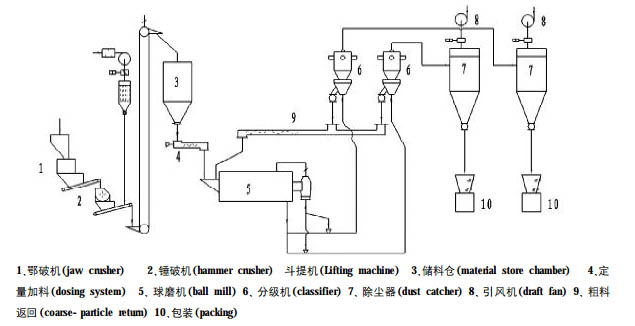

Ball Mill &Horizontal Classifier Production Line

Application

◆Soft material: calcite, marble, limestone, barite, gypsum, slag etc.

◆Hard material: quartz, felspa, carborundum, corundum, fine cement etc.

Characteristics

◆Designed to the standards of ultrafine mineral manufacturing.

◆Optimized length-to-diameter factor of ball mill

◆Grid plate at the end of the ball mill discharges powder fluently, no dilating and no necessary to cool the tube

◆Grinding medium chosen according to customers’product, high filling rate and efficiency

◆Perfect match between drive station and energy consumption of grinding, energy saving to the fullest extent possible.

◆Forming a closed system with classifier, with negative pressure transport, without powder pollution.

Note: All of the parameters above are according to 1250 mesh GCC.

As different material from different places, the parameter is just for your reference.

Application Site