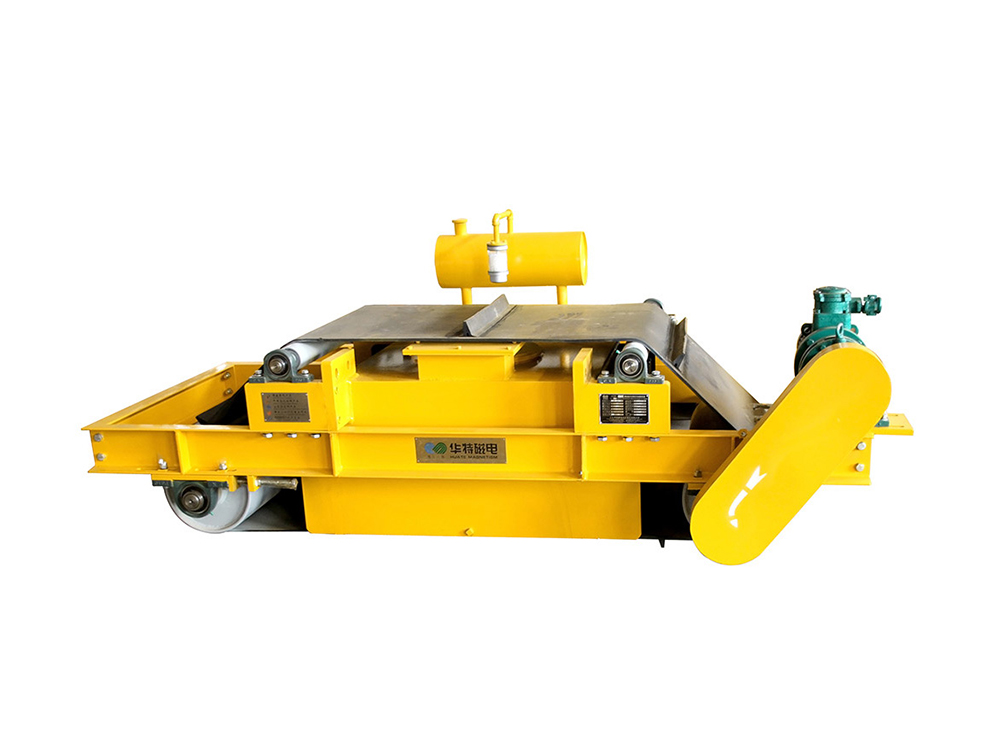

DCFJ Fully Automatic Dry Power Electromagnetic Separator

Application:

This equipment is used to remove weakly magnetic oxides,crumb iron rust and other contaminants from fine materials.It widely applies to material purification in refractory material,ceramics,glass and other non-metallic mineral industries,medical,chemical,food and other industries.

Technical Characteristics :

◆The magnetic circuit adopts computer simulation design with scientific andrational magnetic field distribution.

◆Both ends of the coils are wrapped by steel armor to raise the utilizing rate of magnetic energy and increase the magnetic field intensity in the separation area by more than 8%, and the background magnetic field intensity can reach0.6T.

◆The shell of excitation coils are in wholly sealed structure, moisture, dust and corrosion proof, and can work in harsh environments.

◆Adopting oil-water compound cooling method. The excitation coils have fast heat radiating speed, low temperature rise and small thermal reduction of magnetic field.

◆Adopting magnetic matrix made of special materials and in different structures, with large magnetic field gradient and good iron removal effect.

◆Vibration method is adopted in the iron removal and discharge processes to prevent material blockage.

◆Material barrier is set up in the material division box to solve the material leakage around the flap plate for clear iron removal.

◆The shell of the control cabinet is made of high quality steel plate and with structure of double layer door. It is dust-proof and water-proof with IP54 rating.

◆The control system adopts programmable controller as the core control component to control each actuating mechanism so that they run in accordance with the process flow cycle with high automation level.

◆The control system is equipped with advanced human-machine interface technology, which can have a high speed real-time communication with programmable controllers through Host Link bus or networking cable.

◆The on-site datas are collected by sensors and transmitters.According to the beneficiation process parameters given by the user, advanced PID control theory (constant current) is applied to quickly achieve the rated excitation field strength of the control system in both hot and cold states of the equipment.It solves the shortcomings of previous equipment during hot operation, such as a decrease in magnetic field strength and slow excitation rise speed etc..

Main technical parameters :

| Model

Parameter |

DCFJ-150 |

DCFJ-300 |

DCFJ-450 |

DCFJ-600 |

DCFJ-800 |

DCFJ-1000 |

|

Background magnetic field intensity(T) |

0.4/0.6 |

|||||

|

Diameter of working chamber(mm) |

φ150 |

φ300 |

φ450 |

φ600 |

φ800 |

φ1000 |

|

Excitation current(ADC) |

≤ 90 |

≤ 100 |

≤ 130 |

≤ 160 |

≤ 160 |

≤ 335 |

|

Excitation power(kW) |

≤ 25 |

≤ 35 |

≤ 48 |

≤ 58 |

≤ 70 |

≤ 120 |

|

Motor power(kW) |

0.09×2 |

0.75×2 |

1.1×2 |

1.5×2 | 2.2×2 |

2.2×2 |

|

Weight(kg) |

≈ 4200 |

≈ 6500 |

≈ 9200 |

≈ 12500 |

≈ 16500 |

≈ 21000 |

|

Processing capacity(t/h) |

0.2 ~ 0.5 |

1~2 |

2~4 |

4~6 | 6~8 |

8~ 10 |