2020 High quality Heated Magnetic Stirrer - DC Electromagnetic Stirrer – Huate

2020 High quality Heated Magnetic Stirrer - DC Electromagnetic Stirrer – Huate Detail:

Technical specifications

◆ Adapting computer simulation design, this product has the features of unique magnetic circuit, high magnetic intensity and large magnetic penetration depth.

◆ Adapting electrical pure iron material with high permeability and high saturation magnetic induction intensity, reducing the hysteresis loss, and improving the stability of the magnetic field.

◆ The use of advanced varnished insulating and curing processing technology, protecting the coil will not be affected by dust erosion, the coil has a good insulation properties.

◆ With positive rotating and negative rotating alternatively, the speed and time can be arbitrary adjusted in a high degree of automation.

◆ Adapting special air duct design and forced air cooling, the coil heat release fast and with low temperature rise.

◆ Low operation cost, less power consumption, energy saving and environmental protection.

◆ Solution stirring intensity can be adjusted flexibly, the eddy current effect is good, stirring depth and scope is large.

◆ It is equipped with advanced remote control system, the automation degree is high, it has manual and automatic function, the operation is simple and convenient.

Technical specifications

There are multilayer ventilation slot between the induction coil of DC electromagnetic stirrer to pass cooling air, on both sides of the coil is provided with a wind guide cover, adapting two coils air inlet symmetrical cooling model, the coil tempera-ture rise is low and magnetic field attenuation is small, further increased the penetration depth of furnace bottom and aluminum solution.

Rotating hollow shaft is provided on the magnetic yoke between two coils, there are many air vents on the top of hollow shaft, external has fixed wind guide ring, the cooling air go through wind guide ring and air vents into the inside of coil, the cooling resistance is small and heat release is fast.

The DC coil adopts a double layer disc winding process & 180 ℃ heat resistant and curing process, the coil has strongly adapt ability, stable & reliable operation and high safety.

Using the high performance conductive ring, the equipment works stable and reliable and has a long service life.

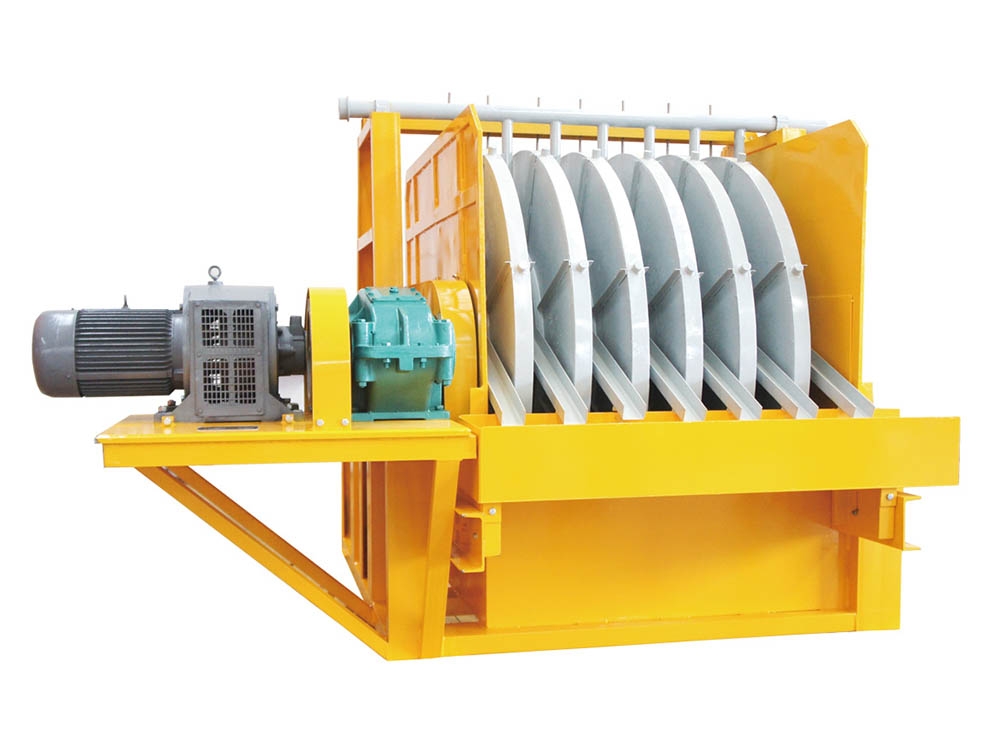

Product detail pictures:

Related Product Guide:

We also offer product sourcing and flight consolidation services. We've got our personal factory and sourcing office. We can easily present you with almost every style of merchandise linked to our merchandise range for 2020 High quality Heated Magnetic Stirrer - DC Electromagnetic Stirrer – Huate, The product will supply to all over the world, such as: Tajikistan, Seattle, Philadelphia, Our products have mainly exported to south-east Asia Euro-America, and sales to all of our country. And depending on excellent quality, reasonable price, best service, we've got got good feedback from customers overseas. You are welcomed to join us for more possibilities and benefits. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.