-

Mid – Field Strong Semi – Magnetic Self – Discharging Tailings Recovery Machine

Application: This product is suitable for the separation of magnetic minerals. It can enrich the magnetic minerals in the tailing slurry, suspend the magnetic ore powder for regeneration, or remove the magnetic impurities from other suspensions.

-

Updraft Magnetic Separator

Application: This machine is a new type of high efficiency and energy-saving magnetic separator suitable for different belt specifications. Mainly used for scrap steel, steel slag iron, direct reduction iron plant iron, iron foundry iron and other metallurgical slag iron.

-

Series CTG Energy-Saving and Environmental Protection High Intensity Roller Permanent Magnetic Separator

Application: Removing the weakly magnetic impurities from the fine and coarse powder materials, it has been widely used in ceramic, glass, chemical, refractory industry and so on. Meanwhile it also can be used in processing hematite, limonite ect, weakly magnetic minerals.

-

Series DCFJ Fully Automatic Dry Powder Electromagnetic Separator

Application: Separate the weak magnetic oxides and crumble-like ferrous rusts from the fine powder materials. It is applied to purify the materials in the nonmetallic mineral industries, like ceramics, glass and refractory material; the medical, the chemical, the foodstuff and other industries.

-

Series CXJ Dry Powder Drum Permanent Magnetic Separator

Series CXJ dry powder drum permanent magnetic separator (from the single drum to four drums, 1000~10000Gs) is a magnetic separation equipment used to remove the iron impurities from the dry powder material continuously and automatically.

-

Series YCBG Movable Magnetic Separator for Dry Sand

Application and structure: Series YCBG movable magnetic separator for dry sand is medium intensity magnetic separation equipment and can be used to rich magnetic minerals from the powdery ore, marine sand or other lean ore or to eliminate magnetic impurity from powdery materials. This equipment is composed of grizzley, distributing device, frame, belt conveyor, magnetic separator and so on. The separation drum is made by stainless steel plate. Employing multi-magnetic poles and large wrap angle design for magnetic system, and NdFeB magnet as magnetic source. Its characteristic is high intensity and high gradient. The revolution of the separation drum can be adjusted by the electromagnetic regulator speed motor.

-

Series RCGZ Conduit Self-cleaning iron Separator

Application: Mainly used in the cement industry: the back-grinding coarse powder after the powder separator and the clinker pre-pulverization before the fine powder before iron removal, to prevent iron. Iron particles accumulate in the mill, thereby improving the production efficiency of the mill and the specific surface area of the cement: iron removal before the cement filling process can. The iron impurities mixed in the cement are automatically cleaned and discharged to ensure the stable operation of the production.

-

Series RCYF Deepen Pipeline Iron Separator

Application: For the removal of powdery, granular, and block materials in the cement, building materials, chemical, coal, grain, plastic, and refractory industries, etc. Connect to the conveying pipeline and install vertically.

-

RCDZ2 Super Evaporative Cooling Self-Cleaning Electromagnetic Separator

Application: For large thermal power plants, coal transportation ports, coal mines, mines, building materials and other places that require high iron removal, and can work normally in harsh environments such as dust, humidity, and severe salt spray corrosion.

-

Series HMDC High Efficiency Magnetic Separator

The equipment is a kind of countercurrent drum magnetic separator specially designed to recover magnetic medium. With the computer-simulating design, form strong magnetic force and high gradient magnetic system, magnetic wrap angle is 138° The reasonable structures of the equipment, which can produce rational mineral pulp flow, remarkably enhance the recovery rate of magnetic minerals.

-

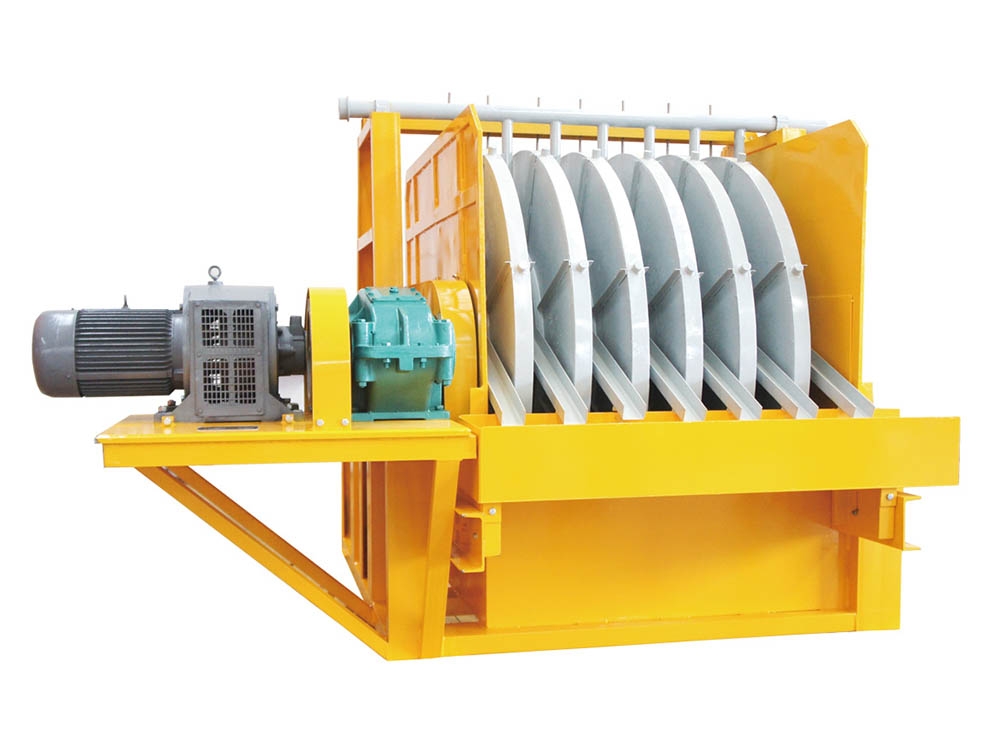

ZPG Disk Vacuum Filter

Applicable Scope: It is used to dehydration processing for metal. Nonmetal solid and liquid products.

-

Series GYW Vacuum Permanent Magnetic Filter

Scope of application: Series GYW vacuum permanent magnetic filter is a cylinder type external filtering vacuum permanent magnetic filter with upper feeding, which is mainly suitable for dehydration of magnetic materials with coarse particles.