-

Series GYW Vacuum Permanent Magnetic Filter

Scope of application: Series GYW vacuum permanent magnetic filter is a cylinder type external filtering vacuum permanent magnetic filter with upper feeding, which is mainly suitable for dehydration of magnetic materials with coarse particles.

-

Series RCYG super-fine magnetic separator

Application: For the enrichment of iron grade of powdery materials such as steel slag, or the removal of ferromagnetic impurities in materials.

-

Series CS Mud Separator

CS Series Magnetic desliming tank is a magnetic separation equipment which can separate magnetic ore and non-magnetic ore (slurry) under the action of gravity, magnetic force and upward flow force. It is mainly used in the benefication and other industries. The product is optimized by computer, with high efficiency, good reliability, reasonable structure and simple operation. It is an ideal equipment for slurry separation.

-

RCYA-5 Conduit Permanent-magnetic Iron Separator

Application: For remove pollutants such as weak magnetic oxides and rusty scales in liquid and slurry streams, and purify materials in industries such as medicine, chemical papermaking, non-metallic ore, and refractory materials.

-

Series HSW Horizontal Jet Mill

HSW series micronizer air jet mill, with cyclone separator, dust collector and draft fan to constitute a grinding system. Compressed air after being dried is injected into grinding chamber quickly by the injection of valves. At connection points of big amount of high-pressure air currents, feed materials are collided, rubbed and sheared repeatedly to powders. The grinded materials go into classifying chamber with uprising air flow, under the condition of lashing forces of draught. Under strong centrifugal forces of high-speed rotating turbo wheels, coarse and fine materials are separated. Fine materials in line with size requirements go into cyclone separator and dust collector through classifying wheels, while coarse materials fall down to grinding chamber to be grinded continuously.

-

RCYA-3A Conduit Permanent-magnetic Iron Separator

Application: Iron removal in liquid and slurry low-pressure pipelines, purify materials in non-metallic ore, papermaking, ceramics and other industries.

-

Series HS Pneumatic Jet Mill

Series HS pneumatic mill is a device adopting high-speed airflow to fine dry material.

-

Series HPD Pneumatic Jet Mill

The materials are brought into crushing chamber by compressed air through material-feed jet. The compressed air distributes in several air jets uniformly to release transonic air current, which forms strong eddy flow in the mill chamber to force the particle in the material to collide and rub.

-

RCDEJ Oil Forced Circulation Electromagnetic Separator

Application: For the port of coal transportation, big thermal power plant, mine and building material. It can also work in the harsh environment such as dust, humidity, salt fog.

-

Series HJ Mechanical Super Fine Pulverizer

The equipment is a new-type of grinder. It has a dynamic disc and static disc. The material is grinded with the impact, friction and cutting forces on the static disc by the high rotary speed of the dynamic disc. Under the negative pressure, the qualified powder enters into classifying zone and is gathered by the collector while the coarse material returns for further grinding.

-

Series RCDD Self-Cleaning Electric Magnetic Tramp Iron Separator

Application: To remove the iron tramp from the various material on the belt conveyor before crushing.

-

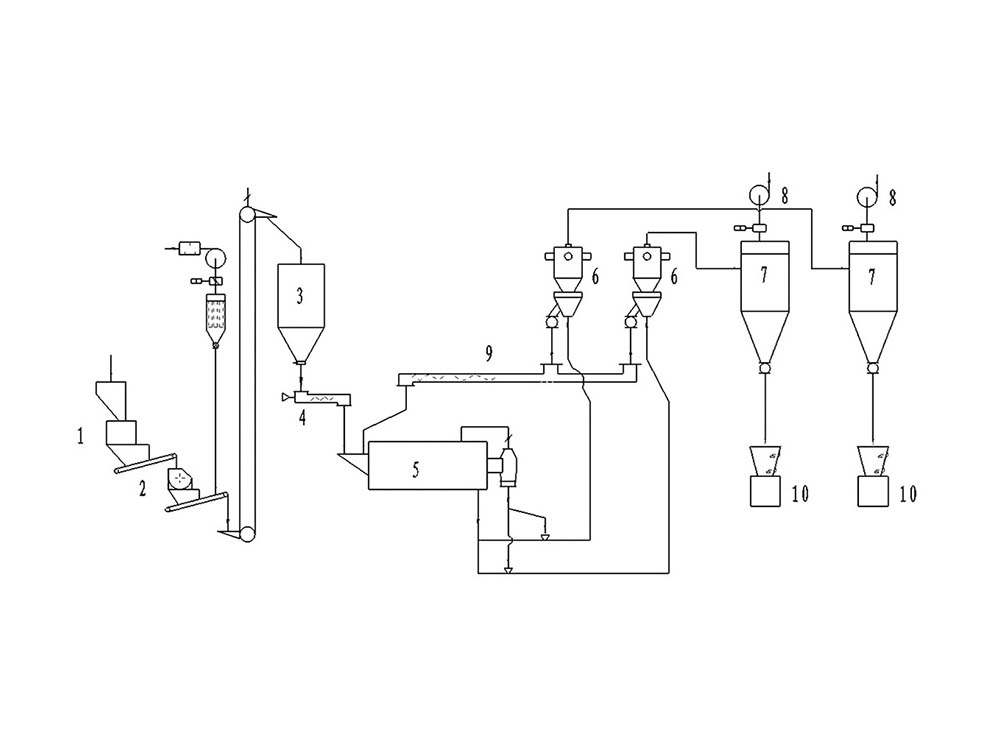

Ball Mill &Horizontal Classifier Production Line

The whole process of the technology ensures that the emission of dust is lower than 40 mg / m3 and 20 mg / m3 after production, by adopting the combination of dust collector, draft fan and pneumatic conveying system, the strict control of every dust concentration point, and the use of high-quality filter material. The equipment can prevent dust leak and make the whole technological process negative and clean.