin etc. It can also be used in other industries, like to deal with the wasted water in steel plants, power-generation plants, and to cleanse the polluted chemical raw materials.