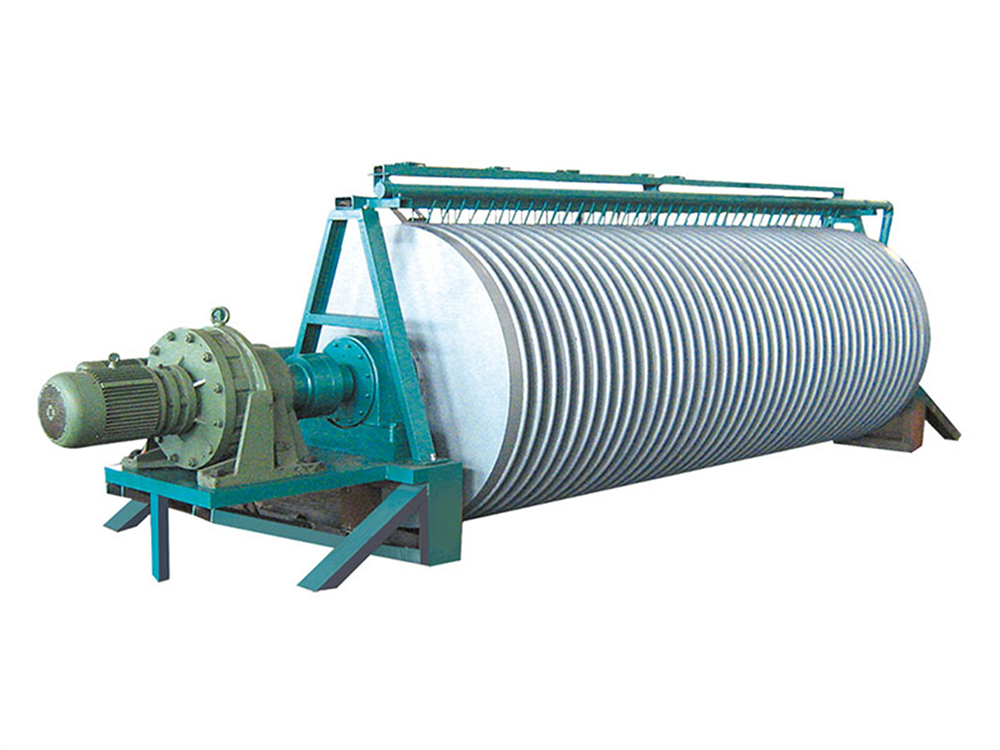

HTECS Eddy Current Separator

Application

◆ Purification of waste aluminum

◆ Non-ferrous metal sorting

◆ Separation of scrapped automobiles and home appliances

◆ Separation of waste incineration materials

Technical Features

◆ Easy to operate, automatic separation of non-ferrous metals and non-metals;

◆ It is easy to install and can be effectively connected with new and existing production lines;

◆ NSK bearings are used for high-speed rotating parts, which improves the stability of the equipment;

◆ Adopting PLC programmable control, start and stop with one button, easy to operate;

◆ Using intelligent touch control system, frequency conversion control, more stable operation;

◆ The whole machine adopts special technology and fine manufacturing, and the noise and vibration are extremely small when the equipment is running.

Working principle

The separation principle of the eddy current separator is to use the magnetic drum composed of permanent magnets to rotate at high speed to generate an alternating magnetic field .

When a metal with electrical conductivity passes through a magnetic field, an eddy current will be induced in the metal .

The eddy current itself will generate an alternating magnetic field and is opposite to the direction of the magnetic field generated by the rotation of the magnetic system drum, while non-ferrous metals (such as aluminum, copper, etc.) will jump out along its conveying direction due to the opposite effect, so as to separate from other non- metallic substances such as glass and plastic, and realize the purpose of automatic separation .

Structure diagram of eddy current separator

1- Vibrating material distributor 2- Driving drum 3- Conveying belt 4- Separation magnetic drum 5- Non-metal outlet 6- Non-ferrous metal outlet 7- Protective cover 8- Frame