-

Permanent Magnetic Stirrer

Energy-Saving And Environmental Protection Permanent Magnetic Stirrer(Install under the furnace).

-

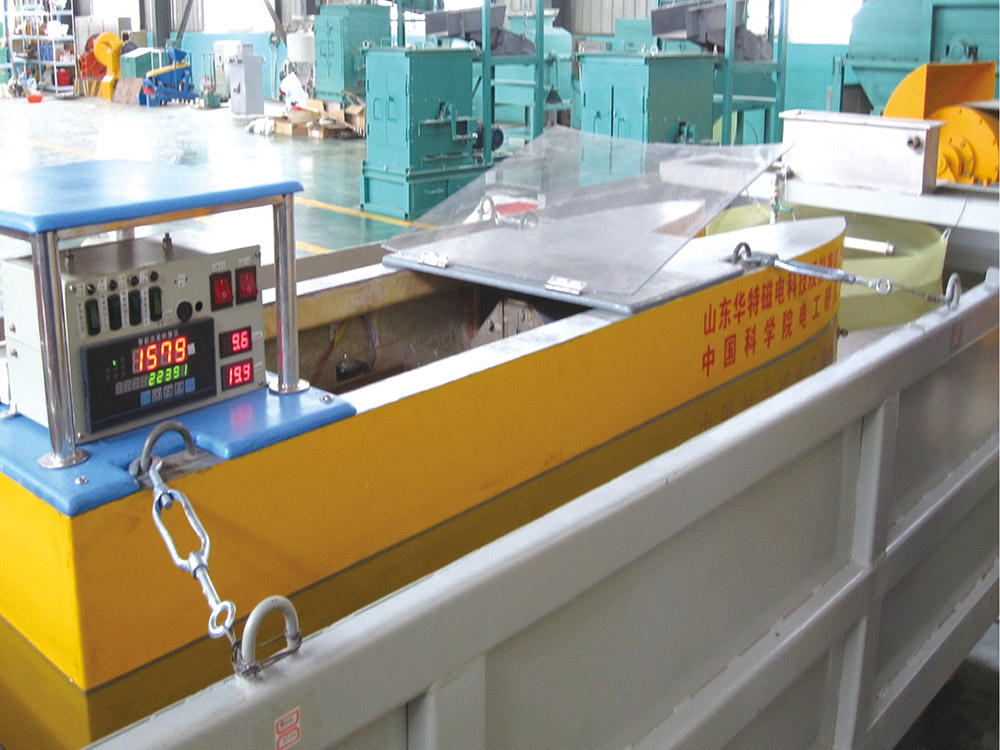

Energy saving and environmental protection side type permanent magnetic stirrer

Energy-Saving And Environmental Protection Permanent Magnetic Stirrer(side-installed).

-

Energy saving scrap melting furnace permanent magnetic stirrer

Energy-Saving And Environmental Protection Permanent Magnetic Stirrer for Scrap-Melting Fumace.

-

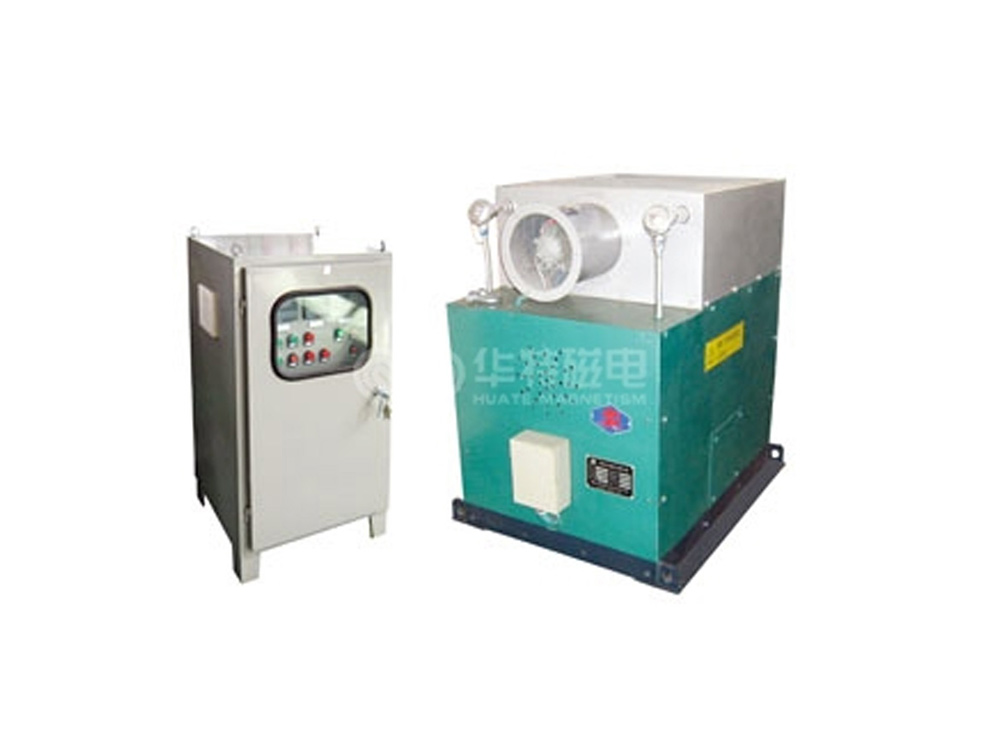

Energy saving and environmental protection inline permanent magnetic stirrer

On-Line Energy-Saving And Environmental Protection Permanent Magnetic Stirrer.

-

Ball Mill & Vertical Classifier Production Line

Application

Soft material: calcite, marble, limestone, barite, gypsum, slag etc.

Hard material: quartz, felspa, carborundum, corundum, fine cement etc.

-

Completely non-ferrous metal separation production line

Applicable Scope: The sorting system equipment design absorbed the advanced technology and structure of similar foreign products, for recycling non-ferrous metal, instead of manual separation, largely to improve the product efficiency. The system can automatically separate iron, stainless steel, non-ferrous metal and non-metallic materials from materials, which is a kind of material energy to be reused.

-

Floc Separator

Applicable Scope: Widely used in large lakes, reservoirs, landscape, water, urban sewage, to remove the eutrophication of nitrogen, phosphorus and cyanobacteria.

-

Series HMZ Vibration Mill

Working principle: The materials are impacted by high frequency vibration in the milling chamber. Strong affecting force is offered through milling matrix (ball, rod, forge, etc), and materials will be grinded under friction, collision, shearing and other forces.

-

Electromagnetic fluid sea oil slick separation and recovery device

Application: CNOOC, CNPC, Sinopec, offshore oil drilling platforms at sea, more than 300000 tons of oil pier at sea.

-

Complete Equipment Production Line for Dry Discharge of Tailing

Application Scope:

1. Sand washing, machine-made sand, mixing station mud, mud dewatering, construction mud, dewatering of piling mud;

2. Dewatering and dry discharge of non-metallic mineral tailing, dewatering of non-metallic mineral pulp;

3. Dry discharge of iron ore tailing and dewatering of concentrate powder. -

Series HTK Iron Separator for Magnetic Mine

Application: It can match with the conveying belt, and eliminate the magnetic impurities, such as the original ore, sinter ore, pellet ore, block ore and others. It can separate ferromagnetic materials with the least mine to protect the crushers.

-

HPGM Series High Pressure Grinding Roll

Practical Application Scope:

1. Medium, fine and ultrafine grinding of bulk materials.

2. In the mineral processing industry, can be placed before the ball mill, as a pre-grinding equipment, or make up a combined grinding system with a ball mill.

3. In the oxidized pellet industry, can replace the commonly used damp mill.

4. In building materials, refractory materials and other industries, have been successfully applied in cement clinker, limestone, bauxite and other grinding.